Today there are a great many building materials for the construction of buildings, however, despite this, many are preferred by brusade houses. Such a dwelling is characterized by high aesthetics, good operational qualities and comparative availability. However, due to the design features of the building, the owners inevitably face the problem of heat losses. On how to make the insulation of the house from the bar outside, consider further.

Content |

Features of insulation buildings

Brous houses have a lot of advantages, including environmental friendliness, ease of installation, design variability. In addition, such buildings quickly touch. However, the durability of the operation of such a building, as a rule, depends on the thermal insulation of the exterior walls of the construction, because Natural wood is subject to corrosion. A detrimental effect also has an intense effect of sun rays, temperature fluctuations and humidity.

Wall insulation outside a wooden house from a bar is preferable to internal insulation, since this approach saves space inside the rooms, as well as protect the facade of the building from the negative impact of the environment. For the effective thermal insulation of the brusade structure, it is necessary to choose high-quality materials that correspond to such a criterion as:

- lack of flammability;

- ease of processing;

- durability of operation;

- safety for human health.

Aspects include the main advantages of insulation of external walls of brusade houses:

- saving a useful area inside the house;

- due to the reduction of thermal conductivity of the facade, heat efficiency increases, which entails a decrease in heating costs;

- design variability and decoration of the facade part of the building;

- protection of walls from the negative impact of atmospheric factors.

Houses from Bruus. Photo:

General recommendations

With the insulation of the walls of this type of construction, it is worth considering a number of requirements that cannot be neglected. Among such aspects it is worth highlighting the following:

- It is strictly forbidden to use raw material, which has not passed the antiseptic processing. Heat insulation such a facade, subsequently, you can face large problems in the form of rotting walls, reproduction of fungus, microorganisms, etc.

- You can approach the insulation of outer surfaces at least 1-1.5 years after the construction of the house. The timber has a property.

- Before mounting the insulation, the wall must be prepared accordingly: eliminate chips, defects, cracking, large slots. To do this, you can use the mounting foam or putty for wood. After that, it is necessary to process surfaces with a special impregnation, which will create a protective layer from the appearance of mold and fire.

Selection of material for thermal insulation

The most common insulation for outdoor insulation of the house from the bar is glass gamble, as well as its derivatives - mineral and eco-wool. This material comes on sale in the form of mats of various sizes or rolls. This allows the use of products as efficiently as possible and economically. The only nuance when working with fiberglass lies in the fact that under the insulation it is necessary to fix a layer of vaporizolation.

Experts categorically do not recommend using for thermal insulation of the walls of the house the following materials:

- extruded polystyrene foam;

- styrofoam.

Such materials have relatively short-term service life, prone deformation and over time, chemicals begin to be distinguished that adversely affect the health of residents.

Outdoor isolation methods

The process of insulation of external walls of this type of construction can be made in several ways:

- by spraying polyurethane foam;

- using the installation of the ventilated facade;

- method of laying foam plates.

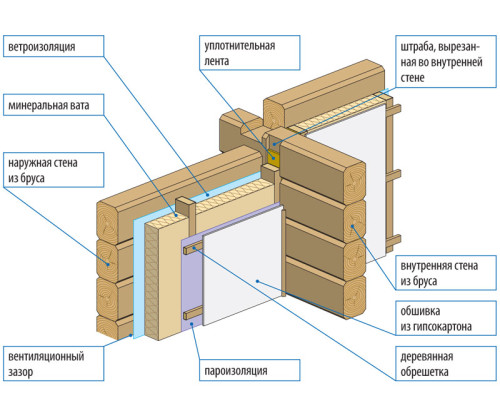

The most popular method is the installation of the hinged facade. This design is quickly mounted, after which it is possible to make decorative cladding from any material (brick, wood, lining, siding, block house, porcelain stoneware, etc.). The hinged facade is distinguished by a high level of noise absorption and heat saving, because The "dew point" is behind the outer wall of the house.

Outdoor insulation home mineral wool

Among the entire diversity of thermal insulation materials, it is glass gambler is an undisputed leader for external work. This material is characterized by environmental friendliness, low flammability, as well as high thermal conductivity - the indicator is 0.036 W / m 2.

Before insulationing the brusade house outside, it is necessary to calculate the required amount of material. It is important to take into account the design features of the walls and the characteristics of the climate of the area. Despite the fact that mineral wool comes in several forms, the most convenient and economical option is the use of plates, 5 cm wide.

So, if the wall thickness of the building is 20 cm, and the lowest possible temperature is -20 ° C, it is necessary to mount the wool in one layer. In cases, if the wall cake thickness of the bar is the same 20 cm, but the temperature is lowered lower than -20 ° C, the insulation in two layers should be laid.

