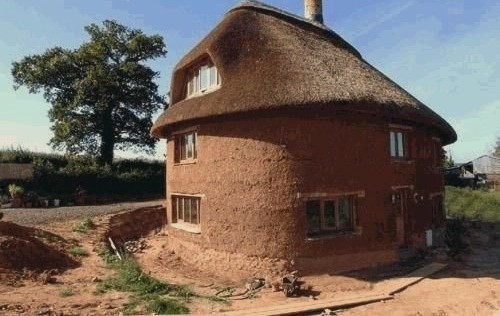

Every year, more and more people around the world are resorted to the eco-building for the construction of cottages and country residential buildings. And most often the main material for construction is clay. Clay houses cost cheaper than similar buildings from modern materials - bricks, gas silicate blocks or concrete. They are warm, cozy, differ in the original appearance. A long time ago, the clay houses were familiar in our latitudes, but the invention of alternative methods of construction and building materials ousted this method. Today you can observe the active revival of the traditions of clay architecture. If you think to join this ancient practice, our article will help you figure out how to build a house from clay.

Why is the clay?

The modern building market offers a wide range of materials for the construction of houses. However, despite a large selection, many prefer proven natural and environmentally friendly options, namely: wood, clay and straw. The main reason for such a decision is often the budget value of construction - clay can be bought for a scentual or at all at all independently free.

The construction of clay houses is the least industrial and at the same time, the safest and easiest way to get your own home. From a long time, people used it as the main building material. And if today, concrete (cement-sandy mixture) is used to create bearing structures and bonding of various elements, then a clay solution was mixed before. Such houses can stand in centuries, especially if they are in latitudes with a moderately dry and warm climate.

I wonder: clay houses were built not only in ancient Russia, but also in Babylon for many hundreds of years before the Nativity of Christ. People took an unconditioned clay, moistened to her and stuffed into wooden rectangular forms, which were then put in the sun for drying. So very durable bricks were obtained, who perfectly retained warm in winter and gave coolness in the summer.

Advantages and disadvantages of clay houses

Before you choose the technology of building your future house from clay, you should identify the advantages and disadvantages of such a building. Immediately we can say that, as in the case of many modern building materials, clay has, rather, not disadvantages, but specific features of operation. That is, in terms of competent use and ensuring due protection, the construction of clay does not have no repair without repairing not one dozen years.

Advantages of clay houses:

- Low cost of construction - clay can be used completely free. The mixture includes sand and straw, which are also inexpensive or get used at all for free. The average price for 1 m gender-based clay housing is only 5 thousand rubles, which is generally incomprehensible with prices for apartments or private possessions.

- Beautiful thermal insulation - clay itself is a good heat insulator, and in combination with straw or other additives, it will not let you freeze even the coldest winter. In addition, the house from clay quickly hangs, the material is well warmed and then gradually gives it warm back into the house, even when the furnace has long been extinct.

- Noise isolation - in the clay house will always be quiet and cozy, even if your site is located near the busy motorway.

- Durability - on average, the clay house will have a minimum of 50 years without major repairs. For longer, such buildings serve in regions with dry and hot climate. So, in Israel and African countries, you can still find houses that have been more than a thousand years. In addition, the rye straw, which is used for construction, do not bite the mouse, and it almost does not rot even during long dampness.

- The speed of installation is the construction of a house from the clay with their own hands does not require a rush, however, its deadlines are significantly shorter than when the house of brick or concrete is erected.

