Services in the insulation of walls of houses from year to year are becoming increasingly popular due to the ever-growing prices for gas and electricity. Economical hosts are trying in all possible ways to reduce utility costs, and the insulation of the facade makes it possible to reduce heat loss. Of course, this indicator depends on the insulation itself and the material from which the walls are made. One of the most popular thermal insulation materials for the walls is a foam. This article has everything you need to know about the insulation of the facade of the house with foam.

Features of insulation foam

The insulation of the facade allows to reduce heat exchange between the premises and the street to a minimum, and how much will this minimum depends on the type of insulation and the method of its laying. Polyfoam has always been considered one of the most convenient and affordable thermal insulation materials. Its main competitor - mineral wool - also stands inexpensively, but does not possess the operational advantages that the foam.

Positive foam characteristics:

- low thermal conductivity (well kepts the temperature in the room - winter houses warm, in summer - cool);

- does not absorb moisture (protects the material of walls from the blotch);

- vapor!

- it is not subject to rotting, damage insects insect parasites and rodents (information that mice is like to start the foam in the foam);

- low weight (no excessive load on the walls and foundation;

- the insulated surface does not need alignment (you can immediately go to finishing works);

- polyfoam is not deformed over time;

- low cost;

- the service life may vary from 10 to 25 years, depending on the quality of the material and its laying;

- the insulation of facades by foam does not require professional skills.

The only drawback that overshadows this rainbow picture is a foam flange. However, this can be corrected, causing an anti-infrete substance on a warmed surface. If you insulate the walls from the inside, close the foam of plasterboard sheets and do not install the heating devices nearby.

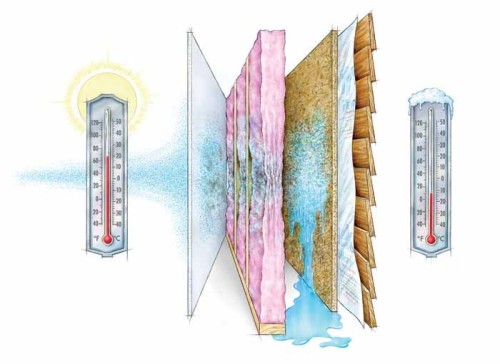

The quality insulation of the walls significantly reduces the cost of heating in private houses, the heat longer holds inside, and you are less likely to include heaters or throw a new firewood batch. There are two ways of insulation of walls - outside and from the inside. All experts strongly recommend carrying out thermal insulation work from the outside of the walls of the house. Only in this case can exclude the freezing of the walls and the preservation of heat.

What happens if you insulate the walls only from the inside? The wall remains unprotected and exposed to low temperatures. It freezes, the cold makes every deeper and ultimately stumbled on the thermal insulation material. When a collision of warm and cold air, condensate is inevitably formed, and since it happens inside the wall (behind the insulation), there is no place to go moisture, it cannot evaporate and accumulates. The material of the wall refers and gradually collapses. From the inside it can be unnoticed because everything hides insulation and finishing materials, but the deplorable consequences are inevitable.

In rare cases, still have to resort to insulation from the inside, but this option is considered in the latter order and in the absence of any alternatives. For example, if the house represents architectural or historical value.

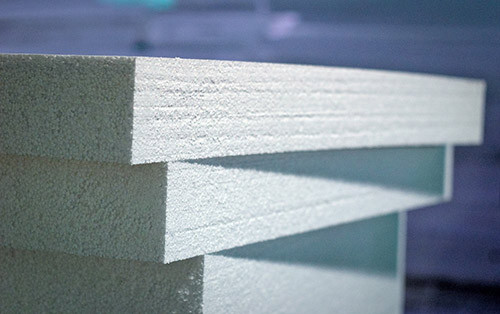

What foam spot to choose?

If you decide to engage in the insulation of the facade of a foam with your own hands, then immediately come across with one difficulty - a wide range of products. There are so many species of foam, products of various density, sizes and thickness. Since you will use a foam as a heater, it should have sufficient thermal conductivity indicators, which is achieved due to a certain sheet thickness and its density.

The density of foam for insulation of the facade should be at least 25 kg / m³. If you take a density product, say, 15 kg / m³, it will not be able to ensure due durability of the facade, and during finishing works you can damage the smooth surface of the insulation. Some for reinsurance buy material with a density of 35 kg / m³, but it is a completely vain spending of money. The cost of insulation of facades by foam of such density is much higher than the products of 25 kg / m³, and the result is absolutely the same.

Before making a purchase, make sure that the product has a quality certificate and complies with European standards.

In addition to foamflast, you will need various mixtures for gluing and processing. Formulations should be designed specifically for working with foam, otherwise the result may be unexpected. When choosing mixtures, you should carefully read the instructions on the package. For example, there is a mixture for sticking foam plates and a separate composition to arrange a protective layer of the insulation, and there is a "two in one" means. Adhesive for foam flag needed depending on the material to which you will be glued insulation: brick, concrete or wooden wall.

