Very often, the dacrooms arises the question of how correctly make a stove in the house. I am a professional minister-bricklayer, and today I would like to give some tips on laying the most common type of type

First you need fold the furnace foundation. Heating and cooking furnace for dacket It should be simple in the construction and operation, safe in fire and durable and durable. Equipped with a stove with a hot plate and a brass cabinet, through which a large amount of heat is given to the room, i.e. The front of the furnace has more significant heat transfer than the rest.

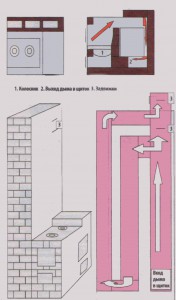

From the oven gases go to the heating shield for additional heating of the room. The shield is laid out in 1/4 bricks for faster heating and heat recoil. For such a furnace, a "low-unique" shield is offered - from 3 to 5 channels. If the pipe has H\u003e 5 m (the height of the pipe is considered from the grate to the tube's head), the shield can be made of 7 channels, which increases its area and, accordingly, heat transfer.

To increase the craving, you should increase the height of the pipe. The thrust sharply decreases if even small cracks are in the masonry or chimney (the reason for unsatisfactory thrust is more likely to defects in the smoke tube, but not fireboxes, as well as the design of the tube barrel).

If the furnace size is 70 × 95 with an altitude of 80 cm, you will need:

• Red brick - 230 pcs.;

• On the shield and pipe - from 450 to 500 pcs. (depends on the height of the pipe);

• Clay - 0.2 cubic meters. m;

• Sand - 0.2 cubic meters. m;

• grate grille -1 pcs;

• Maker 27 × 28 cm -1 pcs.;

• Plate - 1 pc.;

• A truck fit - 2 pcs.;

• brave cabinet 38 × 38 h \\% cm. - 1 pc.;

• Cleaning under the oven - 1 pc.

Undoubtedly fold the furnace with your own hands - It's big art. Nevertheless, it is possible to build a fairly simple and economical oven for the offered drawings, using the difficulties of specialized literature.

Start a discussion ...

Start a discussion ...