Laying vaporizolation during the construction of roofing pie is extremely necessary. Its main appointment is to prevent the formation and accumulation of moisture inside the trim. If this happens, the roof literally can begin to rot and deteriorate from the inside, as a result of which its operational characteristics will come to no. This article is devoted to the installation of vaporizolation of the roof.

Purpose and location of vaporizolation

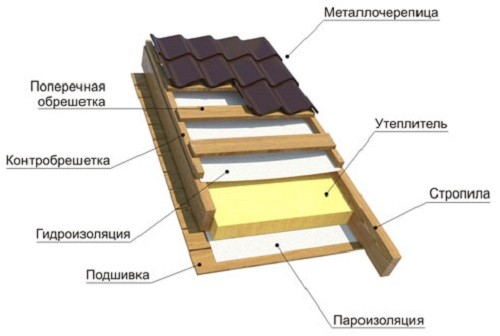

It is known that roofing cake consists of several layers (because it is called). It may include a different amount of sucks, but hydro-, heat and vaporizolation remain unchanged. And if the waterproofing is designed not to give moisture from above to penetrate the house, then vaporizolation does not give evaporation from the inside to get into roofing pie.

It is imperative to place vaporizolation below the heat insulating material, because otherwise it will absorb pairs going down, swell and dance. However, we all know that there are and disappeared roofs, do they really be done without vaporizolation? Unfortunately, no - vaporizolation not only keeps the insulation, but also supports a comfortable microclimate indoor. If it is not, there will be very stuffy and humid in the house, and the cozy accommodation will turn into a regular greenhouse.

To fully assess and understand the roof vapor barrier device, the structure of the roofing cake should be studied:

- Roofing can be solid or consisting of segments (tile, slate). It is placed on a wooden crate or monolithic base.

- Waterproofing layer - protects subsequent layers from moisture penetration outside. It is a waterproof nonwoven material, which is attached to the crate, leaving a small gap between the following layer.

- Insulation - Roofing thermal insulation materials are plates with minimal thermal conductivity. They can be made of extruded mineral or stone wool, foam or polyurethane foam. Depending on the material, the water allowance is different, which also affects the choice of vapor barrier. Polyurethane foam and foam plastic are practically not afraid of moisture, but mineral and stone wool requires the installation of high-quality vaporizolation.

- The vapor insulation layer - films or membranes are installed on the crate immediately after the insulation and leave the gap between the casing ceiling material to provide natural ventilation. When the water vapor, going down, will fall on the membrane, condensate is formed, which will be drained down and dry out due to airing the underpants.

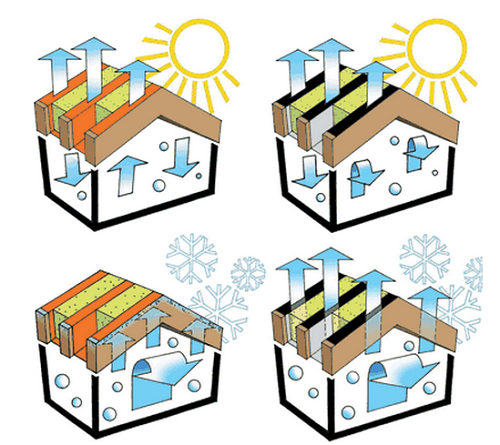

Even the highest quality and modern vaporizolation will not "work", if you do not take care of the ventilation of the roof. Ventilation is important at any time of the year - in winter it will help to maintain heat and prevent the roof icing, and in the summer will give more coolness.

If there is no vaporizolation in the roof of the house, it will inevitably entail the formation of an unrequisite condensate, dampness, mold and fungi. Ultimately, wooden structures and roof elements rot and destroy.

Parosolation materials

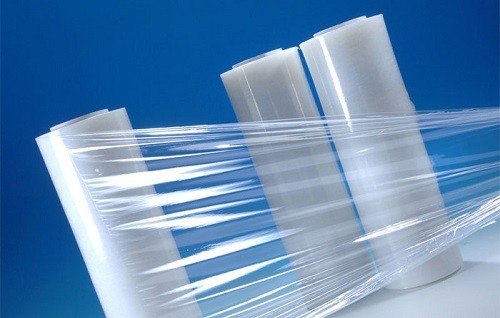

Today in the construction market you can find a mass of underproof materials. Most of these polyethylene-based films. They are waterproofing, vaporizolation and antioxidant. The latter are especially the fact that from the inside side is covered with an adsorbing darous tissue layer, which actively collects condensate, without letting it get to the next layer of roofing pie.

Previously, the main material for vapor insulation was parchment. Today it uses only too economical builders, but if you look at the performance characteristics of pergamine and compare them with the qualities of modern materials, the profitability of the latter will be obvious.

Depending on the physico-technical parameters, three types of vapor insulation films can be distinguished:

- Polyethylene - are used not only for vapor, but also for waterproofing. Distinguish perforated and non-perforated film. In any case, when installing it, it is recommended to reinforce a light mesh or cloth. Perforated films mainly serve to ensure waterproofing, non-perforated - vaporizolation. It would seem strange, because the "breathing" the surface passes water, but the holes in the film are so small that the water simply does not have time to leak through them. They serve for better ventilation of roofing pie. Also, there is also substantial foil polyethylene films, one side of which is capable of reflecting the heat running down (from the house). Therefore, laying such a material follows the mirror side.

Polyethylene vaporizolation comes in rolls. In the process of installation, the cuts of the material glue with each other with special seals and connective adhesive tapes. Thus, it turns out a dense monolithic layer.