Myths about foam

Casual we have already mentioned one false concern associated with the use of foam for insulation, they say, they love to shave the mice. However, this belief is based only on assumptions and has no evidence. In this chapter, we will consider all myths about the foam that should not interfere with you soberly assess the situation and choose the best for your home.

The technology of insulation of facades by foam relative to Nova, and, like every novelty, the foam is immediately "overlooking" wearing rumors, both good and bad. Significant information on the specifics of the insulation of residential buildings did not appear by this material immediately, and therefore many mistakes were made in technology, which provoked the negative wave. The main reason for the appearance of unflattering reviews is precisely the violation of the technology of working with foam, in second place is the wrong choice of material (not the thickness and density), on the third - the choice of unsuitable mixtures.

So, we suggest briefly run through all "foam myths":

- Extruded polystyrene foam is better - there is an opinion that is more dense than foam, extruded expanded polystyrene has the best protective characteristics. However, it turns out that the difference in the thermal conductivity coefficient is only 0.002 units. Along with this, the extruded polystyrene foaming is more than a few times more foaming, deformed due to temperature drops, more weighs, and the adhesive mixtures are more expensive for it (the mixtures for conventional foam plastic are not suitable).

- Mineral wool is cheaper, and the result is the same - the cost of minvati, and the truth is slightly smaller than the price of the insulation of the facades of the foam, but only if we talk about the roller material. For high-quality insulation of the walls of the house outside, it is necessary to use non-rolled minvatu, but products in the stoves, since they are better adapted to the resistance of moisture and subsequent finish. And mineral wool plates are more expensive than foam, we will eat more and less. With excessive wetting, the slab refers and loses its heat-insulating abilities.

- The foam does not give the walls to "breathe" - first of all, it is necessary to realize that the term "walls breathe" is not technical and allows us to designate the fact that the moisture that fell into the pores of the wall may freely evaporate. In fact, everything is as follows: the flows of water vapors that pass through the outer walls of the porous material (brick, concrete, blocks) are 0.5-3% of the total number of vapors derived from the housing by ventilation. Consequently, this negligible percentage is not able to seriously affect the microclimate in the house, and if constant humidity is observed inside, it means the problem in the ventilation system, and not that the "walls do not breathe."

- If you warm the facade, it will not affect the substantial increase in heat inside the house - the insulation of any material is not able to "warm" the house. The task of thermal insulation is to not produce warm air from the house as long as possible, thereby maintaining a comfortable climate and reducing heating costs.

- Polyfoam is fire hazardous - foam and its derivatives, in fact, easily flammable, but when compliance with the installation technology and processing it will never happen. If you put a barbell next to the wall of foam, it will light up, but the same thing happens to the wall of the tree. If you remember the elementary rules of fire safety, you can not worry about fire. To calm you even more, we give a few digits: the ignition temperature of expanded polystyrene is almost + 500c, which is 2 times the temperature of the paper's fire and almost 2 times - wood. At the same time, the burning foam highlights less than heat than a tree, so if it happens, and the fire will arise, the burning wooden server will cause more damage than the insulation, placed outside the wall.

- Polyfoam is short-lived - if the insulation is incorrectly put, it will last long, it is so. However, laboratory studies conducted with the amplitude of temperature effects from + 40C to -40c and humidity drops have shown that the foam is capable of listening to the insulation for multi-layer enclosing structures of about 80 years. If you recall the chemistry course, the plastic is the second most slowly decomposing material after the glass, and the period of destruction depends on the quality of the material. The only thing that can quickly reduce the protective properties of foam on no - direct sunlight. He also cannot resist serious mechanical impacts, but the protective finishing materials help to cope with the facade plaster, siding, facing bricks and panels.

- Polyfoam is toxic - this myth is easily refuted, walking along any supermarket, where most of the meal is in the packages of foam. This material highlights the toxic smoke only during fire, but for this there are aforementioned fire safety rules. In favor of non-toxicity, it is also the fact that it doesn't need to use gloves or respirators to work with foam. Also, in the entire history of working with it, there was not a single disease on professional soil. The foam is characterized by an inert structure, which means its biological neutrality and stability over long years.

- Heat the facade of the foam is too expensive - the question of the high cost is relative. Yes, you will have a rather impressive amount to the materials, but it should be understood that this is a one-time and more than a profitable investment in your own future. The amount will pay off after two or three years, after which you will start saving funds.

- The thicker the foam, the better - if you buy too thick foam sheets, then simply throw money into the wind. Special attention should be paid to the choice of all components of insulation, including sheets themselves, adhesive and protective mixtures reinforcing the grid. When buying a grid, make sure that it is intended for outdoor work.

