The greenhouse today has become an integral element of the country house, a country area. This is a useful construction that contributes to obtaining a stable harvest, regardless of weather conditions, is a magnificent hobby. Grown with their own hands vegetables or fruits are a healthy product, useful for the body.

Profile pipes: species, properties, use

The need for metal profile pipes is relevant for the private sector, as well as for enterprises and organizations of various forms of ownership. For the manufacture of the profile pipe, aluminum and aluminum alloys are used, steel. Technical characteristics - shape, thickness, wall length and diameter of such pipes depends on their purpose and method of manufacture.

Ways to produce pipes

To date, the pipes from the profile are distinguished:

- Cold-rolled electric welded.

- Seamless.

- Cold rolled.

- Electric welded.

- Hot rolled.

Advantages of profile pipes

- Low metal solid design.

- The ability to withstand greater physical and mechanical load.

- Fast unloading / loading, convenient transportation and storage.

- Versatility.

- Ease of structures from the profile.

- Easy in assembling and disassembly.

The practice is proven, the carcass of greenhouses from the profile pipe is a sufficiently strong structure, characterized by a long service life.

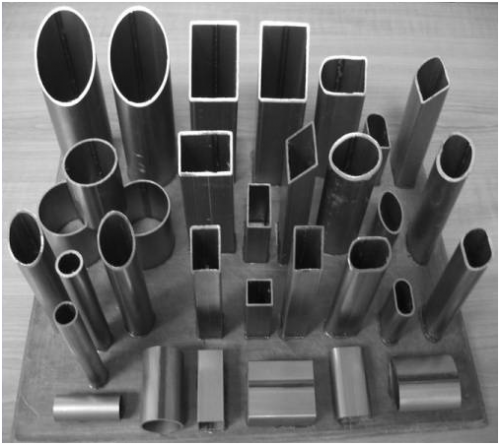

Types of pipes from a metal profile

Aluminum

Due to the high price and for some of its properties, aluminum pipes are not suitable for using them in plumbing and heating systems. These pipes were found in other areas of modern person's activities, they are used as a convenient and lightweight material in facade systems, for the manufacture of railings, window and door structures, advertising, as well as trade and exhibition equipment. Due to the small weight and resistance to corrosion, aluminum profile are needed in the design of interiors of various premises (including residential buildings).

They are needed in the production of sports equipment and equipment, for production. Of these, various economic buildings are erected - greenhouses, greenhouses, summer houses, arbors, verandas, etc. In mechanical engineering, this material is indispensable in the production technology of some structural components. It is suitable for the production of elevator systems.

Steel

Pipes made of steel are produced in several sections, this is a profile pipe:

- Capper.

- Square.

- Oval.

- Rectangular.

- Plane.

- Round.

Due to the high strength of the steel profiles in demand in automotive production and furniture industry, in construction and engineering.

Galvanized

Galvanized iron pipes inside and outside are covered with a thin zinc layer, providing them with the highest rates of corrosion resistance and the maximum long service life. This layer is applied by hot galvanizing. On average, galvanized pipes serve 3-4 times longer than aluminum or steel pipes. The cross section of such a pipe can be rectangular or square.

It is used in the sphere of framework construction of buildings and in the construction and installation sphere, since it is characterized by a high standard of strength. The construction of the greenhouse from the galvanized profile pipe is a guarantee of the quality of the greenhouse design for many years of its operation.

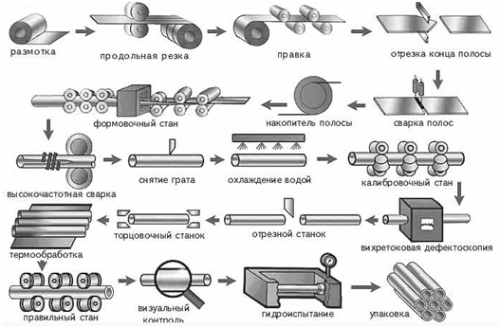

Algorithm produced by profile pipe

Greenhouses: Material, species, features

The greenhouse is a facility of a closed (protected) soil, which includes structures and land plots, allowing various agricultural crops throughout the calendar year. The greenhouses have the ability to regulate the microclimate and the creation of the ideal conditions necessary for high-quality cultivation of a particular plant culture.

