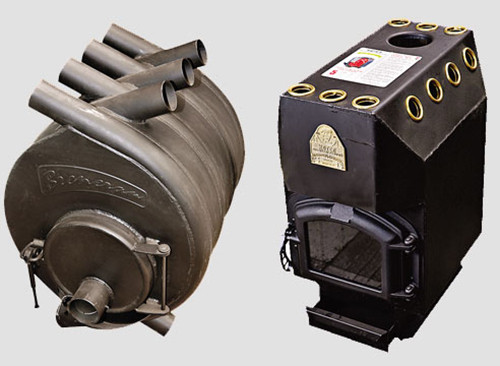

Buleryan - a very unusual stove, which is able to once and forever solve the problem of the heating of the country house, garage, greenhouses and any other room. It provides a quick heating with minimal fuel costs, which allows you to significantly save time and money. It is worth such pleasure quite expensive, but if you like to work with your hands and are not afraid of difficulties, it is quite realistic to make the bake of the buleryan with your own hands.

Device and principle of operation

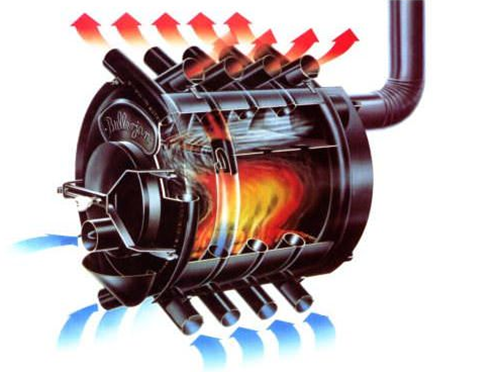

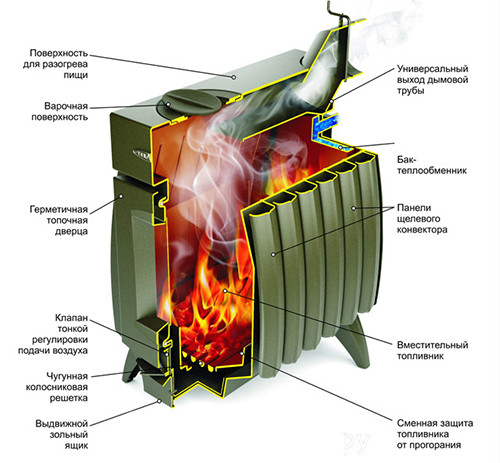

This unusual stove has found applied in many areas. So, it can be used not only for the heating of residential premises, greenhouses, garages and workshops. In European countries, the saunas and baths are heated! This is a pretty good hybrid of old-good bourgeitogo with a long burning stove. The operation of the device is based on forced convection. In the firebox leads a series of curved pipe arc above and below. In the lower openings, cold air circulates, which, passing through the furnace, quickly heats up and comes through the upper holes. Thus, a rapid warming of the room occurs.

The temperature that is formed in the process of work of the buleryan is so high that it can easily warm up even a small two-storey house. In addition, it is possible to combine the oven with a water circuit of heating, having received double benefits - a warm home and hot water. We will tell about the water heating of a bulery chain a little later, and while we consider the furnace device in more detail.

Buleryan is capable of functioning in two modes. First, the stove is quickly warmed up and evenly distributes heat around the room, and then goes into slow combustion mode. At first, fuel will have to put very often, but only to warm up the buleryan. When it happens, the firebox can be "feeding" only twice a day.

When the firewood is completely burned in the furnace part, the combustion products on convection pipes are moved to the secondary combustion compartment, where the air-gas mixture is hurred at extremely high temperatures. As a result, the efficiency of the device is at least 80%. The visual principle of the Booleryman can be viewed in the video below:

Interesting: Buleryan or Buller was invented by Canadian techniques specifically for lumberjacks. Since the deforestation of the forest is usually conducted in the cold season, and the Canadian climate can be more severe Russian, then the loggers are in the literal sense to survive in extreme conditions. They needed an effective, but compact furnace, which could be easily taken with me and install at the time. Plus, the furnace should be easy to operate, in order not to explain the newcomers every time, how to handle it and eliminate the risk of errors. Well, of course, the cost of such a device must be acceptable. Having collected all the requirements, the Canadians came up with a small, highly efficient and easy-to-service stove, which in a short time conquered not only lumberjacks, but also owners of private houses far beyond Canada.

If you have been removed to assemble a bulenyan with your own hands, you should warn you - it's not easy. In addition to professional welding skills, you will need a lot of special equipment and patience car. Get ready for the fact that you can not build such a furnace in one day, and you have to tinker. Some details can be ordered in a locksmith workshop, others - to buy in the finished form.

