Unfortunately, the wooden house hides in itself many negative sides, which at first glance may be inconspicuous. By themselves, wooden houses can not be called durable, after a few years after the start of operation, there are numerous problems associated with a gradual deterioration in the quality of wood, and here some preventive actions will be ineffective.

If possible, of course, it is worth abandoning wood. Brick and concrete are the most building materials that support the high strength of the structure for decades. However, with a proper approach and wooden housing will last long, but some aspects still need to take care.

In this case, we will talk about the impact of moisture. This is the very power that is capable of not only to destroy the wood, but also create a terrible atmosphere in the dwelling. Thus, it is necessary to take care that wood, under the action of moisture, should not be collapsed.

In this material we will look at the main features of the waterproofing of the wooden floor. We will also try to deal with the main difficulties that occur during the operation of the wooden floor. In addition, we will talk about various tricks that will allow the most efficient waterproofing, and at the same time not to spend too much money.

Varieties of waterproofing

Now there are quite a lot of waterproofing options. Our selection depends on the design of the floor, as well as the appointment of the room.

- Painting waterproofing. A common type of insulation, which is often used in industrial premises on a concrete basis, but such waterproofing can also be used in wooden dwellings. The painting material is a thin layer (1-2 mm) of waterproofing, which consists of polymer varnishes or bitumen. This is an excellent option for those who need a high-quality anti-corrosion material.

- Lata waterproofing. This option is also often applied in cases where it is necessary to ensure waterproofing of concrete surfaces. However, the highest efficiency of this product allows us to apply it on wood. Often cast material consists of asphalt mastics. With proper approach, such waterproofing is almost eternal.

- Plaster waterproofing. This type of coatings are very similar to the usual plaster, but the composition of such products includes various polymers that are easily opposed by moisture. The layer of plaster waterproofing reaches 20 mm, while using this product is not only on the floor, but also on the walls.

- Flew waterproofing. This type of waterproofing is often used for wooden floors. Such products consist of bulk materials that are easily absorbed by moisture. Often, a variety of materials are used to increase efficiency, which are combined in the fight against high humidity. A layer of such waterproofing can reach a half-meter, it all depends on the scale of the room and the specifics of its use.

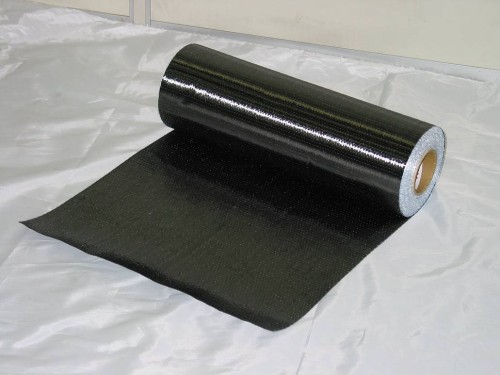

- Equal waterproofing. Also very common products that are often used for waterproofing foundations. In small rooms, it can also be used, especially if there is enough space under wooden floor to accommodate such a "carpet". The material consists of several layers, each of which effectively counteracts the appearance of moisture.

Next, we consider the features of each waterproofing.

Painting waterproofing

This type of waterproofing was greatly popular due to ease of use. In this case, no large-scale work should be carried out to increase the efficiency of the material. It is enough to clean the floor here. This is necessary in order for painting waterproofing well "grabbed". Immediately after drying, you can safely walk on the floor, while the waterproofing layer will not wear out.

Of course, periodically it is worth creating a new layer of waterproofing, but such events should be carried out no more than once every few years.

It is also worth knowing that you can find various options for painting waterproofing. It all depends on the components that are used in products. Using various polymer additives, it is possible to significantly increase the efficiency of isolation, as well as reduce the wear of the created layer.

Of course, this is a good option for waterproofing the wooden floor, but it is not effective enough if it comes to too high humidity in the room.

Lata waterproofing

This type of isolation, as already mentioned, is often used in large industrial premises. Of course, it can also be used for waterproofing of a wooden floor. First of all, it is necessary to understand that the total thickness of the cast layer can reach 25 mm. Accordingly, this will allow you to forget about the incoming moisture. But at the same time it is necessary to understand that this product is quite expensive, and it is not always appropriate to use it in wooden rooms.

It is also necessary to understand that every year the characteristics of cast waterproofing improves. And all because the composition of these products includes revolutionary chemicals that have not been applied earlier in building materials.

Plaster waterproofing

This is another multi-layer coatings that externally resemble the usual finishing material, but in fact we have a perfect other composition. The characteristics of plaster waterproofing allow you to forget about all the problems associated with the negative effects of moisture.