Materials for greenhouses

Light greenhouse buildings are popular, since these reliable and useful buildings can be very quick and easy to collect, transfer to another place or disassemble. If we talk about an independent building of small and light greenhouses, then it is enough to purchase the necessary wooden material or a light profile. The construction of industrial greenhouses requires more reliable and durable materials, a professional approach.

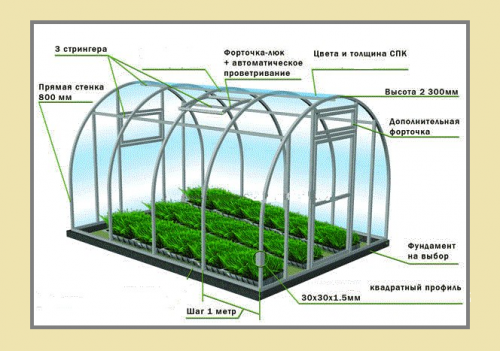

The simplicity in the installation and long service life is distinguished by greenhouses from the profile pipe, the cross section of which is 20x20 or 40x40 mm with a wall thickness in the range of 1.2-2.0 mm values. A profile with a concrete cross section acquire, focusing on the climatic conditions of a specific region, where the greenhouse will be built, as well as on seasonality of its operation, other nuances.

Today, greenhouses from profile pipes are manufactured at enterprises. In order to control the quality and provision of guarantees to the buyer, the manufacturer's specialists carry out a control assembly of the workshop from the professional.

For sale, the design of the greenhouse from the profile pipe enters the dismantled form, it is easily mounted, without additional acquisitions of additional materials and extra effort.

Types of greenhouses

The large range of profile pipes and other building materials on the modern market allows the greenhouse of any configuration and any type. The shape and size of the greenhouse from the profile pipe can be the most different. All greenhouses are classified according to different criteria.

Operating period

- Winter greenhouses (or year-round).

- Spring greenhouses (used in the summer-autumn-winter period).

Ostov

- Frameless.

- Frame.

Frame structures are more reliable and protected from negative weather and climatic conditions.

View of the supporting structure

- Multi-regular.

- Single prupt.

Purpose

- Separate (allows activities on light, air and temperature fluid seedlings).

- Vegetable (growing from seedling).

Coverage material (greenhouse clamping)

- Glazed casing (for coating used glass).

- Plastic casing (for the plating, various material can be used - polymer film, plastic, cellular polycarbonate). Each of them is inherent positive and negative properties.

Output

For the construction of the carcass, the greenhouses are often used PVC (plastic) and metal-plastic, profile pipes. The wood framework is used much less frequently, and for arched greenhouses are not used at all.

For the construction of the heat coating, polycarbonate is most often used, then polymer film. It is quite rarely used expensive glass, the ceiling of which greenhouses is a complex technical process.

Greenhouses: Form and Features

- Arched.

The greenhouse structures of the arched type are convenient when growing low-spirited crops. Note that the arched greenhouses from the profile pipe ensure reliable and long-term operation of such a construction for a long time. The shape of the arched type roof ensures the construction of the ability to self-cleaning from various garbage and snow nans.

- Double.

The greenhouses of this species refer to high designs necessary for growing high and curly plants. They are especially effective when constructing several greenhouses at once close to each other. This is a good solution for the rational use of land.

- Prieucum (or pyramidal).

This design is compact, due to narrow dimensions, it takes the minimum space, which is important in conditions of insufficiency of free land plots. Most often, the pyramid greenhouse is used to grow seeds from seeds.

- Polygonal (or tunnel).

The standard size of the greenhouses of this type is 5 m (height) x 10 m (width). Choose a greenhouse of a tunnel type if you plan to grow plants that need high vertical supports - various curly and tall vegetable cultures. Such greenhouses are very resistant to a strong impetuous wind.

Stages of building greenhouses

As an example, we will look at the construction of arched greenhouses, this is the most economical and simple type of greenhouse type. If you have all the necessary material and a greenhouse diagram from the profile pipe, you can collect such a design in a couple of hours.

Arched greenhouse is distinguished by a number of benefits:

- It is a universal and multifunctional design.

- It is easily mounted, dismantled, it can quickly increase or decrease in size (by adding or deleting new sections) or transfer to another area.

- Due to the arcuate design, not only low-spirited cultures can be cultured, but also plants curly and tall, trees seedlings.

- Such a design can be used as a spring (collapsible) and winter (throughout the year) greenhouses.