Preparatory stage

To work on the heat insulation of the walls, it will be necessary to prepare the following:

- mineral wool;

- vapor barrier film with a reserve of 10-15% of the walls of the walls;

- metal profile for frame;

- bulgarian;

- antiseptic;

- anchor bolts;

- self-tapping screw;

- small cross section;

- hammer;

- level;

- hacksaw;

- axe;

- construction stapler;

- tassel;

- nails.

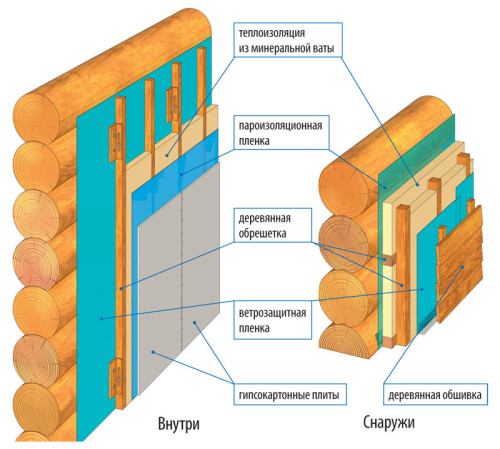

The insulation of the brusade house outside the mineral wool begins with the surface treatment with an antiseptic composition. To do this, use a conventional painting brush or roller. Actions occur in such a sequence:

- The wall must be impregnated several times, after which it is to wait for a complete drying.

- After that, you can proceed to the installation of a vapor barrier film. For this purpose, a construction stapler is used, with which the material strips are targeted by 10-15 cm.

- Then all the joints must be glued with scotch in several layers.

- After that, you can proceed to the installation of the crate. Works should be started from the corner of the house using a metal profile for this. Try to place vertical guides at the same distance from each other, referring to the construction level or plumb.

Installation of insulation

Works on the outer fastening of mineral wool occur in such a sequence:

- The insulation plates are paired in the cavity between the frames of the frame, while the mount must begin from the bottom up. The fixation of the material is made by the versa between the guides of the crates, or with the help of a dowel.

- It is important to ensure that there are no gaps between mineral wool and rails, because This will negatively affect the effectiveness of thermal insulation.

- Acting in such a sequence, solid pieces of material are stacked, and then the remaining fragments are filled with space around windows and doors.

- Then over the mineral wool, another layer of vapor barrier film is stacked. For this, a construction stapler is used, with which the layer is fixed with brackets without tension.

- At the end, it is necessary to fix the material using a dowel with a wide hat, and the places of the films of the film are measled with a metallized scotch.

- On this, the process of thermal insulation of the walls is completed and you can produce the finish finish of the facade.

Eco-insulation

The cellulose insulation called "Equata" is a material, by 81% consisting of a revised fiber of newsprint, by 7% of the bora and 12% of boric acid. These components provide environmental friendliness of raw materials, antiseptic properties and decrease in flammability coefficient.

By its structure, the material resembles the crumbly mass of a dairy or gray shade, which is pressed into briquettes with a density of 110 kg / m 3. Due to this, before applying, the EcoWhat must be poured out of the packaging and dry. As a result of such actions, raw materials increase in the amount of up to 3-4 times.

The advantages of the material are reduced to such aspects:

- resistance to moisture - in contrast to mineral wool, this raw material withstands operation at 20% humidity;

- ecoCata fills all cavities of a frame structure, due to which the risk of "cold bridges" disappears;

- high thermal insulation properties;

- the material supports the natural level of moisture indoors, because is vapor permeable and does not create a "greenhouse effect";

- good sound insulation parameters;

- equata does not burn - the material is tweet;

- such a heater does not allocate toxic evaporation;

- when using the material almost no waste remains.

Disadvantages of the insulation:

- the impossibility of self-installation, without the use of special equipment;

- due to the bulk consistency, EcoWhats are formed with a lot of dust.

Moist mechanical spraying method

In accordance with this method of applying insulation, the action is made in such a sequence:

- First of all, it is necessary to calculate the area of \u200b\u200bthe insulated space, after which you can mount the crate of a metal profile or bar.

- Then in the open wall space between the frames of the frame is sprayed moistened eco-water. A pneumatic sprayer is used for this purpose.

- When the coating completely dry and the layer will become quite plastic, smooth, without deformations it is necessary to remove excess material with a knife.

Humid-adhesive method of application

This technique of spraying the insulation is practically no different from the previous method, with the exception of one nuance. When soaking, the eco-plates together with water are added adhesive components that serve to increase the adhesive properties of eco-water. This approach makes it possible to apply heat-insulating coating on complex surfaces, hanging designs, thin walls.

Thus, we reviewed the basic instructions for choosing the material, the advantages and disadvantages of the main types of insulation, and also led to a step-by-step technique, how to properly insulate the house from the bar outside.

Warming at home from the bar outside. Video:

Start a discussion ...

Start a discussion ...