- And the last myth is in delusion that there is absolutely any unqualified worker to insulate the facade of the foam. The technology, and the truth is quite simple, but there are few people who adheres to, and as a result of the panel fall off in a year, the plaster rushes, the walls are preserved, and the foam is blamed everything. If you hire builders brigade, make sure that they bought the right materials and do not save on it. For example, tiled glue can be perfectly fixed foam plates, and at the same time it costs at times cheaper, but such insulation will last at best six months. If there are special dowel-umbrellas during installation, the material will be held only with their help, but there will be undesirable lumen between it and the wall, where dampness will be gradually accumulated. The unscrupulous builders save not only on the glue, but also on dowels-umbrellas - watch them 5-6 pcs. On 1 m² (often put only 2-3 pcs.). After installing the plates, the facade must cover the walls of primer paint on the basis of quartz sand, and after that it starts to the finish finish. If these conditions have not been followed, the service life of the facade is reduced 10 times, and instead of 20 years, the foam will maintain heat for 2 years.

Warming technology

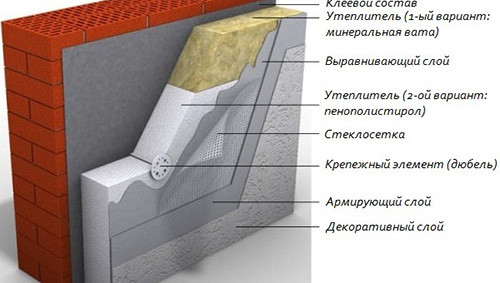

Now that you fully imagine what foam plastic is and what to wait for it, it's time to tell how to contact him. The technology of insulation of the house consists of several stages. In this chapter, we will consider "wet" insulation, which implies the use of plaster to protect the foam insulation.

At the end of the instructions you will find a video about the technology of insulation of facades by foam:

- First, it is necessary to prepare the facade. To do this, clean it from the old solution, finishes, dust and dirt. Treat the base of the milling machine.

- If there are cracks or chips on the wall, close them with putty.

- Apply primer. It is best to use the primer composition of deep penetration, since it better protects the wall from wetting, strengthens it from the inside and creates a good adhesive platform for gluing foam.

- Install the starting profile - a horizontal bar, which will serve as a support for the first row of the insulation sheets. For fixing, use a dowel, installing them in 30 cm increments. Leave the gaps between adjacent starting profiles in 2-3 mm in case of surface movements as a result of temperature expansion (especially relevant for wooden walls).

- Apply the adhesive mixture by one of two ways: if the base is smooth, dispense the glue on the plate with a comb with a spatula; If there are vertical deviations, use lighthouses. On one plate, depending on its size and the degree of irregularities, the base is set from 3 to 6 lighthouses. On the perimeter of the foam sheet, you need to apply glue glue so that an air stopper is not formed inside. The glue should be covered at least 40% of the surface of the sheet.

- Glue the plates to the facade in the horizontal direction from the bottom-up, setting them with the displacement of the seams on half the sheet (in a checkerboard). The first row will rely on the starting bar, so we appline the adhesive mixture on these plates with a small distance from the edge to the installation height of the plank. Constantly monitor that after pressing the plate to the wall between the plates there was no glue - the joints should be clean. Cress the plates as close as possible to each other, and if the slots were formed, block them with trimming of foam or mounting foam. Frames around the windows and doors are better than solid plates, allowing as few junctions as possible.

- After gluing foam plastic, the reinforcement of umbrella dowels. First, drill holes and score a dowel so that its hat is to be flown with the surface of the insulation. Drink or tighten the spacecraft in the plastic part.

- Install the reinforcing elements (plastic or metal corners) at all external corners of the house, on the door and window openings.

- Now it is necessary to reinforce the insulation. To do this, apply a mineral mixture on the wall and pass along it with a furillated spatula. After that, we climb the reinforcing mesh in the mixture for external work, making it from the bottom-up with the adhesive of the mesh cuts of 10 cm. Over apply another layer of mineral mixture and graduate the surface with the rule.

- It remains only to fulfill the finish decorative finish. Naturally, it is possible to start it only after drying the protective reinforcing layer. The decorative coating layer should be the thickness of the fractions of its filler forming the texture. That is, you first need to apply a generous hand plaster, and then carefully dissolve to the thickness of the filler fractions.

- To make the texture of the decorative layer, use a building grater, making it strokes in a circle, in a horizontal or vertical direction (it all depends on the effect you want to receive). In the process of creating a pattern on a grater there will be an excess decorative mixture - do not return them to the general bucket, otherwise they will spoil the fresh composition!

- After drying the textured plaster, it can be painted.

As we promised - video about the insulation of the facade of foam:

Now you can make sure that there is nothing sophisticated in the technology of working with foam no, but there is a lot of nuances that should be remembered if you want to achieve a qualitative result.

Start a discussion ...

Start a discussion ...