To work on the fill of the bulk gender, it is necessary to approach very responsible. Act clear according to the rules that are set out in this article. And the result of your effort will certainly please you. For the fill, it is first required to perform a tie of concrete or cement and sand. It is allowed, but it is not recommended to pour the floor to the tile or a wooden coating without their pre-editing. To prepare such floors, it is necessary to invest a lot of work and time. After all, the quality of the foundation affects directly on further work on the fill of the bulk. The price of such works depends directly from the type of materials to be used in the work. The cost of filling the bulk can be reduced if the data of work independently. So, about everything more.

A little bit about bulk floors

Advantages:

- The bulk sex will serve you for a very long time.

- Application technology avoids the formation of irregularities and joints.

- These floors are resistant to temperature differences and abrasion.

- Have an attractive look.

Disadvantages:

- The process of applying such floors is quite expensive and time consuming.

Especially relevant to these coatings in the room where there is quite a lot of space without furniture. If earlier they were used only for the design of various public institutions, today they are increasingly used to decorate private apartments.

Instruments

To carry out work on the fill of the bulk gender, it will be necessary:

- Jackhammer.

- Roller for work.

- Wide brush.

- Primer.

- Polyurethane varnish.

- Foamed deformation tape.

- Putty knife.

- Aerial roller.

Special shoes will still need to fill the bulk sex - paint access.

To prepare the solution additionally also need a clean container and drill with a special nozzle.

How to prepare a cement or concrete base for bulk floors

- First, the horizontal surface should be made. If there is a overlap with large drops, then there is no large spending on the casting materials, this coating must first dismantle with the help of a jackhammer.

- It should be traced that the screed is solid enough. Nothing should be flawed and crumble. If there are such sites, they should be dismantled, and after which it is coated with primer and coat with a mixture for a screed. As it, you can use the finished dry mixture, which is usually sold in bags. It dries much faster than a conventional mixture on a cement basis.

- Next, it is necessary to disassemble the crumbling and raging sections of the floor. If this is not done, the foundation cannot be prepared at the level on which it is necessary. Otherwise, undesirable problems may occur when filling the floor (the correct adhesion of the material for the fill with the base is not provided).

- Bulk floors are self-arched fluid. Therefore, before the fill, it is necessary to eliminate the Square, cracks and deepening surfaces. A dry mixture is also useful for this.

- In the process of filling the bulk sex, a temperature and shrinkage should be made, which is a separation between the layer of the blended mixture and the wall. It is he who will protect against the possible deformation of the floor screed when temperatures drops. It should also be immediately before making the fill, over the entire area of \u200b\u200bthe room paste a deformation tape. It also allows you to soften the possible deformation from the supporting structures of the building.

- After drying the bulk gender, the deformation tape is cut. This can be done with a knife. If voids were formed, then they should be filled with sealant so that the necessary flooring is obtained.

Important rules:

- It is very important to observe the temperature regime. The optimal temperature in the room where the fill of the floor will be performed, it is considered 15 degrees and above. In this case, the rate of the solution reaction will also be optimal. If the temperature is lower, the reaction in the stirred mixture will slow down. This, in turn, will lead to the fact that the consumption of the material will increase. In addition, it is possible to change its quality characteristics and colors. At the same time, the room temperature should not be too high. Because in this case the reaction, on the contrary, is accelerated, because of which it will have to speed up the work, which, of course, will negatively affect its result. In addition, the optimal temperature in the room where the work is carried out should not change. It is still required to secure the room from drafts. Therefore, during the work on the fill, open exterior doors and windows.

- It is necessary to follow the humidity in the room. This indicator for cement and concrete base should not exceed 4%. If it is not possible to achieve the necessary level of moisture content, the surface of the floor should be treated with several layers of waterproofing material.

- The base primer is needed to increase the adhesiveness of the mixture with its surface. If not to progress the basis of concrete, then in the future it will lead to a damage of bulk coating. The fact is that when pouring the mixture from the base will be understood to be air. To primed a concrete basis, it is necessary to use a mixture intended for concrete. For the base of cement and sand, you can use conventional primer. All work on primer should be performed using a roller. In places where the roller does not get, you can use a brush. With too dry and porous screed, the coating is faster absorbed the applied primer. Each primer has its time drying, which is usually indicated on the package.

