Our distant ancestors always knew exactly what kind of fence to build around their dwellings. And the confirmation of this is numerous archaeological finds - fragments of stone fences. It is this reliable, durable, able to confront the time the material is ideal and for the fencing of modern buildings.

Content

- Stone fence: Advantages and Disadvantages

- Stone fence: varieties of natural materials

- Stone fence: features and varieties of boot

- Stone fence: varieties of artificial stone

- Stages of construction of a fence from natural stone

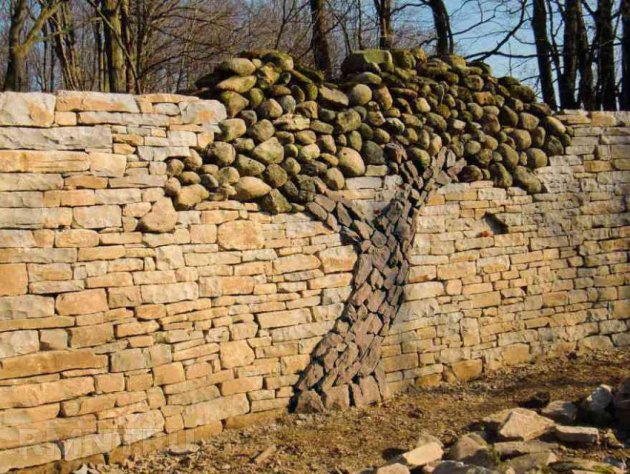

- Natural stone fence: Photo

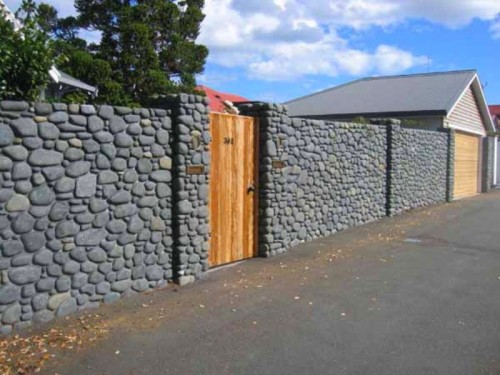

- Fence of artificial stone: photo

- Construction of a slaughter from stone: video

Stone fence: Advantages and Disadvantages

Currently, the construction market offers consumers the widest choice of materials from which the fence of the private house can be built. In order not to be confused in this manifold, first determine for yourself, what kind of materials you give preference. If the choice stopped on the stone, you must understand what is its strengths and weaknesses.

The advantages of a stone for building a fence:

- strength: resistance to the effects of natural phenomena and to physical exposure;

- availability of certain types of stone (for example, cobblestone);

- the ability to combine with stone masonry a variety of materials and create original buildings;

- the stone fence is very beautiful and increases the status of the owner of the house;

- the fencing from the stone will serve for many years;

- fire resistance;

- ecology.

Stone disadvantages for the construction of the fence:

- labor consideration;

- higher financial costs in comparison with other materials;

- the need for foundation.

By taking the final decision to build a capital fence from the stone, you should choose from two types of it. Distinguish:

- fence from natural (natural) stone;

- fence of artificial (decorative) stone.

Stone fence: varieties of natural materials

Natural stone is quite expensive, so it will be worthwhile to ask what rocks are common in your area of \u200b\u200bliving and what properties they possess.

Dolomite. It is mined in careers by explosive work. This explains the appearance of the material - plates of different thickness and sizes. In the future, dolomite is subjected to additional processing and grinding. The undoubted plus of dolomite is that it can be given absolutely any form. When erecting a fence from dolomite, you can choose both arbitrary and geometric masonry.

Granite. It is extracted in the form of blocks and plates. The stone has high strength, durability and high waterproof, has a rich color gamut: black, red-burgundy and white and gray shades. A characteristic graininess of granite texture is attached to the inclusion of various minerals. After processing, it may acquire various textures - from the rough (absorbing light) to polished. It is rarely used in the construction of fences due to very high cost.

