With the onset of cold, many are thinking about how better to insulate their home and make it more comfortable for wintering. In addition to the main thermal insulation works with walls, roof and floor, you can create an additional heat source - a gas cylinder oven. The practice of constructing such devices has decades, and during this time many schemes and methods for creating functional furnaces from simple gas cylinders were invented. In this article we will tell about the most popular of them.

Features of cylinders

Homemade ovens from gas cylinders are significantly superior to the efficiency and efficiency of similar structures from other girlfriends. This is explained by the form of the balloon - it is ideal for pyrolysis processes. The quality of the furnace depends on its firebox. As practice is shown, the perfect form for the flue compartment is the sphere. Plus, it should have two holes in it: for the entrance of oxygen and removing gases and smoke into the chimney. An oblong gas cylinder cylinder allows you to implement all the necessary requirements for the perfect firebox without significant deformations.

Types of furnaces

An old cylinder, aimlessly dusty for years somewhere in a barn, can serve as a basis for creating a furnace for home. And the most remarkable thing is that it is not limited to some kind of variety - you can choose the design to your taste. Each type of gas cylinder furnace features a degree of complexity of assembly, efficiency and principle of work. So, the most popular option is all familiar burzhuyk. We will talk about its advantages, disadvantages and method of installation a little later.

The oven is also popular, since the cost of spent oil is very small and saves on fuel. You can build a gas stove from a gas cylinder, but newcomers are better to start with something easier, since a similar design is very complex and requires large temporary and labor costs. Below in the photo shows a diagram of such a rocket stove and how it looks in the interior.

The main rule when assembling the furnace from the gas cylinder, with your own hands, is the information of financial investments to a minimum. It is also important to provide the convenience and safety of the design of the structure, especially if it is located in a residential building.

Choosing a balloon

Not any gas cylinder will be suitable for the manufacture of the stove. First of all, it should be all-metal, since explosion-proof composite products are not distinguished by heat resistance. The capacity of the balloon also plays the value - from a small 5-liter flask is unlikely to be an effective stove. Such a cylinder can be applied except to create a tank for a fuel-fuel furnace. From the cylinders of 12 l and 27 liters, the ovens with a capacity of 2-3 kW and 5-7 kW, respectively.

But, the most optimal option for the construction of a high-quality furnace capable of drying a small private house is a 50-liter balloon 30 cm in diameter and 85 cm in height. Its volume is quite enough for almost waste-free combustion of any kind of fuel. In addition, such cylinders are still in demand and a good product can be purchased quite inexpensively. The technologies of the furnaces described below provide for the use of such cylinders.

Useful advice: If you got a balloon with a valve, then it is better to choose it for the stove, and not a product with a valve. Using the valve, it is convenient to adjust the combustion power of the furnace, feeding more or less oxygen into the flue compartment.

It is also worth mentioning the cylinders for industrial gases of 40 liters. To create stoves, they are better not to use, because they are too narrow, heavy and bulky. From small promblelons for 2-10 liters, some make hiking stoves, but they are suitable only if you go to the car - products too much weigh.

Bourgeois from the cylinder

As we said, the most popular stove, which can be collected from the cylinder, is considered to be burzhuyk. For its manufacture, a small balloon is suitable for 12 liters or 27 liters, but you can take 50 liters of capacity if the country house is heated. Bourgehog is suitable for heating a small room, such as a country house, garage or workshop. If you built a new country house, but did not have time to spend the heating communications to the cold, the burzhuyk will be your salvation for the winter.

The burzhuyki device from the cylinder is pretty simple: the furnace with the grill, pondered and chimney. You can put it in any room, from which it is convenient to remove the chimney outward. The design is characterized by compactness and security. She very quickly warms up and immediately gives heat into the room. Some attach to the top of the stove cooking surface to prepare food or warm water.

However, there are one serious minus at the bourgeois - no matter how thick the walls of the oven, over time it burns out. And the more often to use the stove, the faster it will happen. For this reason, it is better to make such a furnace as a temporary or spare heat source, for example, in emergency situations or for additional heating.

On video - oven made of gas cylinder for garage heating:

In the video material, a furnace of two gas cylinders is demonstrated above, but to create an effective design of enough and one. In addition to the balloon, you will need steel corners (furnace legs), metal grille for grate, sheet steel 3-4 mm thick, door and chimney pipe of the desired length. From the tools you need a Bulgarian, a welding machine, metal scissors, a hammer, a screwdriver and a perforator with a set of metal drill.

How to make a gas cylinder oven:

- Unscrew the rim with a crane located at the top of the cylinder. If you cannot unscrew, it can be carefully knocked out with a hammer.

- Fill the cylinder with cold water or immerse it up to the middle of the pit in the ground.

- At the top, make a hole in size from the door of the future furnace.

- Using the welding machine, make a frame for the door from steel corners and attach it to the cylinder.

- Attach the door to the frame in the position in which it will be fixed, and make a bolt hole in the corners. Screw the door to the frame.

- Where the bottom of the stove is, cut the hole for the grate and brew the grid.