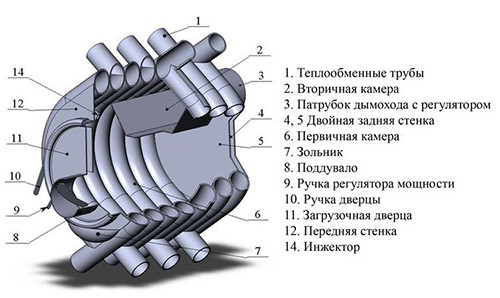

As the basis of the furnace was taken scheme of convection air boiler or simply a carrier. The wide furnace door must be completely sealed. It passes a confusion with a throttle, which regulates power. Sometimes the throttle handle is equipped with a special temperature scale with a restrictive emphasis so that the furnace does not overheat. If necessary, the choke can be blocked for repayment or suppress the thrust.

To improve the efficiency and performance of the buleryan, it is necessary to carefully insulate the chimney. Most often, it is used for this inexpensive mineral wool, laying its layer with a thickness of at least 3 mm. You will also need to build up for air intake in the furnace. You can also organize a ash bar just in case, however such a stove almost leaves waste. Due to the double rear wall, the efficiency of work is enhanced. In separate models, you can observe a two-layer case.

Making a furnace

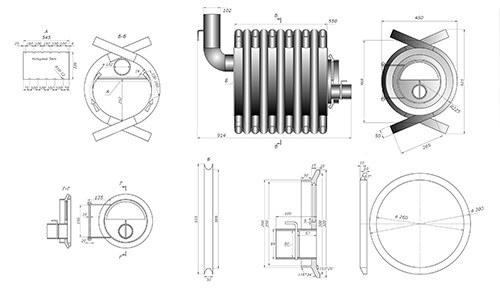

Once again we remind you that the manufacture and installation of a buleryan in the house is only experienced by experienced welders, so if you are unsure of your abilities, it is better not to risk and buy a finished design. First of all, prepare a detailed booleric scheme. At the end of the article, you will find a visual example and can use it as a basis for the construction of your own oven, changing the size if necessary.

What instruments will be needed primarily:

- bulgarian with disks;

- drill with metal nozzles;

- pipe bender for steel pipes;

- welding machine.

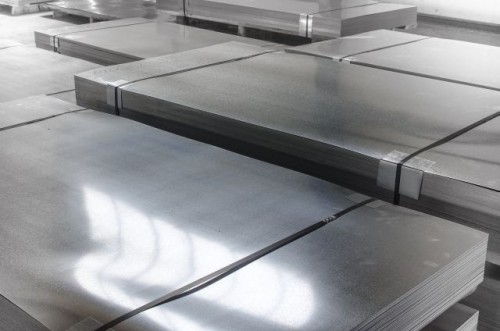

The case is more complicated with the material. The first priority is to find high-quality steel that can withstand the continuous effect of extremely high temperatures. Boiler steel in our time it is not so easy, but if there is such an opportunity, it will be the best option for the buleryan.

Materials for the construction of the furnace:

- sheet steel 4 mm size 1x2 m;

- sheet steel 6 mm in size 0.4x0.7 m;

- tube 100 mm long 4 m;

- pipe 350x4 mm;

- pipe with a diameter of 57 mm 10 m long;

- tire 40x40;

- fittings (handles, loops, etc.).

How to make a buleryan:

- Take the pipe 57 mm and bend it with special pipe bend.

- Cut a bent pipe up to 1.2 m.

- Bend the pipe 100 mm. As a result, there should be 8 pipes of 4 pieces with identical bends. It turns out that the depth of the stove will be approximately 456 mm.

- Make T-shaped tubular tap. It will be located behind the furnace and perform a double function - to output gases and collect condensate (from the top end will go smoke, and from the bottom - drip water).

- Mock the tap of the bottom of the pipe, where water drip. Thus, when condensate is accumulated, it is possible to substitute the container, open the tap and drain the water.

- Insert the damper into the removal. It will allow you to regulate the power of thrust and control the speed of burning fuel.

- Similar to the detail in pissed on the front door.

- To reliably fix and adjust the dampers, it is recommended to install a high-quality powerful spring. It will pour the damper inside the pipe, not allowing it to open it by chance. The progress of the dampers should be clearly supplied at 90 °.

- From pipe 350x4 Cut two pieces of 40 mm long. Cut the seam and expand the cut out. Inserted a 40x40 tire into the gap. As a result, you will have 2 rings entering each other. This item is needed for the construction of the covers of the buleryan.

- Second ring install on the front side of the furnace.

- Welcome rings using what is more for the door.

- Make a third ring with a length of 40 mm and a thickness of 2 mm - it will enter the ring on the door. The remaining space between the details fill asbestos.