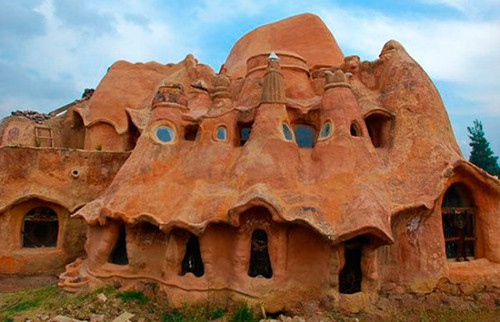

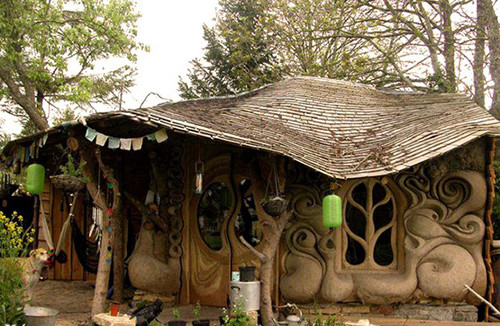

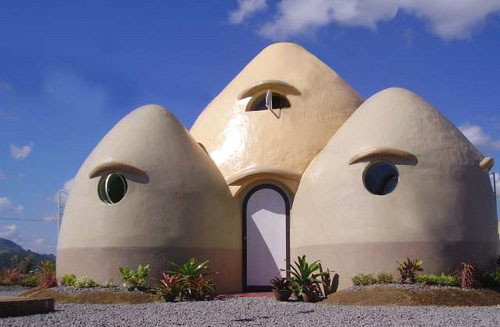

- You can create a unique form design and the same internal layout. In clay houses almost always make rooms with round or smooth angles. It is proved that a favorable and peaceful atmosphere always reigns in such premises without corners, the energy background is better, the tenants are less ill and sad. We can also easily make any redevelopment, having demolished or completing some of the house from the same clay. Remove the clay wall or make a hole in it is much easier than in concrete. To do this, use ordinary electric saw.

- Small weight of the house and foundation gives a small load on the ground, so clay houses can be built even on the slopes. For greater savings, it is recommended to make a pile foundation that can easily withstand the load. Clay houses give shrinkage only in very rare cases, so in the interior can be started immediately after drying the walls and installation of the roof.

- Fireproof - clay does not burn and does not support burning. The same applies to the compressed straw - it does not light up, and slowly smashes with direct contact with fire. For this reason, tenants can immediately clean the smoke and eliminate the source of fire. If the walls are highly shuffled, the clay house becomes non-flammable.

- High seismic resistance.

- Easily lay communication.

Of the disadvantages, or rather, the features of the operation of clay houses can be distinguished by the fact that the walls are required to coating from a rather thick layer of plaster. It should also strictly adhere to the technology of kneading the clay-straw solution and press the blocks well (if you are resorting to block construction). As you can see, there are no fatal complaints here, so it is not surprising that clay houses are so popular today.

Clay and straw house

Most often, clay is mixed with straw. This is a natural material that increases the thermal insulation characteristics of the clay wall. Thanks to the voids in the straw tubes there are small air layers, which serve as a natural barrier for cold. In addition, straw makes the clay building easier.

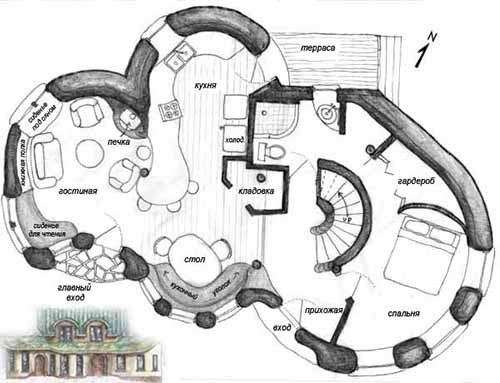

If the proposals for the construction of private houses on modern technologies seem to be unreasonably expensive, we suggest you to take advantage of the invaluable experience of the ancestors and build a cozy home from straw and clay. Start any construction should be on paper. Create a detailed drawing and layout of the future at home. Here you can move away from the usual and boring housing geometry and make the house of any form - the curvilinear facade, oval and round rooms, zigzag corridors. The image below shows an example of a project of a house from clay:

The main points of construction of the house of clay and straw:

- Dimensions of the house must relate to the size of the site on which it will stand. Prepare a platform on the land for the construction. It is very important to ensure good soil drainage. This can be done with an artificial path (sand pillow) or lay the house on the elevation so that the water itself flows down and the foundation does not adversely.

- When the sketch of the house is ready, and there is nothing more to add, calculate the volume of the necessary building materials. For the construction of the house, it will take not only clay and straw, but also crushed stone, sand, tubes for communications (water supply, sewage, gas, electricity), wires, wood for formwork and support beams. If you produce clay on your own right on your site or not far from it, it will be worth learn what additives are needed specifically for this composition. Instead of straw, sometimes folded flax or large wood sawdust.

To make a clay mixture for construction, take 1 part of clay, 2 parts of sand and 0.6 parts of straw or other filler. Since the clay composition is different everywhere (somewhere fatal, somewhere dry), then it is necessary to determine the most optimal ratio of the ingredients of the mixture. To do this, first mix the clay with sand in the proportion of 3: 1, 2: 1, 1: 1, 2: 3, 1: 3 and 1: 2. Add some water to each mixture so that they stick into a lump, but were not too wet. For each lump, make a tag with proportions to not confuse. When they are ready, throw without effort each of them to the ground from a height of about a meter - if the ball crumble, it means that the mixture is too dry, if it turned into a cake - too fat. You will be suitable for the option that has retained the shape during fall - it means the clay is durable and suitable for construction.

