We are accustomed to the fact that the oven gives heat and the ability to cook food. But the brazier, smokehouse, barbecue, the oven - something completely different. However, all these useful devices can be combined in one.

We are accustomed to the fact that the oven gives heat and the ability to cook food. But the brazier, smokehouse, barbecue, the oven - something completely different. However, all these useful devices can be combined in one.

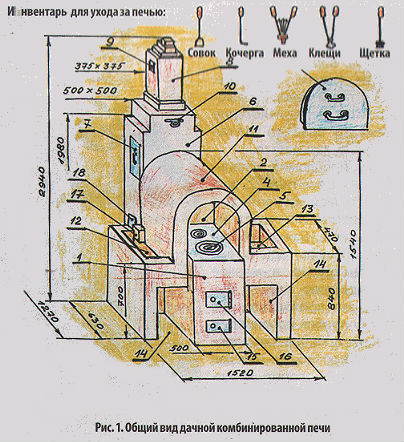

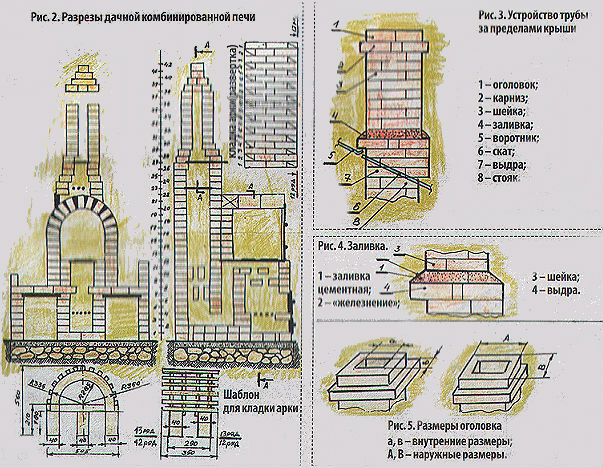

In the country there is a combined country furnace with an unusual on the type of pipe leaving the fireplace for the lip of the roof. I built this oven for outdoor air at the request of my wife. She Tested in work and, as a fireplace, can be made with your own hands. Furnace dimensions 1520x1270x2940 (top of the chimney) mm. Its device is represented in Fig. 1 and 2. The furnace has a cooking double-circuit plate, a nutritional chamber (by the type of rural furnace), a brazier, barbecue and smoking chamber.

_________________________________________________

Materials required for the construction of the furnace:

Materials required for the construction of the furnace:

- Brick red size 250x120x65 mm - 475 pcs.

- 100 bricks mortar:

- clay - 2-2.5 buckets,

- Sand -1.5-2 buckets,

- Salt - 100-200 g,

- Water - Sour cream to delicate.

- Constructive elements:

- plate twokone 710 × 410 mm- 1 pcs,

- Furo door 280 × 280 mm - 1 pc.,

- grille grate 260 × 260 mm - 1 pc.,

- Rold drawer Retractable 250x280x435 mm - 1 pc.,

- Door of the smokehouse 250 × 490 mm - 1 pc.,

- Door clean 140 × 140 mm - 1 pcs.,

- damper of a tomb oven (at place) -1 pcs.,

- Frame Support Mangala 375 × 500 mm - 1 pc.,

- Rama support barbecue 375 × 335 mm - 1 pc.,

- smoke catch 120 × 500 mm- 1 pcs.,

- pins suspended with a diameter of 10 × 270 mm - 3 pcs.

Opportunities:

Preparation of the first and second dishes on a diumphant cooker.

Bakeing bakery products, tomorrow dishes and milk, drying of fruit.

Preparation of kebabs on the built-in grill.

Cooking on a barbecue of various products and vegetables.

Smoking meat products, fish, fruit in the smokehouse.

Drying and storage of firewood in two drying chambers.

Initially, the furnace is dried two to three weeks without intimidation.

Then betented with minor portions of straw, paper, chips. After that, you can heat firewood, briquettes, full loading coal.

Use the hob stove with an open damper. Use the tomb chamber when the covered valve. Maintaining the necessary temperature in a tomil chamber by burning fuel in a separate furnace unit.

The use of the smoke chamber is possible separately or together with other parts of the furnace with the flip of wood used for smoking.

The temperature is maintained in all parts of the assignment of the ash drawer, the valve used by the combustion material and its amount.

Special channels in the fiber space align the temperature of the flue gases according to their effects on the part of the furnace, and the channels in front of the smoke chamber reduce it before entering the chamber itself.

The furnace can be left without additional outdoor processing, whitewashing, plastering, coat with colored solutions, lining with tiles or tiles.

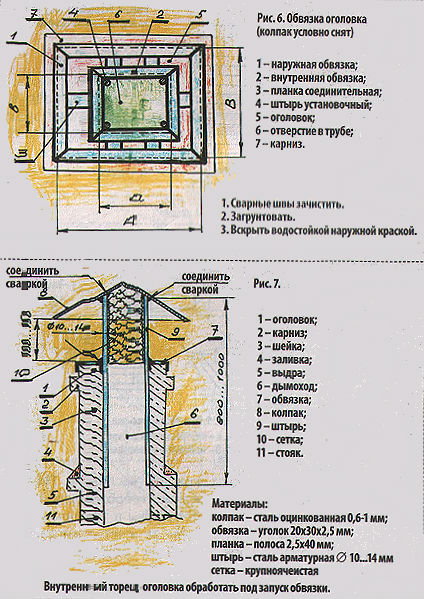

Registration of the withdrawal of the chimney of any heating device outside the roof.

To protect the pipe from destruction under the influence of precipitation, moisture, heating, cooling and other factors, it is necessary to perform the proposed refinement.

This will allow for many years to get rid of its repair.

Pipe outside the roof is shown in Fig. 3.

The location of the transition from the otter to the neck is to bore the cement screed and "challenging" immediately after its execution - to disappoin the cement and moisten from the sprayer (Fig. 4).

Since the sizes of the pipes are different, remove the specified dimensions (Fig. 5).

Make a protective device according to rice. 6.

Bulgarian or gently chisel to ensure a dense girth of the head of the head.

The protective device is covered with paint for outdoor work, pre-applying primer.

To plant a protective device on the leg on the cement solution (Fig. 7).

Remove excess solutions from the outer surface of the pipe.

Bring the pipe into the proper look.

If desired, the pipe can be left without additional processing, whiten, paint.

S. L. Prokhorov, Source Journal "My Lovely Dacha"

Start a discussion ...

Start a discussion ...