When building any housing, a person will be primarily guided by the practicality of the future area, and then his aesthetic appearance. Recently, buildings from environmentally friendly materials with exclusive and luxurious design are firmly entrusted to the leading positions of the construction industry.

To date, urban residents are increasingly striving to acquire country buildings not only for the summer period, but also for winter weekend. A house made of wood at least for temporary rest or intended for permanent residence becomes one of the most affordable in the price category. Modern technology buildings from a bar or logs allow everyone to become the owners of environmentally friendly buildings.

It would seem that quite recently the Scandinavian principles of construction were only in a novelty for our country. European standards for choosing material and buildings from wood were not as developed, and most importantly expensive. However, it is this branch of construction that has been actively developing in recent decades and today, Russian masters fully studied all the subtleties of the construction processes.

The advantages of chopped houses from the log

Among countless positive aspects should be allocated the main advantages of such buildings:

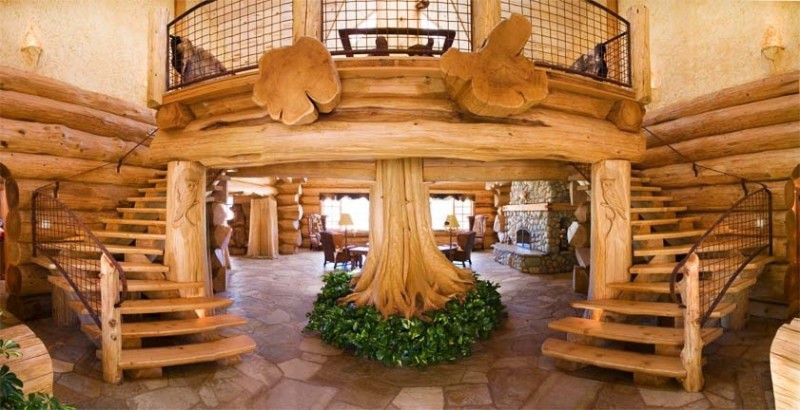

- Absolute design exclusivity. The best solution for those who dream of a unique housing, made by hand, will be the wooden house from a chopped log on a unique project. In addition, genuine wood will never come out of fashion and will always decorate for any interior. Both outside and inside each log will create harmony and attractive comfort and warmth in the house. Manual assembly will add the interior of attractiveness and inhales life in every corner. In such a housing, a feeling of admission to nature and old folk traditions appears.

- Aesthetics of appearance. Back in the ancient times, the masters embodied all the dreams of perfect housing, creating a variety of buildings from natural materials on their own. Today, the quality and purity of the material will be highly valued today allow you to boldly call such houses with elite. In the century of the newest technologies, it is manual to be almost an exotic phenomenon that is truly true to create housing. Built from environmentally friendly wood house, filled with warmth and gives the owner positive emotions every day.

- Energy charge. When building a wooden dwelling, you can independently observe and adjust the process, and sometimes to contribute. Real masterpieces are created solely manually. The house, impregnated with the energy of nature, will fill the tenants to the tenants with new forces and positive mood. The fabulous smell of the forest has long been considered healing and beneficial effect on human health by enriching oxygen with natural phytoncides, wood resins and essential antiseptic oils. The wooden house is considered the standard of modern housing, which every city dreamed of.

- Always healthy climate and environmentally balanced air inside the home provided by the ability of wood materials to "breathing".

- The price policy of both the material and construction and finishing works is available to date, as well as the lack of additional interior decoration.

- High construction speed - on average for the production of every 100 square meters of the area, it takes from 1 to 2 months of work.

- High heat and thermal insulation, as well as moisture resistance, which significantly increases the energy efficiency of the housing.

- Durability of raw materials due to the latest methods of its processing allows you to compare construction wood with brick structures.

Types of chopped houses from a log with a photo

There are several main types of wood, most commonly used to build houses from logs:

- From cedar. The most valuable housing wood, providing not only comfort and comfort, but also a healthy climate in combination with a truly Russian traditional style and aesthetic rich appearance.

- From larch. The uniqueness of home interior and design is created by harmoniously folded into the log house of the crowns and drawing a unique texture of the material through a protective coating.