- It is possible to knead the clay solution in a piece specifically dug to do this or on a piece of tarpaulin, but it is better to combine these two ways to dig a hole and put it with a hole with a screw at the edges. Mix clay simply - it is necessary to trample its legs until the mixture becomes more smooth. If you have a concrete mixer, everything will be much easier - download the components in it and put an additionally a couple of cobblestones so that they break the lumps and stirred the clay with sand evenly. Soloma in this case is a launder, squeezing from a mixer.

- Playground for construction thoroughly align and remove the fertile layer of soil. The foundation can be made pile or ribbon on the sandy pillow for drainage. The foundation height should be at least 50 cm, and the width (tape) is 25 cm exceeding the wall thickness. You can learn more information on this topic by reading the articles. Ribbon foundation for home with your own hands" and " Fundament Armature Mating Technology».

- Route the necessary communications and drainage pipes.

- The clay-straw mixture will be placed between the wooden walls of the crate. To make this crate, elaborate the wooden frame of the whole house first - with walls, window and doorways, internal partitions. Inside this formwork, start the tamper of the clay with the straw. The wall thickness should be at least 30 cm so that the house is warm and cozy.

- On the perimeter of all walls outside the reed cable. To do this, make mats from the cane, tied by aluminum wire or linen twine. They will provide additional insulation of the walls.

- Cane mats Cover the layer of plaster made of lime and sand in a 1: 1 or 1 ratio. The layer of plaster should be quite thick to securely protect the straw and the reed from dampness - about 25-30 mm. Very beautiful will look at the house in white clay, if such a way to get it.

- From the inside the walls also require shuttering, but for this, use a mixture of clay with sand in a ratio of 1: 3 or 1: 4.

- When the outer plaster is dry, cover the walls of lime paint, collecting limestone dough in 5-6 liters of cold water. Add 0.5 liters of an aqueous solution of the table salt and mix thoroughly. Then bring the mixture to a volume of 10 liters by adding the desired amount of water. So you will get high quality and cheap whitewash. To make the facade unusual, you can add special weather-resistant pigments: mercury cinnabine, ultramarine, purple cobalt, iron suits, umbra, lead chrome green chromium or chromium oxide.

- After that, it is possible to begin the construction of the roof. In more detail we will touch this a little later.

The construction of your own housing is a process that does not require rush, especially if we are talking about a house from clay. The video material below visually demonstrates the main stages of construction:

How to find out if clay is suitable for construction?

If you have a high clay soil area, then it is possible that it is suitable for building a house, and you do not have to buy clay on the side. But not the entire clay is suitable for creating durable and durable buildings. We suggest you to spend a small test to find out whether it is possible to build a house from the ground on its own site.

Useful advice: We recommend digging up a few test holes on the site - very often in small areas there are layers of soils with various composition. The distance between the pit may be from 10 to 20 m.

We test the soil on the suitability:

- Take 3 l of cold water and stir in it 50 g of cook salt.

- Grind several soil samples from different test pits.

- Boil the water by three-liter banks by filling them in half, and put in the sample there.

- Close the banks and shock them strongly for a minute. If clay pieces caught tough, let them splash in the water of 40-60 minutes. And then shake again.

- After such a shake, the samples are divided into small particles. Useful sand will fall in the first seconds. When this happens, make the sand level mark on the bank. Then for 10-20 minutes. It will settle fine sand and il (make a mark after 10 minutes). The clay gradually falls behind them, and the water layer will remain above it. Over the surface will remain swimming organic - pieces of plants, insects, etc.

The precipitate located below the 10-thimy mark is the IL and the sand, above - clay. A layer of useful sand suitable in the first seconds suitable for the construction of the soil is thicker than the clay layer, and the small sand will be quite a bit.

House of clay and firewood

There is another way to build strong and durable clay houses - with the addition of wood or logs. Such a technology is called Cordwood or, in our opinion, Glinocurka. The masonry resembles the creation of a brick wall, but in this case pieces of wood of various diameters and a clay solution are used. The only thing that should be the same is the length of wooden "bricks" corresponding to the thickness of the wall.

The construction of houses from wood and clay was invented relatively recently, but this method quickly gained popularity, since the result justifies the most bold expectations. Separate merit is due to the invention of electric rods - these devices help very quickly cut a large amount of firewood on the segments of equal length and almost the same diameter.