Limestone. This breed of organic origin, which consists mainly of calcium carbonate. The stone is durable, high strength, has a homogeneous structure and easy to process. However, its use in construction is limited by climatic conditions: at low temperatures and high humidity, it is quickly destroyed. By structure, limestone is different:

- marblelike (as an intermediate link between limestone and marble);

- dense (possesses a fine-grained structure, there are frost-resistant forms);

- porous - consists of separate limestone spherical grains (the porous limestone, oolithic and pizolithic rocks and some others include porous limestone.

Cobblestone. This is called a natural stone that has a rounded shape. Usually, cobblestones are represented by such rocks as a diorite, quartzite and basalt. This variety of stone is most often used in the construction of fences and fences. The cobblestone is widespread in our country, has natural strength and good workability. It has an affordable cost compared to other natural stones. Its dimensions vary from large potatoes to the size of the watermelon. Larger cobblestones are called boulders.

Galka. It is extremely rarely independently used in the construction of fences due to very small sizes. It is a natural stone of a rounded shape, which is formed under the influence of wind and water. Some kinds of pebbles are produced by crushing and grinding (for example, marble or granite pebbles).

Stone fence: features and varieties of boot

The brownstone (boot) is large, always irregular shape of the debris of mountains or rocks. The length of the edge of the boob stone from 15 to 50 cm. Distinguish Booth in the rock rock (limestone, dolomite, cobblestone, sandstone, less often granite) and in strength (low, medium and high).

On the form of Booth are divided into:

- Flagstone (sawd bout). It is a polygonal tile with a rough surface. Its thickness varies from 1 to 7 cm. The plates with a thickness of up to 2.5 cm are convenient when building a slaughter from a boob stone.

- Putting Booth. Presented mainly by such rocks as limestone and sandstone. Plates have a thickness of more than 7 cm.

- Ripped stone (wild) - is usually a bulk polygonal plate. Due to the rude embossed surface and the richness of the color scheme, the torn stone is often used to build various structures, including fences.

Stone fence: varieties of artificial stone

Artificial (decorative) stone for the construction of the fence is becoming increasingly popular in view of what it is much more affordable for the price than natural. But not everything can be distinguished in the appearance of the natural stone from high-quality decorative.

There are only 3 main types of artificial stone:

- Ceramographic. Its production uses clay and mineral supplements that are subject to pressing under very large pressure with subsequent firing. The finished product most reminiscent of ceramic tiles. It has durability and resistance to temperature drops. External texture varies:

- glossy;

- matte;

- embossed;

- icing.

- Agglomerates. The main component for their production is polyester resin. Various fillers are added to it in the form of stone crumbs: granite, marble, limestone. This kind of artificial stone is used mainly to decorate furniture and interior items.

- Concrete-based artificial stone. In its production, various fillers are used from crumbs, pumice, crumples, painting pigments, etc. It is made by such an artificial stone in two ways:

- the vibrating method (the mixture is poured into the shapes resembling the impression of natural stone, followed by vibration);

- the vibratory method (concrete mixture, filled into shape, is subjected to vibration and a certain pressure).

The basis of concrete-based vibropressing is produced by the so-called french stone. Fence from French stone is easy to manufacture and construction. In essence, the "French" is a wall hollow block. From above it is covered with waterproof materials. Fences from such an artificial stone are rather durable (serve 50 or more) if, with their manufacture, a high-quality solution was used.

Stages of construction of a fence from natural stone

Preparatory stage

- drawing up a plan and estimated estimates;

- determination of the place of construction of the fence;

- marking of construction site (with the help of a peg need to be noted the line of the future fence, as well as gates and wickets);

- purchase of stone and other building materials (taking into account the exact measurements of the future structures).

