High-quality and strong foundation is the key to the durability of the whole building. And if the walls or roof can be subsequently replaced, then with the foundation, such a maneuver will not pass, so it is immediately built on the century. There are several types of foundation designs, each of which is suitable for certain types of buildings. For example, a bar base is intended for low-rise non-heavy structures, and the reinforced concrete plate can withstand the weight of the industrial complex. In this article we will tell about how the installation of a powerful reinforced concrete foundation occurs.

Types of reinforced concrete foundations

Among all the types of foundations, only reinforced concrete is distinguished by maximal carrier abilities. It can withstand the weight of a multi-storey house or a whole complex, stands on a very bunching soil and will last for many years. For the arrangement of such a base, high-detailed materials (concrete, stone and bricks) are chosen, which fasten with reinforcement or reinforcing grid.

There are two types of reinforced concrete foundation - prefabricated and monolithic. Let's tell about each of them in more detail.

Prefab Foundation

The prefabricated design consists of separate elements that are ready-made concrete blocks. They are placed as tightly to each other on the belt and fasten with the solution.

The main advantage of the precast concrete foundation is that the installation saves a lot of time, and after a couple of days of work, you can start warming and finishing at home. However, the implementation of such a project will require significant financial costs - the smallest block weighs at least 300 kg, and it is simply impossible to raise it without the help of construction equipment.

The price of bookmarking such a foundation includes not only the rental of equipment, but also the cost of transporting heavy concrete blocks. Because of their weight in one trip, the truck will cope with delivery of 10-12 pieces. As a result, the cost of transportation may amount to 20-30% of total costs, therefore this type of foundation is chosen only in cases where the speed of construction is more important than any financial issues.

For the construction of a country house or a small structure (garage, summer kitchens, etc.), the national foundation will not fit - it is too powerful and expensive. Evaluate reliable and durable housing is much easier on a monolithic basis.

Monolithic w / b foundation

The monolithic reinforced concrete foundation is much cheaper at cost, although its arrangement takes more time. But, as you know, a high-quality construction of a hurry does not like, so many owners prefer exactly this type.

Monolithic foundation has the mass of advantages:

- The low cost of consumables - for filling the foundation, requires cement, crushed stone, sand, fittings and other materials that can be advantageously purchased in the construction market.

- Easy construction - having studied the theoretical part, even the builder-novice will cope with the fill of the foundation.

- It does not require heavy construction equipment (only for the delivery of building materials).

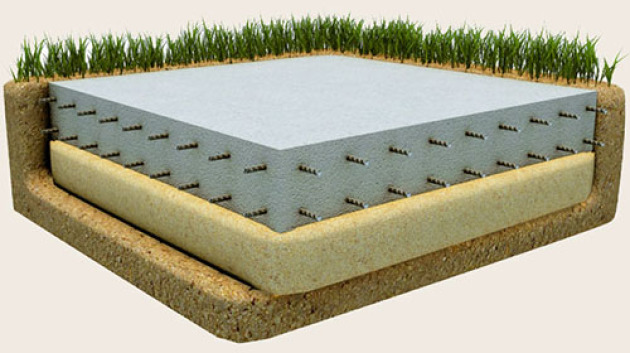

- A large support area evenly distributes the load, as a result of which the high-rise building will be steadily stand even on the weak soil.

- In the walls of the soil, the wall will not be deformed, because the stove transmits them minimum loads. This not only guarantees the prolonged integrity of the walls, regardless of changes in the soil composition, but will also allow redevelopment at any time, without fear that the house falls.

- The powerful monolithic plate holds the walls, is the ideal base for laying insulating materials, itself provides additional heat and waterproofing.

- When arranging a monolithic foundation there is no need to install overlapping plates.

- Since the wide plate has a minimum of the load on the ground, more precisely, it distributes evenly, there is no need to dig deep-cutting. Thus, we avoid contact with groundwater, especially if they run on your site near the surface.

In this case, the monolithic design is much stronger than the national team, where stability directly depends on the quality of block bonding.

Device of the national foundation

If you need to build a reliable and sturdy house as soon as possible, use the foundation assembly technology from blocks. Before you go to the factory for them, it is necessary to calculate the reinforced concrete foundation. If you have never been doing before, it is better to trust this specialist or use an online calculator to learn an approximate number of necessary blocks.

Most often, the precast concrete foundation is chosen for the construction of buildings that will have a basement or ground floor. By the way, with a monolithic basis to make a cool cellar will not work.

So, how is the construction of the national foundation:

- On the territory of the future at home, a fertile layer of soil is removed and make marking - sticking pegs in the corners of future walls, stretch between them the cable.

- Adhering to the created markup, digging the pit with an even bottom across the entire area of \u200b\u200bthe future basement or basement.

- On the perimeter, the sandy mound (pillow) is made on which brought reinforced concrete blocks are installed.

- Blocks are customized to each other as close as possible, and the seams are sealed with cement-sandy solution. In standard blocks, excavations are found in the entire height, designed to fill with a solution of vertical seams.

Useful advice: Specialists recommend drawing the seams of concrete blocks on the same principle how the brickwork is mounted. - Outside, the resulting wall is closed with waterproofing material. It can be liquid bitumen mastic, modern rolled materials or sprayed waterproofing. Recently, penetrating waterproofing is very popular - special liquid compositions that can penetrate inside the concrete wall, to react with concrete and fill out all the smallest pores.

