It is difficult to find a person who would not seek to comfort, would not like to automate some household processes. Many seek to do it on their own. For example, one of the modern "amenities" is an automatic gate. Do it yourself at home Open and close with a slight press button on the remote. Most often they are installed at the entrance to the site, in the garage.

It is difficult to find a person who would not seek to comfort, would not like to automate some household processes. Many seek to do it on their own. For example, one of the modern "amenities" is an automatic gate. Do it yourself at home Open and close with a slight press button on the remote. Most often they are installed at the entrance to the site, in the garage.

The most simple ones in their design are swing, they almost do not differ from ordinary, since their main difference, electric drive, is not visible.

Typically, these gates are duplex, opening inside or out. It is worth noting that it is accepted to open them all the same. First, this requires the rules of fire safety, and secondly, it is much more convenient.

Automatic swing gate with their own hands

This type of swing gate has the following components:

a rigid metal frame collected from profile pipes (40x30 and 60x30);

the trim from the professional flooring, wood or sandwich panels (when installing entry to the seams section, sometimes made from forged lattices);

rack made of profile pipe (60x30);

loops;

metal valve.

Getting Started, it should be borne in mind that the automatic gate is attached to the carrier poles, which can be made from the profile pipe with a square cross section (starting with 100x100 mm), a wooden bar, concrete or brick. Regardless of the selection of the pole material, it is mandatory concreted into the ground, at a minimum, at a depth of 1 m.

Consider the installation of carrier pillars on the example of bricks. As a rule, a profile tube (100x100 mm) or a channel is installed in their central part. It welded fittings and then bring out three mortgages, with the help of which the profile pipe is attached to the colls at the height of the gate. The loop is further prior to this pipe. At an altitude of about one meter from the surface of the Earth, the mortgages for drives are also attached to the columns.

The metal design of the gate is collected from the outer base (60x30 mm) and the inner frame (40x30 mm), which is welded to external. It serves to increase rigidity. Metal frame after welding is ground (prepared to painting). Usually automatic garage doors paint alkyd enamel, designed for external work.

The inner frame of the frame is trimmed by a professional flooring, a tree, sandwich panels or similar casing materials that are fixed with self-drawing or rivets.

Automatic gates with their own hands are hung on the loops, which were welded to the racks - profile pipes (60x30 mm). At this stage it is very important to make sure there is no skew of the design. This can be easily done using a level.

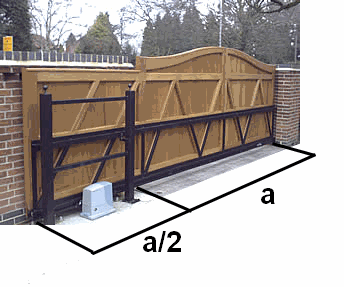

The next stage of installation is the transformation of the usual gates into automatic. The automatic drive is selected, based on the distance between the inner edge of the post and the loop. Possible options:

linear automatic drive (if it is not more than 150 mm) - more modern and aesthetic due to lack of levers;

lever - otherwise (more than 1550 mm).

Automation can only be installed after the final movement of the movement of the sash. Automatic gates with their own hands can be opened with difficulty, and this is unacceptable. It is necessary to find out the reason and eliminate it.

It can be in the skeletal of pillars or frames, low loops. If the drives are not moving in terms of the level, the rod will go to the skew, and the drive will jam.

When installing automation, you need to focus on the installation distances listed in the instructions of the selected model.

Connecting an electrical drive to the network is carried out with an electrical cable - its insulating tubes (from PVC) are paved inside the columns. The automation is connected to the distribution shield by a three-cable cable.

Start a discussion ...

Start a discussion ...