- It is very important to ensure the absolute tightness of the door so that gas generation and natural air circulation occurred.

- Air movement will be carried out by means of pipes, but this will occur only with complete tightness. It will also not hurt to fade on the door seals. In the first two nozzles, make small slots and insert injection pipes in them. They are needed for communication with fuel compartment and more intensive burning.

- Weld a frame of bent pipes. The first to be placed pipes with injection parts, then the rest.

- Make partitions from thick chimney 6 mm. Cut the blanks using a template or pattern.

- Treat the spacecraft with the welding machine between convection nozzles.

- The lock on the door is a classic eccentric that is fixed to the wall and presses the door. It is very difficult to make it, and to make it qualitatively, you need to have a lathe. If you do not have it, you can make a detailed drawing and order a detail in the workshop.

- Insert the air injector into the top of the wall.

- So you can adjust the strength of the thrust in another way.

- We weld the legs for the furnace and the necessary accessories. Check the blank for stability on a flat area and if you need to adjust the form. Only after you were convinced of the correct location of all parts, you can taste all the joints and slots between the elements.

- It remains only to melt the stove and enjoy the results of the work done.

You can use an ordinary old boiler as the basis of a buleryan. It will turn out excellent walls. Thus, you will save yourself from a large number of welds. However, the option described above looks more aesthetically than the pumped tubes of the barrel.

It is also worth mentioning how to choose the oven dimensions in accordance with the area of \u200b\u200bthe room, which should be heated. Focus on the technical characteristics of the capacity and the rate of heating the volume of air in a minute. Thus, the heating rate of the buleryan with a furnace in 40 liters is about 4.5 m³ / min. Accordingly, if you increase the volume of the furnace for 10 liters, that is, up to 50 l, then the warming speed will grow to 9 m³ / min. The oven with a 100 l per minute will warm up 18 m³ of air.

Safety

We will not be able to mention the safety technique when using a buleryan. The device of this furnace is quite complicated, if you figure it out, but anyone can learn how to use it. One of the requirements of Canadian lumberjacks to the heating furnace was fire safety, but nevertheless, dealing with fire, it is almost impossible to reduce the risk to zero.

Installation of a bulery furnace should be carried out with a distance of at least 40 cm from the walls of the house. It is recommended to place a device on a small elevation - this will increase the thrust and reduce the risk of fire. As a rule, a special metal podium is built under it, and under the furnace, leaf steel, so that the sparks or random coals do not burn the floor.

Overview of the buleryan furnace in video format:

Water buleryan

As we promised, it was a turn to tell about Water Buleryan. Indeed, why not adapt such an excellent design for water heating? Such models are already available, but their effectiveness and appropriateness leaves much to be desired. As one famous constructor of submarine said: "This is a vivid example of the victory of technology over common sense."

Manufacturers of such "water-workers" or did not teach physics at school, or forget about the basic principles of work and the initial design of the structure - air heating. Air and water are completely different matter with different characteristics of heat capacity. So, in water this figure is 800 times higher than that of the air, therefore, it needs more energy or more time to warm up. The design of the buleryan with side heating at all wishes is unable to do it.

And yet there is a way to heat the water in the buinlane for heating - make burning in the firebox more intense. However, the efficiency will be significantly lower. If such a fact does not scare you, consider briefly, how to adapt air bulers under aquatic heating.

For example, we have 2 batteries, each of which is 4 pipes, and the power of the furnace is 10 kW. With intensive firebox, the air will warm up in such a furnace to a maximum of 160 °. Nutya on two pipes are ordinary metal corrugations and connecting them to pipes passing through the furnace, we get a water heating device. Vertically or horizontally put these pipes - no difference. Water will take 2.5 kW.

If the volume of the firebox is 80-100 liters, and this compartment is isolated by two layers of steel, then half an hour, the buleryan heat water up to 60-70C, and this temperature will be maintained subsequently. If we compare with conventional electric boilers, then from the tane heating consumes from 3.5 to 5 kW.

Interesting: Stories have known many cases when the same thoughts came into the heads of completely different people, and the same inventions simultaneously appeared in different parts of the world. Even at the beginning of the 20s of the 20th century, Professor I. Butakov also invented Buleryan. He just attached to the top of the burzhuyki with the thermal screen the simplest shoe. Modern furnaces created on the concept of Buttakov Mightweight compete with Canadian bulers, and this competition is moving from the market to homemade workshops - to make the stove Butakov is much easier than the classic bulenean. The image below shows the device of such a design.

Buleryan: photo

Data Drawings Buleryan You can take the basis for building a design with original sizes. This is a small furnace, intended for heating garages, greenhouses and workshops. If you want to make a furnace for home, increase the dimensions of 1.5 times or more.

Start a discussion ...

Start a discussion ...