- Next, you can proceed to the construction of walls and rough floors.

As you can see, the process itself is at all simple and rather fast, so if you want to save time, the national foundation is the best option.

During the construction of the national foundation, it should be remembered for the need to create technological holes for engineering communications - electricity, sewage, water supply, gas, etc. To do this, the block is inserted into the block with galvanized steel, plastic or ceramics (you can also use other materials, the main thing is that they do not rust). After installing cases according to the project of the building, they should be temporarily covered with a scenario with a rapid so that the garbage does not get inside. When all communications are laid, the cases are boosted and provide complete tightness.

Device of monolithic foundation

The monolithic w / b foundation is most popular in private construction not only because of its cheapness, but also because it can be made with your own hands without help. If you want to get a solid private house in several floors, we offer to build it on a monolithic base.

The device of the monolithic reinforced concrete foundation consists of several stages:

- Clean the plot from weeds, bushes, garbage, align the surface if necessary.

- Note the boundaries of the location of the future foundation and from all this area to remove the fertile layer of the soil (usually it ranges from 10 to 30 cm).

- Make marking trenches for filling the foundation. So that the base does not shift, you need to immediately install a landmark. For this, over the entire perimeter in the ground, stakes are sticking and stretching between them the cable or a thick bright line.

Useful advice: When you place the width of the trench, be sure to make the allowance of about 20 cm for formwork (10 cm on each side) and drainage pillows. Later, after dismantling formwork, these voids will have to fall asleep with rubble. - Drop the trench, focusing on the fishing knuckles stretched. Digaway will also take a 20 cm allowance to fit the drainage pillow under the concrete foundation. It is necessary for the discharge of extra moisture from the back of the foundation. Otherwise, it will very quickly destroy underground and melting water.

- When the trench is ready, sleep its bottom with granite rubbing, making a layer of 10 cm.

- Failure rubble and pour out the 5-centimeter layer of fine river sand without clay impurities.

- Waving sand with water from the hose with a sprinkler and thoroughly confuse.

- Install the formwork on the inner walls of the trench. You can make it from ordinary raw boards or construction trash. To enhance reinforced concrete foundations, professionals often use a non-removable formwork (after filling the concrete it is not necessary to remove it from the trench).

At this stage it is very important to correctly set the formwork. To do this, every 40-50 cm take a peg on the peg on each side of the trench - horizontal elements will be relying on them. Inside, put on the edge wide boards or moistureproof Phaneru, so that the "corridor" turned out to be a "corridor" with the rammed sandy bottom and smooth walls. - Self of the bottom of the "corridor" with waterproofing material - film, membrane, rubberoid.

- Prepare a classic sandy-cement solution and pour it over the waterproofing, making a layer with a thickness of 15 cm.

- When concrete fully solidifies, you can start laying fittings. Tie reinforcement rods in the frame (bundles are shown in the image below). To fasten the elements among themselves using welding or wire. The welded frame is considered stronger due to the immunity of all parts. But if you failed to get a welding machine, or you do not know how to handle it, you can simply twist the reinforcement with thick sturdy wire. Such a base will also be high quality, and the tighter you twist the rod, the longer the foundation will last you.

- Place the fastened reinforcement frame in the trench.

- Before proceeding to the pouring of concrete, moisten a wooden formwork (if, of course, you do not use a non-removable) special oil solution that can be purchased in a construction store. It will help to easily dismantle the "corridor" and will not give a solution to adhere to the boards.

- Fill the trench for the rest of the rest of the concrete (20-25 cm). At this stage, the main thing is to prevent the formation of air bubbles inside the solution. If they remain, and the concrete will freeze, the foundation will turn out to be fragile. To eliminate emptiness, construction vibrating plates are used, but if it did not turn out, you can simply give a long across the solution with a long across or piece of fittings.

Important moment: Pulling the trench concrete is recommended for one occasion. And if you can still make the desired amount of solution alone, then you have time to pour it to hardening it will not work, so it is worthwhile to enlist the support of relatives or friends. Two or three people will be able to quickly pour the entire solution along the trench. - After filling and eliminating bubbles, close the concrete with a dry cement so that it absorbs excess moisture, cover the film (from precipitation and morning dew) and leave to dry for 3-4 weeks.

Useful advice: Professional builders have found a way to speed up the process of setting the reinforced concrete foundation - they are added to the cement-sandy solution. Special ingredients contributing to the rapid hardened concrete. Usually such additives are used to create ready-made mixtures and in cases where it is necessary to quickly finish the construction before the start of the cold (rainy season).

After 4 weeks, you can proceed to the insulation of the foundation and the construction of the house of the house.

The device of reinforced concrete foundation before the disgrace is simple. But if you remember the expression of one German architect, who claimed that the devil is hidden in detail, it is very important to accurately adhere to technology and know "pitfalls". So, if you make too thin drainage pillow, the concrete will dance, if you do not remove bubbles after the fill - the base can be cracked at the construction of walls or roofs, if you save on the cement brand, all the work can come up at all. In spite of everything, the monolithic foundation today is considered one of the most correct ways to build a strong and inexpensive foundation for the house.

Start a discussion ...

Start a discussion ...