- From pine. The most convenient and affordable material with smooth, strong, high and without bitch logs that do not require additional processing and maintaining the natural beauty of log cabins with excellent thermal insulation.

Houses of chopped logs by processing method

After selecting the main construction material, it is necessary to determine how exactly the logs will be subjected to processing or "Ostrog":

- Mantha log. Treatment of wood for removing the bark (up to 1-2 mm) without the use of special tools, but using a machine with high pressure water jet for cleaning. The unique technology allows you to use only selected logs without bitch and maintain their identical shape, and wood does not require additional grinding and thus the entire protective (from destruction, pests and infection) resinous layer is preserved.

- Babel or ax. Additional treatment (up to 3 mm) provides for the purification of wood from the orphanage without disturbing the outer surface.

- Tesl. Additional processing implies the process of creating grooves for good docking logs that will be located close to each other.

- Electrolake. Additional processing, during which the entire top layer of wood is removed to 1 cm, which allows you to maintain its main protective function.

- Docylidation. The most affordable mechanical processing (without preserving the protective layer of wood) equipment to give the cylindrical logs with the same diameter along its entire length.

Types of logging Brenen

The main difference of construction technologies and final appearance is to determine the type of wood log cabins. There are two main ways to build wooden buildings - "in the paw" and "into the bowl" or "in the edge". The cutting "in the paw" implies a more complex log laying without protrusion beyond the walls, which significantly saves the material, however, it is suitable for the construction of daches and summer houses or requires additional insulation of the walls.

It is customary to consider the "cup", which implies a log output outside the corners of 20-25 cm and allows you to maintain heat for the houses of the northern regions:

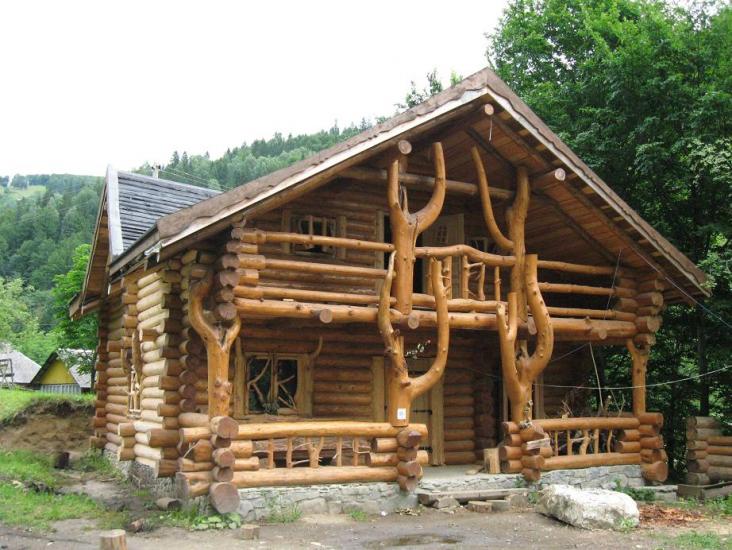

- Wild frame. The most extravagant view using logs that retain the root wood system. The minced houses of this type are calculated on the use of logs of only a large diameter, which gives the construction of an old view, and the unique decor allows you to create individual projects in unique architecture.

- Norwegian or "fauthes" with an angular trapezoidal or rectangular shape of the log section (height 30-35 cm and width 21-24 cm) and perfectly straight walls. The technology involves cutting the logs from the external and inner side of the construction with a thorough selection of material on the diameter for the accuracy of the appearance. Construction comes from logs of adjacent diameters with cut-down burners at the vertical level relative to each other, which are easily jammed when shrinking to maintain heat and dynamics.

- Finnish or "half lights". The technology provides for the construction of a chopped house of the logs of one diameter and their shy only on the inside of the structure.

- Canadian technology with a bowl for jamming in the form of a trapezoid and a longitudinal groove of a round shape size 9-12 cm. When construction is used precisely fitted logs of one diameter (at least 26 cm) without gaps with invisible insulation along the logs on an isolated channel. This method allows you to maintain the unique bends of the material and gives the walls of an individual design.

- Russian technology with a cross-section of a longitudinal bowl of more than 13 cm avoids the occurrence of a crack crack, and its angular release of 30 cm maximally saves heat in the house. The logs when using this method are selected only by a smooth and rounded form.