- Polypropylene - characterized by higher strength compared to polyethylene films. Used mainly for laying the waterproofing layer, but can serve as vapor barrier. On the one hand, have an antioxidant coating of viscose-cellulose tissue.

- Diffuse - material that appeared just a few years ago. It is a well ventilated membrane that has increased vapor permeability, but does not miss moisture. The main advantage of such a "breathable" vaporizolation is that it does not need to arrange the ventilation gap in the underpants space. Thus, you save space and time.

The diffuse vapor barrier film works very simply - when the pair passes through it, then it settles on the rough layer, absorbed into it and evenly dries, leaving the insulation dry and unharmed. There are single and double-sided films. One-sided can only be laid in a certain way on the insulation, bilateral - as you like.

All film materials used for vapor barrier must have good elasticity, be durable to break and as comfortable as possible in operation. It is extremely important that the vapor barrier film does not rush during fixation, and wrapped the fastener. Even with random mechanical damage to the roof, for example, because of the tree branch dropped during hurricane, vaporizolation must maintain integrity by minimizing the loss. Ideally, the thickness of the paosolation of the roof should be such that the material to withstand the load of heat and waterproofing, if the shapper and the rafter will not hold out.

Parosolation isospan

One of the most popular materials in the domestic market is the vaporizolation of the roof of the Izospan. It is relatively inexpensive, distinguished by impeccable performance characteristics, durability and simplicity of installation. The isospan can be used for waterproofing and as a barrier for a pair simultaneously.

The manufacturer offers several different isospan modifications, each of which is intended for a specific purpose, however, there are universal films. Therefore, it is very important to clarify the characteristics of the selected material before purchasing, so that it is accidentally not to buy an incorrect variation of the isyospan.

Izospan is widely used among professional builders and self-taped hosts. It can be combined with any kind of roofing overlap. In addition to protecting the insulation from moisture, it does not allow microfibers from the cake to turn inside the room, as often happens with other materials.

Installation of vaporizolation

It does not matter whether you make vapor barrier for a flat roof or working with a duplex roof - a film or membrane should be installed only after laying the insulation.

Features of the installation of vaporizolation:

- The canvas can be installed both vertically and horizontally.

- If you prefer horizontal installation, start the installation from above.

- Place cuts of cloths with an overlay no less than 10 cm. Be sure to skip the seams with one-sided or double-sided adhesive tape.

- Choose a wide ribbon at least 10 cm.

- A double-sided tape is glued inside the overlap - first stir it onto the bottom layer, then remove the protective coating and fix the top with the overtrown.

- If you lay the laying of vapor barrier along the rafted without a black insulation binder, make the recess and fixation of the canvas right on the rafters.

- To a wooden crate or rafaling, vaporizolation is fixed with a construction staple or galvanized nails (not rust).

- Cleaning sites are recommended to strengthen the clamping straps. This advice is especially relevant for roofs with a slope of up to 30 degrees and with loose heat insulation.

- At points of the adjoining to the aisles, hatches or mansard windows, the so-called attic apron should be organized through the roof, which is usually included in their complete set. If it is not, stick along the perimeter of the window frame or open 2-sided butyl tape.

- In places passing through the roof of water pipes, wrap the vapor insulation material down, cover the pipe and sealed the tape tightly.

When the vaporizoation is laid, attach the bars over her, treated with antiseptics at a distance of 50 cm from each other. Thus, you will create a air corridor, where condensate will quickly evaporate, and the film will not touch the ceiling. If you use a vaporizolation membrane, install bars optional. But they will be useful to take this space by various communications. If you are planning to finish the indoor room with plasterboard, instead of wooden bars, use a metal galvanized profile.

Errors when installing vaporizolation

Very often, when arranging roofing pie, builders allow errors that lead to fatal consequences. If you confuse the location of the insulating layers, the roof may be unusable after the operation year.

We have prepared a list of the most common mistakes when installing vaporizolation:

- The places of adjoining the film are prisoners are leaning, with the result that the effectiveness of vapor barrier is minimized, the insulation reuses, the rafter structures begin to rot.

- The use of narrow adhesive tape to seal the seams - during the operation of the tape width of 5 cm and less will simply break down. The recommended ribbon width is 10 cm and more.

- There is no deformation supply when working with window openings - any house gives shrinkage, so it is necessary to leave a stock in the form of folds by 20-30 mm.

- The film around the attic windows is not protected by finishing from the inside - if this is not done, after a few months of operation, vaporizolation will be completely unfastened and destroyed under the influence of sunlight.

- The film envelops the rafters - if the vapor insulation material will turn the rafting legs, the moisture will penetrate to the wooden elements, as a result of which they will begin to rot.

- Where vapor barrier is adjacent to the inner walls of the house, mines or chimney, it is necessary to take into account the specificity of the irregularities to which the material will be attached to ensure the tightness of the fixation.

- If you are creating a film to the rough brick wall or surface of non-stroke wood, this will be done only with the help of polyurethane, acrylic glue or synthetic rubber.

- Do not use polyurethane adhesive tapes and butyl rubber tapes, because they are badly kept and can soon turn off the surface.

The penetrating ability of the water steam is extremely high, therefore it is necessary to be extremely responsible to approach the device of vaporizolation. In addition to the popular Isyospan, steam barrier of the roof technonekol is widely used. The most important thing is to correctly choose the materials and install them in the desired sequence, then the roofing pie will serve without repair not one dozen years.

Start a discussion ...

Start a discussion ...