I want to offer readers option manufacturing with your own hands of a screw drill designed for drilling wells under the foundation of any structure.

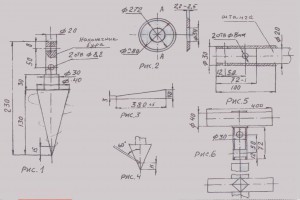

On the turning machine, the steel head of the drill is made (Fig. 1) and a steel disk with a thickness of 2.2 mm with a diameter of 280 mm. The disk along the line A-A (Fig. 2) is cut into two parts. It will be a bore knives. Cut the conical plate with a thickness of 2.2 mm (Fig. 3) is the future spiral of the bora. Rates from the top of the cone of the head 15 mm, put to the drier head on the edge, a narrow side, a plate at an angle of about 60 ° relative to the axial line and grab it (Fig. 4).

On the turning machine, the steel head of the drill is made (Fig. 1) and a steel disk with a thickness of 2.2 mm with a diameter of 280 mm. The disk along the line A-A (Fig. 2) is cut into two parts. It will be a bore knives. Cut the conical plate with a thickness of 2.2 mm (Fig. 3) is the future spiral of the bora. Rates from the top of the cone of the head 15 mm, put to the drier head on the edge, a narrow side, a plate at an angle of about 60 ° relative to the axial line and grab it (Fig. 4).

Further work simplifies the gas burner for heating the plate and its bending to the head cone clockwise. If there is no gas burner, heated the plate can be carried out on the usual gas stove.

Due to the suspension of the plate turned out to increase the height of the spiral of the bora.

To the drum head weld knives, as shown in the photo.

The car is joined by its tip (Fig. 5) and attached to it with two M8 screws.

At the other end of the bar, the cross is mounted (Fig. 6), with which the boring rotates. The set of 6ou needs to be made 3 rods (630, 800, 1170 mm). The second bar is used when it is already uncomfortable, bending, rotating the boring.

Start a discussion ...

Start a discussion ...