How to prepare a wooden base

- When performing work on the fill of the coating on the wood base, the humidity of the room in which the work is carried out should not exceed the values \u200b\u200bof 10%. It is important to know that the tree immediately reacts to sharp differences of humidity and air temperature. If these indicators are too high, then the moisture is absorbed from the air into a wooden base, and during reduced humidity, wood is narrowed and squeezed.

- On a wooden coating there should be no layer of paint or varnish. If any, they should be removed with a spatula, grinding machines or special washes.

- When the surface layer is removed, it is necessary to poll it with the help of sandpaper. This contributes to the formation of deep furrows, which improve the adhesion of the mixture for fill with wooden floor.

- After grinding, it is necessary to clear the base from the existing garbage and dust. This can be done with a conventional vacuum cleaner.

How to prepare a base with ceramic tiles

- Before filling the floor on the tile, you must first check whether it is firmly glued with the base. If weakly proclinked areas are found, they need to be removed. These places are then embedded with cement mixtures.

- To improve the clutch of the material with a tile, it is necessary to use organic solvents for degreasing the surface. After that, the surface should be primed. Here you will need a primer for smooth surfaces.

Bulk Filling Technology

- Prepare the base under the fill one by one and from the above methods, then wait for about 12 hours if the polyurethane floor is planned and 18 hours, when pouring on epoxy resins.

- Throughout the fill process, it is necessary to ensure that the dry mixture with water is divorced in equal proportions.

Pouring the main layer

- The mixture stepped into the floor.

- Equally distribute the material using a metal strip. For this purpose, you can still use the rocket or truncated rule. In hard-to-reach places it is convenient to use a roller.

- When filling, it is necessary to remove bubbles from the mixture poured. To do this, you can use aeration roller, whose spikes length depends on the thickness of the covered coating.

- For movement over the flooded floor parts, it is necessary to apply special shoes on which we talked above.

- If you need to pour a room with a large floor area, then it is best to make parts in a checker.

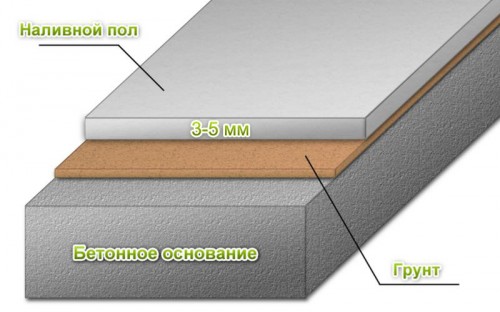

Filling the finish layer

- The thickness of this layer is usually no more than a few millimeters. It is necessary to pour it a few days after the basic fill.

- Filling technology mainly coincides with the fill of the base layer. To preserve the shine and increase the service life of the coating after drying - the entire surface must be coated with a special polyurethane varnish.

Paul decoration

- Today, various multicolored elements are often used in bulk floors, called chips, which are small pieces of acrylic paint. Combining these elements can be assembled very beautiful multicolored decorative images.

- In addition, seashells, beads, pebbles are often added to the solution of liquid sex.

- It is also possible to lay a special film with an image and manufactured 3D-floors under a transparent layer.

Features of laying bulk 3D floors

- The manufacture of such a coating begins directly from the preparation of the base. In order for the floor in the future, it is not deformed and did not spoil the appearance, the reason must be carefully cleansed from dirt and dust.

- The base base should be perfectly even and while rough. For this, primer layers are mixed with small quartz sand.

- The technology of applying 3D floors is almost the same as conventional bulk coatings. Only on a predetermined reason to pre-lay a sheet with the image. In the thickness of the polymer, in addition to the image, you can still place various small decorative items. With good ventilation, such a gender dries about a week.

Bulk Filling: Video

Start a discussion ...

Start a discussion ...