The laying of high-quality foundation is the key to the durability and strength of any building. This will require not only good building materials, but also knowledge of construction technology. And one of the fundamental moments of this technology is the arrangement of a special preparatory platform. In the case of a ribbon and monolithic base, it is absolutely necessary, and in this article we will tell in detail how to make concrete training under the foundation.

Types of preparations for the foundation

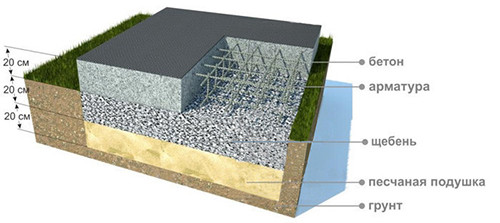

Concrete preparation for the foundation is necessary to equalize the base before the fill of the ribbon or stove. In addition, it does not allow cement milk to absorb into the ground. If this happens, a liquid will leave the concrete solution, the foundation after frozen will be fragile and unable to cope with its destination.

Before starting to build, calculations should be made and engaged in the preparation of the construction site. The preparation itself can be made of concrete, bulk or film materials, but in any case, it must meet certain specifications. According to SNiP, concrete preparation under the foundation is characterized by a regulated thickness depending on the material selected. You can get acquainted with the basic norms in SNIP 52-01, SP 52-101 for 2003 and in SP 50-101 for 2004.

In general terms, the creation of a preparatory platform for the foundation gives these results:

- Protecting the concrete layer from leaks, which will allow the foundation faster to dial the required amount and improve performance.

- Leveling of power influences provoked by primer moving. In other words, concrete preparation evenly distributes the load throughout its area and at the same time weakens the powers of the soil, without giving them to harm the house.

- Providing comfortable conditions for laying a reinforcement frame - to work on a flat surface is much more convenient and faster.

So, concrete preparation for the foundation can be created from skinny concrete, rubbank or profile membranes. Consider the use of these materials.

Playground from concrete

Since the main task of the concrete site under the foundation is to eliminate the possibility of shrinking soil from a large load, the use of a solution of skinny concrete is quite justified. It will provide the basis of good sustainability, create a solid and level surface for work. On the other hand, the use of skinny concrete is not always rational from the financial side, but despite this, this method is the most popular.

Skinny concrete is called the mixture, which contains the content of the cement part does not exceed 6%. Moreover, it takes cement low grades (M100). Fillers for increasing strength serve crushed stone or gravel. The bottom of the skinny concrete is poured the bottom of the dumped pit, and after it is frozen, they begin to mount the reinforcement and the fill of the foundation.

The thickness of concrete training under the foundation may vary depending on the characteristics of the soil, the load on the foundation, the level of groundwater, the area of \u200b\u200bthe future structure, etc. These provisions are written in detail in SNiP. The recommended thickness is 40-100 mm.

The concreting of the pit makes it possible to eliminate the risk of deformation of the reinforcement frame, as well as the walls of the foundation plate (tape). If you are forced to perform work in cold weather, anti-sore additives should be added to the solution of the skinny concrete.

Useful advice: in winter it is easier to make concrete preparation, rather than rubble, because with the simplicable rubble it is almost impossible to work.

Preparation of chief

Crushed stone or gravel preparation is a good alternative, but relevant only in the case of the arrangement of the support-pile paintworks or monolithic foundations. The thickness of the subfolder may vary from 100 to 200 mm depending on the characteristics of the soil, load and other factors.

Often, builders use mixed techniques, falling asleep the bottom of the breadpage, and then watering it with a single concrete layer to 80 mm. Such measures are particularly relevant if the construction of the foundation will be carried out by heavy materials: stones, boot concrete blocks, etc. If the site is located on the brunch of the soil, the thickness of the rubbed layer must be at least 150 mm, and the concrete fill is at least 30 mm. For relatively lightweight materials, such as gas or foam concrete blocks, preparation can be made from sand. To do this, it is poured with a layer of 10-15 cm, they are tamped, mounted formwork and pour the foundation.

Construction standards do not give a clear answer to what kind of preparation is needed in each case. It is only known that for crushed stone preparation, sufficient thickness of the bulk layer is not more than 200 mm. If the foundation of the future house is a monolithic plate or any other base of a similar type, reinforced with frame structures, it is better to make concrete training.

Among other things, it should be borne in mind that rubbed preparation implies the subsequent fill with molten bitumen, which aligns and strengthens the surface, and also creates a reliable waterproofing layer. It is clear that in winter it will take more resources to create such a pillow, so it is better to work with the crushed in the warm season.

Preparation of profile membranes

Profile membranes for working with foundations All as one claim that their products can fully replace any rubble or even concrete training. In some cases it is. The advantage of using membranes is the efficiency and cleanliness of the work - no one with a solution or bulk materials. It is enough to put the membrane on the bottom of the pit and start a bookmark.

How to make concrete training

Despite the possibility of choice, many prefer to trust traditions and make concrete training under the foundation. The price of such an event can be higher, but the result allows not to doubt the durability of the construction. In the skinny foundation, the concentration of cement is very small. It is used not only to improve the foundation preparation, but also for filling the floors. To prepare a solution, it will take the cement brand B15, while for all other construction work it is not suitable - too low.

On 1 bag of cement, about 344 kg of river sand and 10-11 liters of cold water will be required. How to choose the right sand, recommend reading in the article "Sand for foundation: Features of choice and use".

Sequence of work:

- Clean the area from the garbage and remove the top layer of the soil with grass and roots (the thickness of the turf is usually 20-30 cm).

- Make a breakdown of the foundation in accordance with the prepared plan.

- Align the platform for the future foundation.

- Make a crumbling of a thickness of 10-15 cm thick. It will remove the extra moisture from the concrete base.

- Treat the drainage chicken pillow with vibropilet.

- On the perimeter of the working platform, set the formwork from moisture-resistant plywood or boards. Its height will depend on the thickness of the concrete pillow (maximum of 30 mm).

- Prepare the concrete and pour the rubbank to the edges of the formwork.

- Strengthen the pillow with reinforcement mesh or knitted rods (steel rods are required with a diameter of at least 8 mm). The reinforcement will fasten the foundation with the preparation, so the rods must turn over a concrete surface by 20-30 cm.

- Match the concrete vibrating plates to release all air bubbles formed during the fill.

Experts recommend making concrete preparation for a ribbon foundation with a small margin in all directions - literally 10-15 cm. This will strengthen the stability of the foundation and takes off the extra moisture. Such a fill technology can be used for any kind of foundation, but if we are talking about construction from lightweight materials, you can save on materials and perform a lightweight version (sand pillow).

Important: If you decide not to reinforce the foundation pillow, the concrete layer should rise above the ground level by 15-20 cm.

The device of concrete training under the foundation is pretty simple, but this does not mean that without it you can do. If the tape or base plate will be installed directly into the ground, it will lead to the inevitable and very fast destruction of the house. Preparation of rubble and concrete, on the contrary, prolongs the deadlines for many years.

Start a discussion ...

Start a discussion ...