What are good houses and clay houses:

- The cheapness of consumables - firewood is more expensive than straw, however, if you live next to the forest or sawmill, get them not a problem.

- High construction speed - build a house from clay and firewoods can be faster than foam blocks.

- Good thermal insulation - the tree has always been excellent insulating material. In such a house you can organize any heating.

- High strength - perpendicularly located wooden chocks guarantee high stability of walls, even during earthquakes.

- Easy construction - To build your own housing from clay and firewood, you do not need to possess professional skills, it is enough to understand the process and follow the instructions.

- You will not need severe construction equipment.

- The foundation of the house on clay and firewood can be made from inexpensive materials. The pile, columnar or ribbon (ordinary or finely brewed, if the site is on non-empty soil).

- It is impossible not to note the high aesthetics of such houses - some prefer not to overlap wooden ends log plaster, so they give the facade and interior the original appearance. You can "play" with various diameters of logs and chocks, insert glass bottles of multi-colored glass, make a mosaic and create different compositions.

Unfortunately, there are more disadvantages in such structures than those with straw. So, fire safety in the case of firewood is much higher. The tree is burning, even if it is imagined into the clay wall. Therefore, to protect the house, it is better to cover the walls with plaster and strictly observe the rules of fire safety. Additionally, it is possible to impregnate firewood with antipiren.

Disadvantages of the clay house on firewood:

- Since the firewood in the walls are perpendicular, and their ends protrude outwards, the wood is more exposed to moisture. For protection, high-quality paints and varnishes or plaster are used. In the second case, the walls of the house will usually look and lose their uniqueness.

- Such a house is difficult to protect against the pests-edges. For this, in obligatory, all firewood before the start of construction is impregnated with antiseptic compositions and pest poisons.

- Under the influence of the Sun, unprotected ends will quickly sit down and can crack. You can protect them only by plaster. If you leave them prominent and covered with varnish, then update the protective layer will have every year.

The benefits of this method still much more, but there are quite serious shortcomings, therefore it is worth thinking three times before it is decided to build a house from clay and logs. If you are confident in your choice, we suggest you familiarize yourself with the technology of construction.

But first several useful tips:

- Use only a dry forest for construction, otherwise firewood crackle.

- The house of solid logs is rapidly rapidly than, which is from the blue, however, the solution is needed less for them, since they are able to fit them more precisely than the decks.

- Be sure to remove the entire bark from the wooden elements, otherwise it will begin to rot, and it is precisely the pests in it often.

- To make a house as warm as possible, use a deck with a length of 35-40 cm or more.

- Apply a clay solution only around the edges, leaving the inner space empty - it will later be filled with chips, sawdust or straw and will be better protected from cold.

- It will be very practical to hide the facade of the board, and the inner walls are left as it is - with the logs sticking ends. Then the appearance of the house will maintain beauty for long years, and inside there will be an interesting interior.

- For subsequent facade plaster, use a panel masonry. Make a shield from plywood or boards and set strictly vertically outside the wall. Firewood Site on the solution of ourselves to this shield, and a day later, stop it slightly higher and continue the masonry. So you will have a perfectly smooth surface for plaster.

- Take care of the high-quality waterproofing of the foundation and the ground floor.

- The house on firewood and clay weighs quite a lot, so do not save on the foundation. In fact, its weight can be compared with the weight of a brick building.

- Special attention to delivering the corners 0. Lay the bars with a specific step, as shown in the image below:

Construction technology

The house of firewood and clay can be built even without professional skills. The main thing is to properly develop the project and clearly follow technology.

The volume of the clay solution is about 20% of the total volume of wooden saues or decks. To increase the strength, elasticity and thermal insulation characteristics of clay, mix it with straw (10-15% of the total). The foundation for such a house is needed durable, but with a depth of embedding no more than 1 m. The optimal option is 50 cm.

Useful advice: So that the walls of the house are warmer, lay the logs with a minimal thick layer thickness. Place the solution is not a solid layer, but in two parallel lines, begetted with a straw or sawdust.

Consider the construction of a clay house on firewood on the example of a 9x9 m area of \u200b\u200bthe building:

- Length to work will be used 40 cm long.

- Wall lay out as a field, on the corners, each row goes into the twist with the next adjacent wall.

- After 50-70 cm masonry make a strapping from the board of an inch thickness. It is needed for pivoting.

- At one time you can lay out three rows of firewood, then leave the wall to dry for a day.

