The characteristics of the climate of Russia, in particular the northern regions, have long made an obvious fact that it is much more profitable to warm the walls of the house than annually to pay for heating devices. That is why the tenants of apartment and private houses resort to the use of polystyrene foam for insulation of walls. In this article we will talk about the features of using the material and how to avoid frequent errors when installing it.

General characteristics

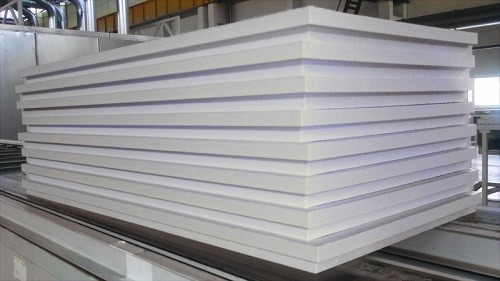

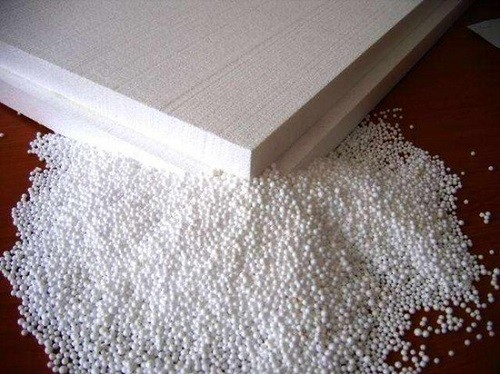

Special technology manufacturing insulation allows you to make it more durable, energy efficient and durable compared to other popular materials. Thus, polymer granules are mixed with a special foaming substance, resulting in a chemical reaction. Next, the mixture is subject to heat treatment with an extruder, which provides uniform mixing of components and the uniformity of the substance. Then make plates of the necessary sizes, after which it freezes and turns into reliable thermal insulation material.

The advantages of polystyrene foam:

- high strength;

- maintains the initial form throughout the entire life period;

- does not miss moisture;

- low vapor permeability;

- fireproof (does not burn and does not support burning, but with long-term exposure to high temperatures can melt and challenge);

- high resistance to chemicals;

- environmentally safe;

- low cost.

Myths about polystyrene foam

In the modern market of building materials, you can find many varieties of insulation, but expanded polystyrene is considered one of the best. Since he appeared relatively recently, then immediately "around" myths and misconceptions, which is not so simple. Most of them are caused by a violation of installation techniques and specific use. For example, for laying it is necessary to use special glue, and for the insulation of walls from the inside or facades, a different stove thickness is needed. Floor insulation is polystyrene or the creation of roofing pie with his participation also have its own characteristics.

Consider the most common myths about polystyrene foam:

- Extruded (foamed) polystyrene foam is better than usual - by and large, foamed polystyrene foam is the same foam, only a slightly different technology was used in production - the effect of high temperature and pressing. In fact, the difference in the thermal conductivity indicator is negligible and is only 0.002 units. Therefore, the usual and foamed expanded polystyrene is almost the same way well protected from cold. However, fooling, inexperienced builders prefer "high-quality" products, which, in turn, has a lot of flaws. First, the cost is much higher than that of ordinary polystyrene foam. Secondly, the foamed material can bentified under the influence of high temperature. Thirdly, insulation with extruded polystyrene foam requires the use of special glue, which does not fit the usual plates.

- Mineral wool is better and cheaper than polystyrene foam. The fact that Minvat is cheaper, will not deny anywhere, but for high-quality insulation of the house there is no cheap wool in rolls, and the mineral wool plates will be needed, the cost of which exceeds the price of the thick polystyrene foam. In addition, the mineral wool is significantly inferior to the foam of thermal conductivity, vapor permeability and other operational characteristics.

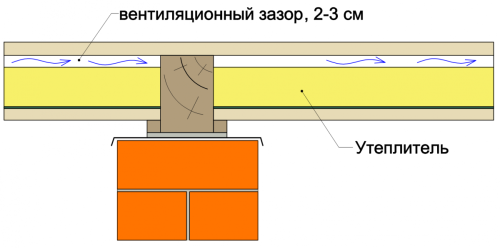

- The house insulated with polystyrene foam, "does not breathe" - first of all it is worth clarifying that the term "breathes" is not technical. To figure out how internal wall ventilation works, you should know the features of the movement of steam streams. So, the water vapor, which comes from the indoor room of the house (pairs from the shower, from the kitchen, drying linen, etc.) passes through the walls, the roof and faces first not with the insulation, but with a vapor insulation membrane (if there is such) . It does not give moisture to penetrate further into the trim and soil the thermal insulation layer. If a small ventilation gap between finishing and vapor barrier is provided in the walls and roofs, then condensate that will be collected on the membrane, evaporates quickly. If not, then the walls, regardless of the material used, will be mowed, so the assumption that the insulation of the house is expanded by polystyrene foam outside does not allow the walls to breathe, simply meaningless.