Bookmark Fundament

Natural stone fences are based only on a belt foundation, which is based on brick or reinforced concrete blocks. It is necessary for the building whose weight is great, it turned out reliable and durable. Stages of the construction of a foundation for a slaughter from stone such:

- dig a trench 35-50 cm wide (wider than the fence 15 cm) and a depth of 70 cm (when the fence is planned height of more than 2 m, the depth is increased in a ratio of 10 cm to 1 m fences);

- determine the location of the supporting pillars (in increments of 2.5-3 m) and to erect them one of the methods described below;

- the bottom of the finished trench to fill gravel or sand (3-5 cm);

- compacted layer;

- bed frame of valves (10-14 mm);

- set of formwork edging boards (approximately every meter backup set, and put on the cross uprights);

- trench fill solution prepared (brands of cement 300, sand and gravel) or brickwork;

- to protect the foundation from moisture set the blind area (a kind of nut with an emphasis on structures). Water flowing down the blind area will not accumulate at the base of the fence;

- foundation must dry for about 2 weeks under the film.

Installing the supporting pillars

Supporting pillars for a fence of stone are no less important part of the building than the foundation: it is they will draw the bulk of the spans. Given the fact that the fence is made of natural stone is a massive structure, it is best to use a concrete supporting columns:

- ready to support plant production;

- aspic supports, which are special forms under fill solution;

- independent production casing for supporting pillars.

Ready supporting columns require significant financial investments. They are installed on the prepared brick base right in the poured concrete.

block support They do not require large expenditures and ease of construction. They come in different sizes, configurations and textures. In addition, in the construction of modular supports convenient to carry cable for lighting or CCTV.

Set of concrete support pillars simple:

- mounted on a foundation reinforcement bars strung hollow blocks;

- pour-prepared cavity by cement mortar;

- ensure that the joints between the blocks does not exceed 11 mm;

- when the solution solidifies - support column is ready.

Self-supporting erect fence poles can also be made of stone in the following manner:

- in the foundation trench filled beakers (concrete cube with a hole in the middle);

- in the middle is set and fixed armature solution;

- on top of the foundation prepared glass set square formwork (height and width 30-40 cm);

- inside the formwork tightly to each other is stacked by a layer of stones (flat face out). If necessary, the shape of stones can be corrected by a hammer;

- stones are poured with cement mortar (1 bucket of cement + 3 buckets of sand + ¼ bucket of glue);

- actions are repeated until the chosen height of the support pillar (they should be higher than the spans by 15-20 cm);

- finished supports are left for drying for 1-2 weeks;

- special caps are installed for decorating and debacing.

Erecting Polyov

The laying of the spans is the most responsible stage in the construction of a slaughter from stone:

- a solution of cement and medium-sized sand is prepared in a ratio of 1: 3 (it must be sufficiently thick and not spread);

- if these are stones with respect to small sizes, the formwork boards are installed between the support pillars;

- if the stones of large sizes, the guide thread is stretched between the colums;

- the foundation is melted;

- stones are stacked symmetrically from two sides of the span, and the voids between them are filled with a solution;

- after laying the first row, it gives a day to dry and harden;

- the laying of stones in the following rows should be necessarily with a dressing (when each top stone rests on 2 or 3 lower, overlapping the seams between the bottom stones);

- for masonry of the last row, the stones need to choose the same in height;

- the top row makes a coating of the plates (70 mm high) or a screed with a concrete solution.

Opening seams

The seams between the masonry are divided into deep and shallow. Deep seams give volume a stone fever. For the seam bout procedure, you must have in stock:

- number (metal strip 150 mm long, 4 mm thick and 2.5 mm wide, which ends with a "dentate" with a height of 20 mm and 10 mm wide);

- triple trimming;

- flat brush from wire.

It follows to break the seams no earlier than 3-4 hours after the masonry until the solution became too tight:

- with the help of a wire brush, a masonry and seams from the excessive fastening solution are cleaned;

- cleaning the grooves of the desired depths are cleaned (there will be a rectangular shape of the grooves);

- the process of laying is completed with the use of foam rubber pieces, brushes and a solution of 30% hydrochloric acid.

The finished fence of the stone is not recommended for dyes or varnish, since it will entail the deterioration of its appearance after 3-5 years.

Start a discussion ...

Start a discussion ...