- To create a smooth outdoor layer, it is better to lender the panel mobile formwork, which is then moving as masonry progress. The same can be done from the inside of the wall.

- To create window and doorways, it is necessary to put the boxes of the same width as the wall thickness. The box should be set on the placement at the place.

- The inner partition can be made on a frame of a bar of 150x150 mm, the ends of which are embedded in the outer walls.

- If the house is another floor joists by one party should be based on the framework of the internal walls, and the second - on the outer wall. Under the beam on the wall lay a board full length of the wall, controlling the horizontal level of the building.

These are the basic principles of building a house made of mud and wood. As you can see, this is no big deal and easy to understand the process, we can guarantee a successful outcome.

Roof clay houses

As we promised, we will tell a little about the specifics of the construction of the roof to a clay house. First of all, it should be given much of the wall, forming a canopy to protect the clay masonry from moisture during rain and snow. Glinosolomennaya roof is fairly simple to make, but differs impressive weight, so it should be done with a slope of 40 ° -50 °. It will last as much, as much as 25-30 years without major repairs. Rarely a cheap building material can boast of such durability.

Features of roofing:

- Rafter system for glinosolomennoy roof should consist of massive wooden beams.

- On the boards of the planks to fill lath thickness of 5-7 cm. These boards have to rely on pins made from hardwood and inserted into the rafter hole diameter of 2 cm and a depth of 6 cm.

- Attach board batten nailed on both ends.

- To protect from the rafters sagging, cast them props. Remove them only after the clay to dry completely and become a little easier. Under the eaves, too, it is recommended to put a support board and prop her a pole.

- Keep the solution for straw contained no impurities and extraneous grass rot. Clay for the roof to be oily and contain no more than 15% sand. It is better to prepare it in advance for the winter.

- Consumption of clay is about 1 m³na 30m² roof. If clay lie down and have a good winter chilled, it will be more friable and easily razmoknet Mixing solution.

- Tie loosely snopiki straw or ocheret diameter of 15-20 cm and a length of 50-100 cm (spikelets chop off).

- Loosening pour the clay into the pit for kneading mortar or concrete mixer, fill water in the ratio 1: 2 and incubate 5-6 hours there was then mix until uniform.. To check the density of clay, insert a straw into it - if it stands vertically, and from it the solution does not flow, the mixture has reached the desired consistency.

- Make the first row of roofs from sheafs with smooth edges, pressing them to a stubborn board. Lay the sheaf on the crate, unleash it and scatter.

- To the first brand, a slightly brass attach another and so on. When you put a whole series, check that its thickness everywhere is the same and amounted to 10-15 cm.

- Starting from the sink, attach shens with rows, gradually moving to the skate.

- At the same time, lay the straw at once on both skate (if the bartal roof), laying 1-2 rows first on one, and then on the other scap. So you can evenly distribute the load on the rafyled.

- When 3-4 rows are ready, dispel the straw metal robers and pour from the clay from above.

- Send a solution with a shovel until the roof is perfectly smooth. It is very important that there are no depressions in the slopes, otherwise rainwater will accumulate there.

Environmentally friendly house built according to the above technologies, not only safe, but also useful for living. Clay and other natural materials have a positive energy background that are favorable to the mental and physical health of residents. To acquire the house of his dreams, if desired and with minimal investments, absolutely everyone can, and the clay houses are excellent proof.

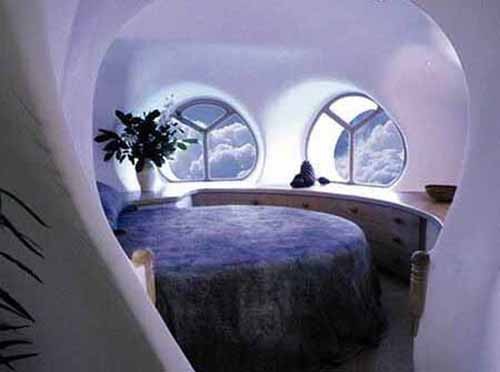

Houses from clay: photo

Finally, we suggest you to see the selection of photos of clay houses, as well as original interiors that can be implemented right during construction. From clay you can make not only walls, but also some interior items and inner decoration. So, a clay staircase, a small table, shelves or niche in a kitchen wall, will look very unusually, where you can add spices or jars with bulk products.

Construction of a clay house is a suitable chance to realize any fantasy into reality and create a unique housing that everyone around will admire! And to begin with, you can make a miniature copy of the house from a polymer clay to then compare the result and know how everything should look like.

Start a discussion ...

Start a discussion ...