More information about vapor insulation you can get from articles "Parosolation of the roof: step-by-step instruction" and "Parosolation of a wooden house: step-by-step instruction".

- Insulated polystyrene foam facade does not allow heat to penetrate the house. Yes, it is so, but at the same time, it does not miss the cold air and retains 30% more heat indoors compared to the lack of insulation. If you do not inspire the facade, then you will simply be shattered at your own expense.

- The polystyrene foam is easily flammable and supports burning. The polystyrene foam, in fact, may suffer from fire, because in its composition there are chemical additives, but provided that the proper installation and fulfillment of all the technical prescriptions of the ignition will simply not happen. This material can not be insulated fireplaces and chimneys, walls of a bath or boiler room. Polystyrene foam lights up at + 490 ° C, which is 2 times higher than paper and wood ignition temperature. At the same time, during the combustion, it highlights 5-6 times less energy than the tree, so during a fire the house will most affect the tanned cabinet or a wooden plating than from the insulation.

- The polystyrene foam is very short. As the technology of manufacturing expanded polystyrene was invented not so long ago, in the mid-50s, the question of his durability is rather controversial. However, the conclusion of research confirmed that polystyrene foam plates are able to withstand cyclic tests in an unfavorable medium up to 80 years. The only factors capable of accelerating the destruction of the material are ultraviolet and mechanical effects, so polystyrene foam should be placed under the trim.

- Polystyetilol is dangerous for ecology and health. This statement is deprived of any meaning, to recall at least packaging for food from foam. This material is used for many years as an insulator, to create packages, including in direct contact with food products. It has no toxic substances in its composition, and even during the production of workers do not use any respirators or gloves. The story did not record a single case of a professional illness associated with work with expanded polystyrene. The only nuance is that smoke from the melting polystyrene foam can harm the respiratory system, so the fire safety equipment must be observed.

- The insulation of the facade of polystyrene foam is expensive and unprofitable. On the one hand, this statement is correct - to insulate the polystyrene foam is quite expensive, but this event will pay off in the first few years. It is proved that the insulation of the walls of the house outside, that is, the facade is more correct from the point of view of the conservation of heat. In the first winter, after insulation, you can see the difference in paying for electricity bills.

In addition, polystyrene foam outside helps strengthen and level the walls, so if you want to do not only warm, but also a beautiful house, its use is quite justified. The trim of the facade of polystyrene foam plates will pay off in the first 3-5 years depending on the size of the house and the electricity consumed. - It is not necessary to stucco after reinforcing - you can immediately paint. The task of plaster consists not only in creating a beautiful smooth coating, but also protection of reinforcement from environmental impacts. The paint is sooner or later can be crowned or crap from the frost, after which the moisture will quickly get to the reinforcement, and she will start rust.

- Polyfoam he and in Africa foam - there is an opinion that there is no difference, which polystyrene foam to warm the walls, but it is precisely this error that gives rise to most of the myths about the material. So, when buying, pay attention to the manufacturer - it should be a large plant with a good reputation. The insulation should not be fabulously expensive - you can find a decent option for an acceptable price. Purchase plates and adhesive composition of one manufacturer. The product must be certified.

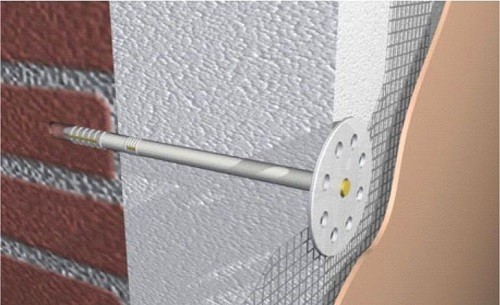

- Insulation on Cheap - Recently, cases of unscrupulous insulation of facades of polystyrene foam plates have become more frequent. Workers, using the ignorance of customers, glue the insulation to the compositions for the tile and do not use mixtures specifically designed for polystyrene foam. Special glue is much more expensive, but unlike tile, not falling off in a couple of months. As a result of such poor-quality installation, the plates are held only at the expense of dowels and "umbrellas". By the way, on the "umbrellas" workers can also save. According to the rules per 1 square. M insulation must be 5-6 "umbrellas", but not 2-3 pieces, as they do in many cases. Unfair "facaders" are significantly saved in such works, and the life of the walls is reduced by 7-10 times, which is why the myths about polystyrene foaming are born ...

Wall insulation

Despite the fact that the polystyrene foam invented more than half a century ago, the walls began to insulate the walls relatively recently. Today, it is used by almost every housing construction or reconstruction of various buildings, and it is used not only for the insulation of facades and walls from the inside, but also to create roofing pie and floors.

The insulation of the walls of the house was preferably carried out outside, because in this case a more complete protection of the house is ensured. However, sometimes it is impossible to do it technically, and it is necessary to work from the inside. Consider both insulation options.

