Polycarbonate appeared on the construction market relatively recently, but almost immediately began to compete with glass. Excellent light-resistant ability in combination with enviable strength and durability made it worthy of alternative to traditional types of glazing. Sports, partitions and frame extensions from this material are particularly popular. The decision comes by itself when it turns out how much the polycarbonate is glazed - at times cheaper than ordinary glass and even more high-strength double-glazed windows. In this article we will talk about how to make a cozy veranda with polycarbonate glazing.

Product specifications

The popularity of polycarbonate is due not only to low cost, but also exceptional performance. It combines the strength of the plastic and the transparency of the glass, the variety of textures and colors easily allow to enter a polycarbonate design to any exterior. In addition, the material weighs significantly less than the thinnest glass, which means for the construction of it, it does not need a solid foundation and too durable framework. It is easier to care for the polycarbonate than it is enough to succeed with water from the hose or wipe with a rag with an unnormal detergent. It turns out that from such a material will be comfortable bright veranda. Due to high strength, it perfectly replaces even the walls, so the entire design can be built only from translucent panels.

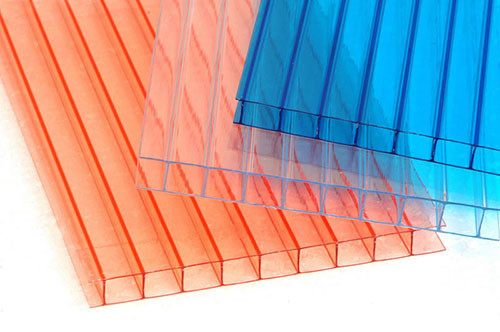

There are two varieties of polycarbonate: monolithic and cellular. The first is a solid panel, more similar to very durable plastic. Unlike cellular, monolithic polycarbonate is distinguished by better light light and higher rigidity with less weight. It is easy to install, safely used, but it is somewhat more expensive.

The cell also has a more complex structure - it consists of two layers separated by transverse grooves (see photo below). According to these grooves, condensate flows as a result of a temperature difference inside and outside the veranda, and is safely displayed. Inside the construction of polycarbonate will always be dry under the condition of competent installation.

The internal grooves of cellular polycarbonate also help keep heat inside the design, creating a small air layer. It also contributes to the strengthening of sound insulation. Choosing material with different density and color, you can create a light or shaded interior of a glazed veranda. At modern cottages and gardens, it is often possible to meet greenhouses from a transparent polycarbonate, and awnings for recreation and visors in front of the entrance to the house are mainly made from darkened (green or blue) material.

When choosing panels for finishing the veranda, you need to take into account the thickness, weight, painting of the material, as well as the manufacturer's reputation and the availability of a certificate. However, the most important characteristic of the cellular polycarbonate is the mass of 1 m², which indicates its density, which means the strength and durability. Often unscrupulous manufacturers deliberately reduce the cost of the panel, sacrificing the mass and making it easier by 10-20% compared with the standard. As a result, there is a deterioration in the performance of the material - it becomes fragile, the elasticity is worse (and elasticity is one of the advantages), can give a crack in the process of fastening. In such "light weights", the inner partitions and the outer walls are significantly thinner than that of a conventional polycarbonate, respectively, they cope with snow and wind loads, and their service life is reduced by 3-4 times.

Buying polycarbonate, make sure that the appropriate marking, indicating the manufacturer, the presence of a protective coating from ultraviolet and the ease of the external panel (helps to perform the installation). When at least small outdoor defects are detected (plugs of small air bubbles inside, scratches, chips, cracks) ask to replace the panel. Also, it is not necessary to acquire the yellowed or clowning material, sheets with impaired geometry.

Separately, you can select the ceiling glazing with polycarbonate. Anyone, even the most small room needs lighting. For the economical owner, the veranda with a polycarbonate translucent roof can be a great reason to save on electricity.

Storage rules

Glaping the veranda at the cottage in the presence of appropriate skills and tools in a few hours, but if you first work with polycarbonate, it can take several days. It is better to work in dry weather, so if it is overcast, you need to fold the panels and wait for suitable conditions. But how to store the material correctly so that it does not deteriorate before the installation?

Long-term storage of polycarbonate requires compliance with a number of conditions:

- It is necessary to protect the surface of the panels from direct sunlight, since the protective coating is only on one side. If you are not treated, and the protective film has been exposed to ultraviolet for a long time, it must be carefully removed, wetting warm water.

- When buying a piece of panels in the store they are usually rolled into a roll, but to keep them in this state is strictly forbidden (in any case not more than a day). Material must deploy and lay on a flat surface in advance cleaned of debris and stones which may scratch list.

- Never stored sheets vertically, otherwise there is a risk of cracking over the entire length.

installation of polycarbonate

From the first minutes of polycarbonate you will appreciate how it is easier to work with compared to glass. However, prior to installation, to prepare all the necessary tools and materials, arranging them close.