- At the cut opening from 3 sides, attach the sidewalls from sheet steel. As a result, you should get a box without top. We weld it to the bottom of the balloon, turning the open side to the door - through this passage you will remove ash. It is important that the box is completely sealed.

- Install the metal flap for regulating the oxygen entering the furnace.

- To the bottom of the balloon, weld the legs of the steel corners.

- On the wall located in the opposite side of the door, cut the hole in accordance with the diameter of the chimney pipe. Equip the crankshaft, then warm will leave the oven is not so fast.

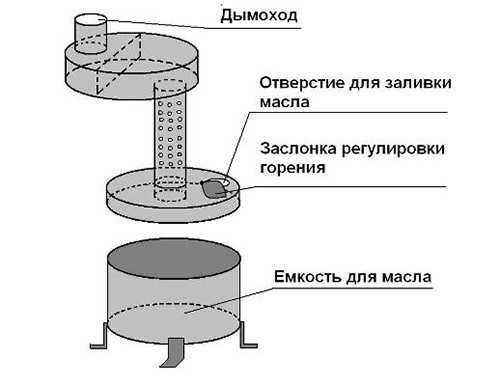

Oven on working out

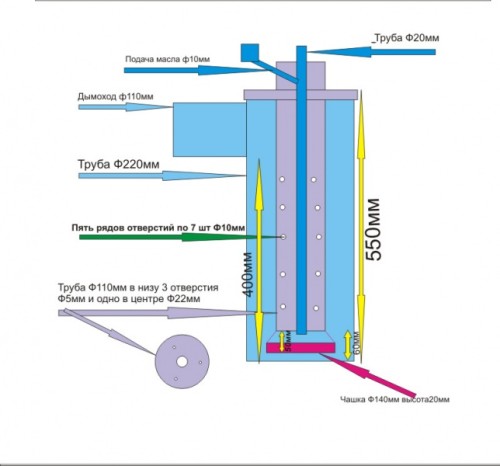

The oven on working out from the gas cylinder to make a little more difficult than the burzhuyk, but this work is quite feasible even for beginners of self-touching. If you do everything according to the instructions, it will get a very effective device that is able to quickly heat the garage, a small country house or cabinet.

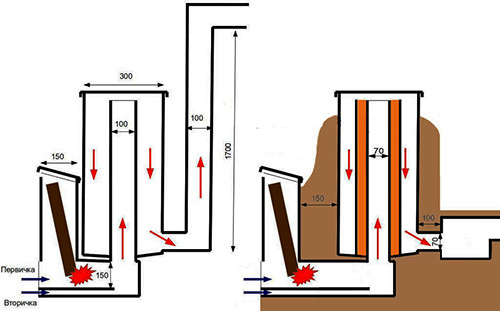

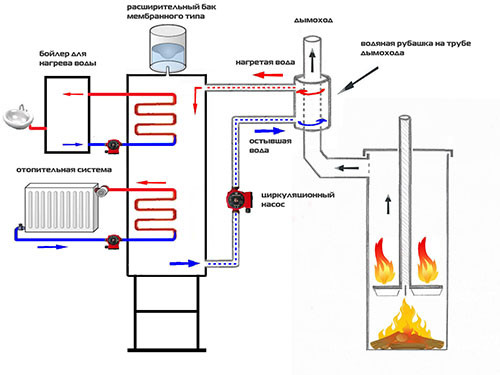

The principle of operation of the furnace on the work is as follows: you pour oil into the fuel compartment and ignite it, air is dosed through the air choke, which affects the intensity of burning. The heat of combustion of oxygen here is mainly spent on evaporation - the pairs are rushed up and fall into the reactor with perforated walls. Fresh air penetrates through the holes, which only enhances the combustion of oil vapors, as a result of which the temperature grows, and the pyrolysis process begins. Not only oil is burning, but also a pair, so there is practically no waste of such a furnace. In the upper part of the pyrolysis compartment, the gases are practically burning and exited into the hurrying chamber consisting of two compartments: pyrolysis evaporations are burned in the first, which maintain the temperature in the second due to the high temperature and the absence of oxygen nitrogen oxides of gases decompose on oxygen and nitrogen. Oxygen supports surviving gases, and the furnace temperature is consistently supported by about one level.

The outlet in the chimney tube from the afterburning chamber should be located as far as possible from the partition - about 20 cm. The efficiency of such a furnace is about 80%, which is one of the highest rates among homemade heating devices.

As a rule, 50 l cylinders use cylinders for the manufacture of ovens on spent oil. They are cut in the 2: 1 ratio - the smaller part goes to the creation of the reservoir, and large on the hurry chamber. The result is a stove with a capacity of up to 30 kW. However, due to the specific fuel, all possible security measures should be taken - burning workout can do a lot of trouble. Do not install such a furnace in the residential room and stop accessing children and pets to it.