- The greenhouse of arched type, like a two-tight greenhouse from the profile pipe, is resistant to supreme gusts of wind, rolling snowfall, rains and plentiful rains.

- The special form of the roof of this structure eliminates the need for its periodic cleaning from the accumulation of various debris, snow or water.

The disadvantages of arched type greenhouses include a problem with providing normal ventilation. There are several options for the device of the ventilation system for arched greenhouses.

- Installation of doors from one end, and from the other - install a window type "Framuga".

- Installation of additional windows of the type "Framuga" from the side and on the roof of the greenhouse.

- The device in the carcass greenhouses of special opening "breathable" sections. This is a rather laborious work, but it fully pays for itself and justifies.

Before proceeding to the construction of the greenhouse, you must choose the right place to do it. It is difficult to do if there is no drawing of the greenhouse from the profile pipe or other material. To accurately determine the "on the eye" the site is impossible even under one such design, if you plan to build several greenhouses, the drawing is extremely necessary.

Search for a sector

The exploitation and efficiency of the greenhouse depends on how much you can choose a place to accommodate this design.

The site selected under the greenhouse must comply with some standards:

- Be well lit. The greenhouse is not placed where tall trees grow. Their big crowns will dim the structure.

- It is characterized by a small bias so that it does not take place around the closed soil.

- From the northern side of the site from the gusty winds and squall precipitation, the greenhouse should be protected by other buildings. In addition, the proximity of the location of residential heated buildings will reduce the heat heating problem in the cold season. It will be enough for only one unit for heating a residential structure and greenhouses. In the case of an excessive increase in air temperature in a closed soil, a good ventilation system should be provided.

- The type of land is light, aligned.

- Provide an unhindered approach, as well as free delivery to the greenhouse of manual type or vehicle transport.

Important!

To achieve the best effect from the greenhouse, it must be properly posted relative to the parties of the world. In order to create the best conditions for the penetration of sun rays throughout the light day, the greenhouse is built so that its longest side is in the north-south direction.

Preparation of the site

If you have already decided on the selection of the site, it is necessary to prepare it, after which you can start at the foundation. The type of foundation depends on the type of greenhouse itself and those materials from which it will be constructed. For example, a simple calculation of the greenhouse from the profile pipe will show that the foundation for a heavy design should be more powerful than for greenhouses from PVC pipes. Foundation works include:

- Aligning the territory of the site, cleaning it from the stumps, roots, bushes, stones and other garbage.

- Organization of taps for rain / melt water.

- Careful preparation of the site as a reliable basis for the frame of the whole structure.

- Foundation building.

For example, for the foundation of the greenhouse from the profile pipe 40x20, it will be necessary to dig a trench with a depth of 45-50 cm, the width is at least 30 cm. To begin with, the boundaries of the future greenhouse are placed on the cleaned and prepared spickers. Then begin to dig a trench under the formwork, which must be set out of the wooden frame around the perimeter of the future greenhouse. The formwork will stand until the cement is completely dry in it. It is unacceptable to build a frame for cheese.

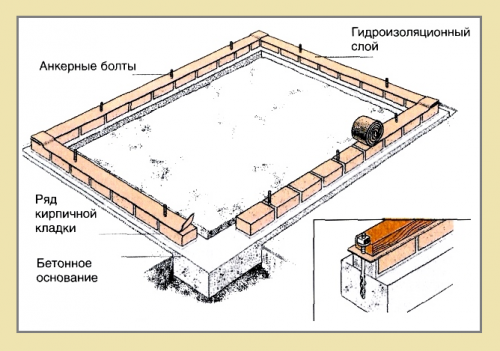

Specialists of the construction sphere are recommended for the foundation to make concrete or stone masonry. The best option for the foundation for a greenhouse made of profile pipes is a reinforced concrete base. It is not difficult to make it, it is necessary to establish the valve, fix it with the wire and pour cement mortar.

The composition of the cement solution:

- Sand (4 parts).

- Gravel (4 parts).

- Cement (1 part).

- Water (0.5 from the share of cement).

Important!

When installing the framework, it is necessary to adhere to the main rule:

Under the light frame, we prepare a light foundation, for a ravory frame - only a heavy and durable foundation.