Wall insulation Outside

You can warm the facade with polystyrene foam, both at the construction stage of the walls and after the construction of the house. The main advantage of outdoor insulation is that the walls are thickened outside, in no way affecting the useful space inside the house, which cannot be said about insulation expanded polystyrene from the inside.

Important information: Warm facade is needed by plates with a thickness of about 10 cm (more than). If you have thin slabs, lay them in 2 layers. Otherwise, the sense of such thermal insulation will be a bit.

Before proceeding with the thermal insulation of the house, you need to prepare walls. Preparation lies in stripping and leveling of the surface, after which the sheets of polystyrene can already be glued. For fixation, in addition to the adhesive composition, use dowels and umbrellas.

Useful advice: For the highest quality result, lay the polystyrene foam plates without gaps, but do not allow glue to fillets the joints of the joints. Before applying the adhesive composition, it is recommended to go through the surface of the smooth slab sandpaper - roughness to increase adhesion of glue and plates.

Technology insulation expanded polystyrene

- Print sheets starting from below and moving up. So they will not crawl down while drying the adhesive mixture.

- Small shifts are allowed to 10 cm.

- For additional fixation every 30 cm, install the base profile, the width of which can be equal to the thickness of the polystyrene or exceed it into several mm.

- Follow the socket profile tightly lay down to the wall. Use lining washers for this.

- In the process of docking the end of the profile, leave the gap between the connecting elements from 2 mm.

- For angles, use a special corner base profile.

- When the sheets are securely fixed, apply adhesive mastic and install a thin reinforcing grid, slightly drowned it in the wall. Before buying fittings, specify whether it is intended for external work, since other grids may not have the necessary stiffness.

- On top of the reinforcing grid, apply the second layer of leveling mastic.

- After drying the mastic, treat the wall by primer and proceed to the finishing of the facade.

Important: Warning for the installation of thermal insulation must be carried out in a dry day with air temperature not lower + 5c.

Wall insulation from within

If you insulate the walls of the house outside it is not possible, the installation of expanded polystyrene is from the inside. This is mainly related to the reconstruction of buildings that have cultural value or if the facade finish was fully implemented.

For insulation of the house, thin plates are used inside inside - up to 4 cm thick. This is explained by the fact that the internal space by increasing the thickness of the walls becomes less. Before laying the wall, it is also recommended to clean and align.

For the inner insulation of the walls, it is not necessary to use additional fastening with dowels and "mushrooms".

Useful advice: If the wall outside the house is not insulated, be sure to leave the gap between the facing of the walls and the insulation to organize the ventilation space (about how vaporizolation of the walls and the roofs are already told). The dimensions of this space are individually determined, since its presence involves a substantial thickening of the walls and the reduction of the useful space of the rooms.

After laying polystyrene foam slabs, it is always carried out an finishing finish on the crate. The doom can be wooden or made of metal profiles if you are going to sow plasterboard walls.

Errors when insulation

Warming with polystyrene foam with her own hands recently is the most common way. And it is not surprising - the installation is quite simple, fast, and does not require special professional skills or special techniques. But in most cases, novice masters allow a number of errors when laying, which are subsequently poured into fatal problems.

Common errors when installing insulation:

- It is very important to consolidate the base rack qualitatively. Many fixes only its ends, as a result of which it deforms from high temperature, strifted and provokes the occurrence of cracks on the plaster. To prevent it out, cut the bottom edge of polystyrene foam so as to get to the base rail and create another point of fastening. Over the cutting portion, run 10 cm of plasters, stick the polystyrene foam and attach the reinforcing mesh on the old one by 10 cm. After that, you can apply the finish plaster.

- If you used the rail guide, do not convert the reinforcing grid to it, and cut it at the level of the lower end of the rail. Since the plug of metal and plaster is very low, the plaster will very quickly fall off.

- If there is no base rail, expanded polystyrene foam will be in contact with the soil. As a result, the material will be constantly worst and exposed to mechanical effects, which will lead to it. If the thermal insulation layer must be left in the base zone, cut out the bottom belt of the plates and put the extruded polystyrene foam instead. It is much harder than usual, practically does not let moisture and has a low thermal conductivity coefficient. The reinforcing grid must be wrapped under the sheets of the insulation.

- You can not attach the base rail, but in this case, it is necessary to properly cut the plates of polystyrene, so that the rainwater from the walls does not register.

- Attach polystyrene foam only on an even and reliable base. If the plaster at home crepts, it must be knocked down or enhanced by a layer of primer. The same applies to the raw walls - they need to dry and eliminate the reason for wetting.

- Before fixing the base rail, mark the level and height of the place where the base will border the insulation. The rail width should exceed 5 cm polystyrene thickness.

Finally, the video of the insulation of houses is polystyrene:

Start a discussion ...

Start a discussion ...