Long burning furnace

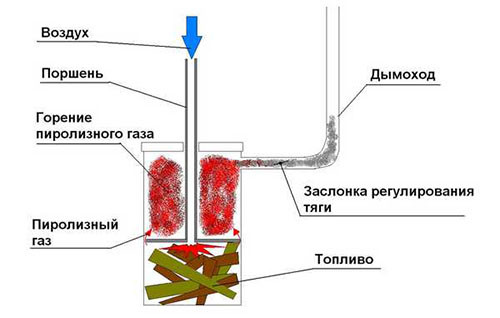

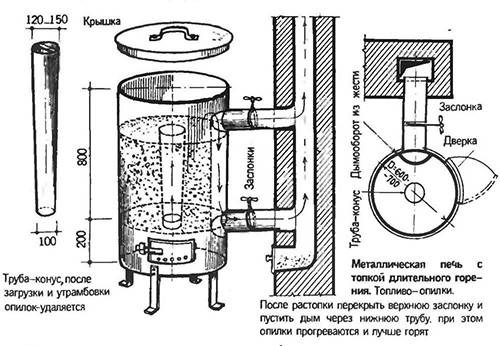

For the manufacture of long-burning furnaces from the gas cylinder, you will need a large container by 50 liters. Any wood product can be used as a fuel, ranging from sawdust, ending with old furniture and branches of garden trees. Since fuel in such furnaces burns a thin layer near the surface itself, they are also called long surgery stoves. The pyrolysis process can be carried out in two ways: in a separate small chamber, followed by burning gases in the afterburning chamber (furnace of separate combustion), or gases will switch to a spacious heated buffer compartment, where they will store (combined furnaces). To ensure the maximum possible efficiency and in the first, and in the second case, it is recommended to warm the air that enters the pyrolysis area.

Bunch bubonia

The oven of long burning with the funny name of the bunch is very popular in the circles of summer houses and the liveshis. In this design, the pyrolysis process focuses under a special oppression. The image below shows the scheme of such a furnace, based on which it is possible to understand the principle of its device and work.

The efficiency of the bubfoni can be 85% or more, while the heat transfer duration from a single fuel load is 18-24 hours. If it is necessary to constantly monitor the usual burzhuyka, otherwise you risk frozen, then the bunch can be visited only once a day, which is very convenient. The humidity of the fuel for the furnace should be not more than 12%. In the process of combustion, you can throw more firewood or chips, but it is extremely recommended to stop the stove until the fuel combustion is completely combustion.

Important: For the manufacture of bubfony furnace, it is necessary to use a 50 l cylinder with a diameter of 30 cm, since it provides the minimum allowable volume.

Such a furnace is very economical, despite the fact that it is possible to make it at home:

- It is easiest to collect a big ballon oven. Cut it the top and breed to cover the clamps or the stops so that they hold it on the body.

- For the manufacture of the piston, you will need a metal "damn" with a diameter of a little less than the inner diameter of the cylinder. The main thing is that the piston with the "pan" moved freely inside the furnace, and pyrolysis gases could come out through the lateral gaps between it and the inner wall of the chamber.

- In addition to the pancake for the piston, a pipe is needed through which oxygen will go to the bottom compartment, and several segments of the steel corner (metal strips) - they need to be accepted to the back of the "pancake".

- In the center of the pancake, make the opening, the diameter of which corresponds to the diameter of the pipe.

- To the bottom side of the "pancake", we weld some pieces of the steel corner - they will not allow the piston close to the firewood and overlap the oxygen supply. Place the metal "struts" so that they go from the inner opening to the outside (straight or bend). According to the channels received on the "pancake" will go air, so it is necessary that it fall into the hole, otherwise the fuel will not burn.

- The pipe, which will go air, should be longer than the cylinder body by 7-10 cm. Insert the pipe into the central hole in the "pancake" and hermetically breed it. For greater strength, you can add rigidity ribs. Otherwise, after a while, "damn" will begin to deform from extremely high temperatures.

- In the center of the lid, make a hole with a diameter of a little more piston pipe - the piston will pass through it. Tightness is not needed here - it is necessary that oxygen flows inside.

- In the cylinder case just below the lid, make a hole for the chimney pipe. To ensure a consistently good craving, use a pipe with a diameter of at least 10 cm. The horizontal section of the chimney should reach about 40 cm, then set the knee and direct the pipe up. The total height should be at least 2.5 m (the higher the better).

Useful advice: It is best to make a chimney team, and start collecting it not from the stove, and on the back side - from the roof (then it will be more convenient to disassemble it for maintenance and repair). Many prefer to install a glass with revisions in order not to disassemble the chimney to remove soot.

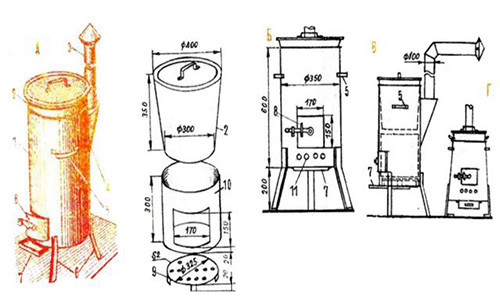

Gas cylinder oven: photo

Finally, we suggest you look at the drawings of ovens from gas cylinders and see which designs can be built with your own hands.

This is how "Bunch" looks inside:

Start a discussion ...

Start a discussion ...