The layer of such a material is up to 2 cm. Very often, the composition of plaster waterproofing includes various polymer compounds, which significantly increases their characteristics.

In construction stores you can find tens of various options for plastering products. This allows you to choose exactly the waterproofing that is as follows to the presented conditions.

Flew waterproofing

As already mentioned, flowing waterproofing is the use of special bulk materials for countering moisture. It is worth saying that often bulk materials are used for floor insulation, but flowing waterproofing also shows good results.

The main disadvantage of this type of waterproofing is too large layer necessary to create a full-fledged moisture protection (up to 50 cm). Thus, such solutions can afford not all owners. Bulk materials themselves inexpensive, so this waterproofing is relatively budget.

Outlet waterproofing

Equal products are the most universal. Despite the fact that this kind of waterproofing is often the most expensive, this is also the most effective option for owners of woody dwellings.

You can find hundreds of various options for this product. Equal waterproofing has a different thickness. For example, if you need to prevent the action of moisture at the foundation level, a thick layer of material will be required. For waterproofing of the wooden floor, thin variations of the inlet product will completely come. However, it is worth learn about all the features of the material in consultants who will provide complete information.

Protection of the foundation from moisture

Very often the reason for the appearance of moisture on the wooden floor is the vulnerability of the foundation. Despite the relative strength and unavailability of the foundation to water sources, such cases cannot be called rarity. First of all, this refers to homes that are located close to rivers or to underground water sources. However, moisture can fall into the dwelling through the foundation that is immersed in wet soil.

In this case, there will also be an excellent option to be inlet waterproofing. It will be necessary to fully isolate the foundation from the possible moisture. It is worth saying that such a decision will be very useful even in cases if the foundation is not a source of moisture. It is that with this scenario, the base of the housing will have almost invulnerable protection from most external factors.

Also used to use the anti-filtration protection of the foundation. In many cases, special systems are created that protect the foundation of the house from the negative effect of groundwater. It is worth noting in advance that the groundwater is a very serious problem that can cause the house that the house is better not worth it. However, if the water source still made itself felt, it should be implemented a whole filtration system that will pass around the perimeter of the structure.

Waterproofing floors on lags

It is not so rarely the situation at which the floor of the dwelling is located almost not the same level with the soil. Of course, such construction solutions should be avoided, however, it is often happening that another way for the construction of a full-fledged building is simply not. In this case, we have peculiar lags located between the main floor and the basis.

Before starting any manipulations associated with the floorproofing of the floor, you need to be sure that the tree lags are completely dry. The same elements need to be treated with antiseptic substances, since in the case of moisture ingress, they will begin rapidly lose their initial properties.

Further, the space between lags can be filled with bulk materials, which said a little earlier. If all empties are carefully filled, then no moisture of the wood floor is not terrible. It is also necessary to make sure that the selected bulk material actually absorbs moisture. You can carry out small experiments that will allow to approximately appreciate the possibilities of natural material. Before filling in the waterproofing material to the surface under lags, a layer of polyethylene can be placed, which protects the wood base of the floor from any sources of water and moisture. In this case, bulk materials will become additional protection.

It will also be necessary to edit the wooden floor itself. To do this, use bitumen varnish. Also, today, you can find a huge number of options for other waterproofing varnishes, which perfectly copble with their tasks.

Specialists also advise the use of primer varnishes. In addition to the fact that they perfectly protect the wood from the influence of moisture, it is also attached to the tree an attractive shade.

It is impossible not to mark various versions. They also have a lot in common with varnishes for wood, and at the same time provide high moisture protection. All such coatings are only an additional protection, and the basic means of waterproofing should be located under the floor surface.

Use of polyethylene film

A little earlier we talked about the fact that it makes sense to use a polyethylene film for additional waterproofing. However, this decision also shows itself well and as the main protection against moisture. More than polyethylene without any problems can hold back large volumes of water than any other waterproofing product can boast.

Often polyethylene films are used for vaporizolation, but in cases where groundwater (or other water sources) is a dangerous threat, it is necessary to use this method.

Polyethylene flooring is made throughout the floor area. It should be borne in mind that the material itself should not have any flaws. In addition, if the product is supplied in rolls, it is necessary to have a mustache. Seams should be sealed with a tape. When any problem areas appear on polyethylene, a complete layer replacement should be performed. It will also be necessary to regularly check the integrity of the material, and if necessary, change it to a new one.

Start a discussion ...

Start a discussion ...