What is needed to create a glazed veranda:

- polycarbonate panel;

- wide transparent tape;

- metal connecting profiles for polycarbonate;

- polyurethane foam;

- fasteners (anchor bolts, screws for polycarbonate, mounting screws);

- rubber washers, gaskets fasteners (do not give a scratch panel and provide additional waterproofing);

- drill with drill bits;

- silicone sealant;

- screwdriver / screwdriver;

- a circular saw or bolgarka;

- level, roulette;

- marker for marking.

glazing technology

If you do not have the slightest experience with polycarbonate Be sure to read the instructions, which shall be attached to the material. After mastering the theory, we can proceed to the practical manipulation.

How to glaze the veranda polycarbonate:

- First, we should create a frame or a frame to which is attached polycarbonate. To do this, armed with screwdriver and screw anchors into the frame a few to get something like a direct suspension.

- The sidewall of the frame, screw some screws in the top bar - one screw.

- It turned out that in the upper part of the frame of the anchor a little peek at the inner and outer side of the window.

- Set the profile to the window opening.

- Install the window frame, aligning it with the help of wedges so that it is positioned precisely in the center of the opening. More accurate results can be obtained with the level and roulette. In any case, the frame should be at an angle of 90 °, after which it can firmly fasten the anchor bolts.

- Install the windowsill, if such is provided by the project. Usually, the window sills do not do on the veranda, but if you decide not to deny yourself, pon the panel with the wedges and secure it under the frame. The remaining emptiness between the windowsill and the frame fill in the mounting foam. It will finally secure the panel, prevent leaks and drafts.

- After manipulations with foam, remove the wedges and adjust the windowsill with metal brackets (steel corners).

- Measure the installed frame and transfer these sizes to a sheet of polycarbonate. Collect it in accordance with the labeling with a circular saw, and the edges are treated with a grinder or file so that they are not so sharp.

- Install the segment of polycarbonate in the frame, and the gaps will fill with silicone sealant.

If you want to build a veranda consisting entirely of polycarbonate, read the following chapter.

Construction of the veranda of polycarbonate "From scratch"

Since the veranda itself is not too heavy built, it does not need a powerful expensive foundation for it. And in the case of a polycarbonate frame veranda, it is possible to do completely "low blood." There will be a fairly columnar base, but the choice of foundation should also provide for the nature of the soil (dry, bumping, clay) and climatic conditions. Further information is set forth in the article. "How to calculate the depth of the foundation".

If you make a column foundation, it should be strengthened with strapping or painting. This will allow not only to increase the power of the base, but also create a convenient help for mounting the frame. If you decide to pour a strong ribbon foundation, the reinforcement of dug trenches should be carried out according to frame technology, then install the formwork and pour all concrete. It is possible to install the frame for a concrete foundation only, after pre-using the upper part of the columns / concrete ribbons with waterproofing material.

Build carcass

The draft glazed veranda should be ready long before the start of construction. Polycarbonate is a unique material that allows you to create completely any forms, whether it is a classic rectangle with a single-sided roof or a fancy hemisphere. The frame for such a building can be made of wood or metal profiles.

Associated for assembling the framework is necessary with laying a base of base for the foundation. As we said, at first, the concrete surface should be covered with waterproofing to protect the wooden elements standing above, from refurbishment and rotting. The base ram is better to choose glued, since it is more hardy and durable compared to conventional wood monolith. It should be no less than 150x150 mm.

Useful advice: For a better understanding of the topic, we suggest familiarizing yourself with the article "How to build a frame veranda".

To the base brusade attach vertical racks with a cross section of 120x120 or 150x150 mm. They should be strong because they will hold not only the walls, but also to serve as a support for the roof. Four angular high racks are combined with horizontal bars, raising them to a height of approximately 100 cm from the floor level. Next, the horizontal bars are fastened with thinner vertical racks (intermediate) at a distance of about 50-60 cm from each other. The upper horizontal strapping is separated by the same verticals. The frequency of the installation is depends on the format of the panels installed. Polycarbonate sheets are quite large, but for considerations of strength, it is better to share them into smaller fragments. It remains only to strip the resulting frame with polycarbonate panels, not forgetting to leave a place for the door.

Roof veranda

Make the roof of polycarbonate veranda simplest. Experts are helpful considering its easiest performed among all other roofing structures. Here you need to calculate only the bias of the roof and build a crate. It is easiest to create a one-piece roof of the veranda, the upper part of which is attached to the wall of the house or is a continuation of the main roof.

For the roof, the base of the walls and the upper strapping have already been prepared, so it can be placed on it the elementary rafter system to create the desired slope, attach the crate and fix the polycarbonate panels. The bars of crates must be laid at a distance equal to the ½ sheet width so that the joint of different elements accounted for a bar, and did not hang in the air.

Attach polycarbonate to the crate is very simple - first you need to make marker marker at the points of fasteners, make the hole drill, then fasten the panels with self-draws. Do not forget to put rubber washers between polycarbonate and screws, so that the fastener does not scratch the surface. It is also not necessary to twist, otherwise the polycarbonate can crack. The mounting step is 40-50 cm - for walls, 30-40 cm - for the roof.

A glazed veranda of polycarbonate is completely simple to attach to the house, and not so troublesome. This material is easy to process and install, and at the end of the work there is almost no garbage.

Glazed veranda: photo

Finally, according to the tradition, we bring to your attention a small photo generation of glazed veranda of country houses.

Start a discussion ...

Start a discussion ...