- Swedish unique technology allows you to create a structure from the hex log logs.

How to build a house from a chopped log?

After the preliminary choice of the processing method and the type of cutting of the main material, you can begin directly the main procedure for building the building. There are several main stages of the construction of chopped houses from a log, the sequence of which is categorically not recommended to violate. Wooden buildings can have an absolutely different appearance after some time, which depends not only on the cost and quality of materials, but also from thorough project development before the construction of the construction process.

Design and construction of the foundation

The creation of an individual project construction depends primarily on topographic and climatic characteristics of the terrain, as it is necessary to take into account all the heat-saving factors of each construction method for a particular territory. Next, determine the method of delivering the material and the place of processing. And, of course, the creation of any project is not accounted for without taking into account the size of the house and the individual characteristics of its design, followed by direct arrangement of the foundation area under the house.

The choice of material and its stripping

The selection of logs should be approached with especially careful attention. Coniferous wood with a dense and smooth inner structure preserves warmth. The logs must be smooth, with a diameter of from 23 to 60 cm and exclude fungal lesions (for checking, you can knock the ax, to hear the clean sound).

Stripping can be performed by mechanically or manually. Such work will cost more, but high-quality wood indicators after shrinkage logs will not decrease. Also, with manual stripping, the material will retain its natural protective layers that will not allow fungus, pests and moisture to penetrate the walls of the house.

Production of a church and frontones

Frams are performed by the selected in advance technique, taking into account the curvature of logs and scigea wood (the whole process takes about 3-4 months). Initially, the logs are chosen, which will serve as the basis or a crown for the walls and the woods of beams for the floor (lags), so they should be the most durable and thick. Over the entire length of the logs, the grooves are cut down (not more than 60% of the diameter) using a special tool (trait) resembling a circulation that will ensure the most dense fit of the material and prevent the appearance of the slots after shrinkage.

It is necessary to follow the direction of the logs to avoid distortion of walls. After the selection of logs, the corresponding markups are made on them, in the corners of which the construction is collected directly on the spot. Fronttonons can be made in several ways - frame-frame with wagon, block house or chilled, which in the assembly process does not imply the use of nails, which will prevent the shrinkage at home.

Processing material antiseptic

Even if the logs for the construction were not cleaned by special technical equipment, the raw material should undergo a mandatory procedure for processing special antiseptic protective equipment from pests and reduced moisture permeability. After performing the lobs on the logs, a protective composition is applied, emphasizing the natural color of the wood. The high-quality antiseptic does not form a visual film on the material and allows it to "breathe".

The basis of any impregnation should include solvent, pigments, biocide additives and a binder. Mineral pigments (iron oxide) are painted wood into the necessary color and protect against atmospheric influences. Biocides (film preservatives) prevent the multiplication of malicious bacteria, and various preservatives are protected from other pests (algicides from mold, fungicides and milduocides from fungi, insecticides from insects).

Installation on the foundation, installation of frontones, roofs and roofs

The final collection of construction (about 2 weeks) is already produced on the foundation for the construction, during which each log house is reinforced immediately tightly. Between the loghouse and the foundation part, it is necessary to sharpen waterproofing materials and insulating jute (moss or pack) and lay the bars to which the main log house will be installed. The logs for the strength of the compound can be sealed.

On top of the design, the frontones are installed, made for chopped or other technologies, requiring additional firmware. After such a primary assembly, a rafting roof system is installed, which is covered by roof, and then all partitions and the installation of attic or veranda, crates and eaves are performed. After laying the draft floor, the construction and finishing of the house must be fully suspended for a period of 6 months to 2 years for drying and shrinkage of fresh wood, in the process of which there is a decrease in the diameter of the logs by 5-10%.

Finishing work

For additional insulation of the walls of the construction of the construction, it is necessary to use the pantry of the slots and connectors that could appear after the uneven drying. Next, you can make the installation of doors, windows and stairs. At the final stage, insulation of the underpants space and overlaps between floors, flooring, and finishing ceiling lifting were performed.

Built house from a chopped log on video

The video lesson will allow you to familiarize yourself with the construction technology directly in action:

Start a discussion ...

Start a discussion ...