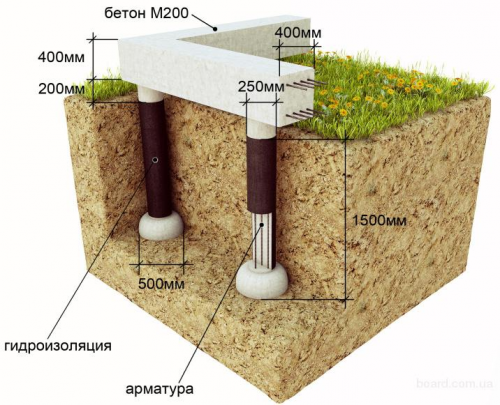

The heavy foundation under the greenhouse can be two types:

- Monolith "tape".

Such a foundation base is able to easily hold the designs and heavier than the frame from profile pipes. Its feature is its structure: for the use of the greenhouse for a whole year, the foundation in width should not be less than 20-25 cm, the depth indicator should be a value equal to the magnitude of the primer of the soil in a particular region.

The "ribbon" itself should be reinforced for the fortress, reinforcing the reinforcement in the corners of the structure with additional elements, for example, metal pins. Together with the reinforcement, they will be reliably fasten with cement mortar into a single base forming a terrestrial base of 30 cm.

- Piles.

As piles, brick (prefabricated), monolithic reinforced concrete or metal elements, placed around the perimeter of the base of the future greenhouse in the following order, can be used.

- In each corner of the perimeter, the base is installed on one pile.

- The remaining piles must be established between them at a distance of 1.5-2 m from each other.

To install heavy piles, it may be necessary to help special equipment. The joints of the piles are carried out using a paintwork, for example, in the form of a shallowly blurred belt basement, or an element such as a metal chaserler. Anchor fasteners are kept docking a metal frame with a concrete basis.

A ribbon foundation from reinforced concrete or bricks must be coated with a layer of waterproofing from the rubberoid or preheated bitumen. Wide square pipes and channels are usually pre-coated with protective anti-corrosion compositions, after which the rubberoid is placed.

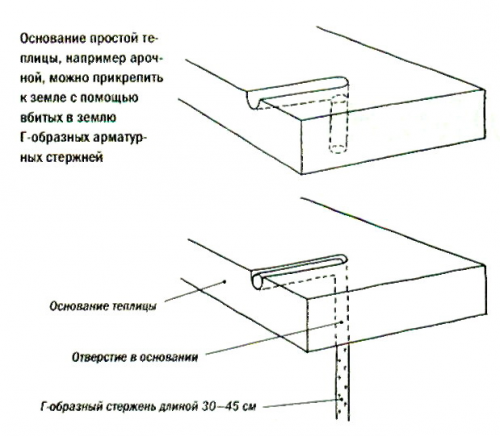

Note that the homemade greenhouse from the profile pipe, like any other design, is going easy enough. The building of the foundation is considered the most difficult or difficult stage in the construction of the greenhouse. The easier the carcass of the greenhouse, the easier it is easier the foundation.

Covering greenhouse

As a sheat for greenhouses use:

- Polyethylene film.

This material is used for small and seasonal greenhouses. The film does not differ in high strength, it does not let a sufficient amount of light and does not correspond to the criteria for a full heat insulating material.

- Glass.

This material is stronger than polyethylene film and misses light, but is distinguished by other shortcomings - low impact strength and high thermal conductivity. Today in the construction market you can find the tempered and reinforced glass, but it is not profitable for buying it to cover the greenhouse. In addition, the glass is too heavy material that requires a reinforced basement and enhance the frame base, since double frames are used to glazing the greenhouses.

- Polymeric material.

It is very easy, durable and economically favorable casing, characterized by good thermal conductivity and transparency indicators that transmits sufficient light. Polycarbonate is an excellent heat insulating material, a little inferior glass in relation to transparency, but significantly wins weight and strength.

The polycarbonate sheet in 4 mm thick provides the level of heat saving, similar to what can be obtained by double glazing. The sheet in 6 mm thick withstands easily massive wind and snow loads, resistant before a hail of 20-mm diameter. The period of operation at polycarbonate is less than that of glass, but this polymer is economically beneficial, it is convenient for work and more reliable.

Example of cross-type greenhouse

The greenhouses of arched type can be seen in the country areas. These are universal multifunctional buildings with many useful features and advantages. They are easily erected, easy to operate, ergonomic and produce, although some disadvantages are inherent in these structures. In this example, we will try together to build a simple arched construction from the profile pipe, considering separately each stage of work.

The size of our greenhouse according to plan is 3 x 5 m, it is the optimal size for the greenhouse, which must be installed on a small summer cottage or garden. In our example, we will adhere to a concrete work plan.

1. Choose a plot, we clean it from garbage, stumps and stones, it should be strictly horizontal.

2. ROOM KOTLAND for the foundation base "Ribbon Monolith". Recall that the width of it cannot be less than 20-25 cm, its depth depends on the level of primerization of the soil in your region. Above, in the section "Preparation of a platform", we have already described the types of foundation and how to build it, you can return to this section in order to study the information set out there.

If you plan to build a concrete foundation, then it is necessary to prepare places for piles, which are installed in the process of filling the RVA concrete along the corners of the perimeter of the site.

3. On the concrete basis, we will lay out the base row of bricks with fixing the anchor bolts. Below is a scheme of a foundation with a protruding concrete base, the basement near the brick and the installed anchor bolts. Also, according to the circuit on the base, one layer of waterproofing from the rubberoid is visible.

4. After drying the foundation, laying the base row, we carry out waterproofing work. The insulating material itself (runner) must be holistic, high-quality, when laying it must be carefully fixed. When filling the foundation with hot bitumen, it is important to make the fill not in one thick layer, but in a slightly thinner layer and sequentially - the new layer falls only after drying the previous one. In our case, waterproofing will be laid on the base brick layer.

On a note:

acquire modern new and expensive waterproofing materials for the greenhouse. Ruberoid and bitumen are the easiest, relatively cheap and reliable insulating material.

We establish arcuate separating frameworks from a galvanized profile pipe with an interval of 1-2 m. This is the optimal distance, if we put them across a larger interval, the design will lose in strength. With a smaller interval, put support does not make sense, as it will only bring additional labor and material.

The rules for fixing the greenhouse carcass to the foundation:

- fastening the carcass of the greenhouse to the monolithic tape or the foundation brick belief is carried out by means of anchor bolts. If the bolt holes are made at the level of the lower docking beams, the studs in the monolithic structure must be installed in the process of filling the foundation;

In the event that Metal Scarlet is used, then the connecting elements (corners, paws and bolts) must be welded.

- the installation of the frame on the wooden beams of the foundation does not require special preparatory work, the fastening of the greenhouse carcass can be carried out by means of self-tapping and special brackets;

- if the beams are supports, then the framework can be fixed on them with "M-shaped" type pins. They are driven into the ground next to a wooden beam or passed through a pre-prepared hole in the beam.

In our example, the greenhouse frame is made of profile galvanized pipes, which give structures special strength and resistance to wind, snow and heavy rain. It is installed on the concrete basis, so such a greenhouse will calmly worry about not one winter.

6. After assembling the frame and fix it on the foundation, it is possible to carry out work on the cutting of the frame by polycarbonate.

The painting of the frame with polycarbonate sheets is carried out quite simply if you purchased a ready-made greenhouse design with a necessary profile, fasteners and fitted polycarbonate sheets for the trim. If at your disposal there are whole sheets of polycarbonate, to begin with, they need to be cut to the necessary elements, and then fix on the frame.

Several tips for working with polycarbonate:

- to properly enjoy a greenhouse with polycarbonate, you need to install all the frame and fix the sheets marked in advance, leaving the loops for the window and doors;

- it is important not to forget that the location of the sheets on the frame should be vertical, and not horizontal, then rainwater and moisture will flush down, and not accumulate in its seams;

- polycarbonate to the frame is mounted in various ways, depending on the type and size of this material itself;

- sheets must be closed with water and frost-resistant sealant;

- to obtain high-quality harvest, experienced gardeners and gardeners are not recommended to install color polycarbonate on greenhouses, since it does not miss a sufficient amount of light than reduces the yield and quality of grown products.

On the Internet, you can find several ways to attach polycarbonate to the metal frame of the greenhouse, everyone has the right to choose the way that it will consider more comfortable and simple. For example, how to do this through thermoshab, can be seen on the following videos:

Important!

In specialized stores today you can purchase automatic systems of watering, heating and ventilation.

The greenhouse on the household site can protect the harvest from bad weather and early frosts, it allows you to grow strong and healthy seedlings to spring. Experienced gardeners will say that for them a greenhouse is a garden and a garden for a whole calendar year. At the same time, that the return to be one hundred percent, the greenhouse should be a reliable, strong and well-equipped ventilation system. In some cases, electric lights are laid and organized heating.

Start a discussion ...

Start a discussion ...