Housing insulation today is one of the most priority tasks for residents living in apartments with offline type heating or private households. Also, this question is relevant for those whose communications are connected to a centralized heating system, but do not receive sufficient heat for comfortable living. In this article, we will consider the most effective method of insulation walls - mineral wool laying technology.

Types of mineral wool for outdoor insulation

High-quality heat insulation helps economically use heating, contributes to the durability of the design, and also provides reliable sound insulation of the room. A certain time for this purpose was used foam. To date, this material is inferior on the operational characteristics of newer types of raw materials and mineral wool acquires popularity.

This term combines a group of materials that have fiber inorganic origin in their composition, as well as modifying compositions. Depending on the material used in the production of materials, cotton wool is divided into the following types:

- Glasswater. This type of material is made on the basis of quartz sand, limestone, glassy and dolomites. Among the advantages of using this raw material, you can note the high porosity, which gives you the opportunity to reduce the size of your volume up to 6 times, as well as the relative cheapness. However, the glass wool in the installation process has one inconvenience - with the laying technology it is necessary to comply with strict security measures and use special equipment. This significantly complicates the process of heat insulation.

- Slagovat has the appearance of loose panels of brown and produced from metallurgical waste. Pretty well protects heat, and also has a low cost.

- Basalt wool is made from rocks containing basalt. It may have both a dense and loose structure. Such material has low thermal conductivity and is not hygroscopic.

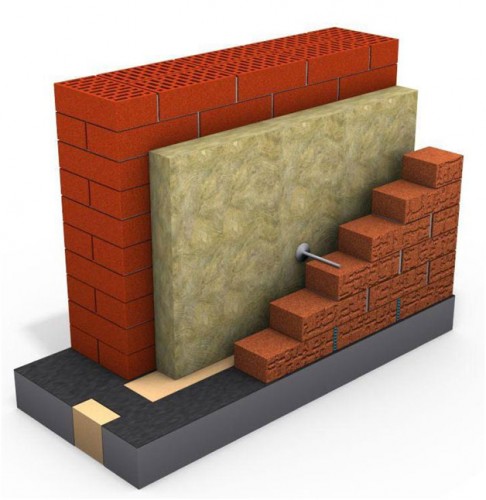

Warming of brick walls outside Minvata Photo:

Wrong plates of Minvati

In the process of insulation of walls outside the Minvata, as a rule, the material is used in the form of flexible plates. But many specialists apply lamella slabs. In these, fiber products are perpendicular to the surface, in contrast to the flexible type slabs, where the location of the fibers has a chaotic character. Due to the smaller size, the laminated plates are more convenient during the installation process, as well as they are quite tightly adjacent to the surface. Another advantage of using this type of minvati is that the products can be fixed with the help of adhesive composition, and not secure self-drawing.

In addition to the construction market, you can find plates of minvati, having two layers.

- the first upper layer has a solid structure, is characterized by good resistance to deformation changes;

- the second layer, the bottom, in its structure soft and well adjacent to the wall, even if there are irregularities on the surface.

Benefits of using mineral wool

Before proceeding with the heat insulation of the dwelling, it is necessary to determine the key parameters that dictate the expediency of using this material. Consider more all the advantages of using mineral wool:

- Good homeproof housing.

- The material has a good resistance to possible deformations.

- Effective energy savings. Vata has low thermal conductivity, as a result of which it allows you to safely save thermal energy.

- Mineral wool has a small weight, which becomes quite a convenient parameter when installing, as you do not need to perform additional strengthening of the supporting structures.

- Easy installation. To insulate the walls of mineral wool do not require special skills and knowledge. With this task, every home owner can cope.

- The material is characterized by good hydrophobicity, so that it does not wash.

- It is resistant to the effects of various chemical compositions.

- Wat is distinguished by durable operational qualities and will not lose its properties for 70 years.

- Also wata fireproof. This important factor allows you to warm this material all the room - walls, floor, attic, roof.

- Another significant advantage of this insulation is its affordable cost. The insulation of walls outside the Minvata is priced depending on the quality indicators and the additional properties of the material. However, this method of isolation remains widely available.

Disadvantages of the use of insulation

The disadvantages include the following:

- The content in its composition is unsafe for the health of substances, in particular formaldehydes. Wool fibers are carcinogenic, so with internal housing insulation, it is advisable to perform a fencing with a special membrane. They will create an obstacle to entering the room of small particles of the material.

- Mineral wool has the ability to absorb moisture well. This will lead to a loss of thermal and noise insulating qualities. In order for such consequences to avoid in the process of insulation, take care of the surface of the surface of the walls with a parobararier.

- In addition, the improper fastening of the insulation in the installation process can cause a shrinkage. Therefore, attention should be paid to high-quality installation.

Features of the insulation of the walls of Minvata

The technology of insulation of walls outside the Minvatu is imposing isolation, both on the outside and internal. With the outer insulation, the wool layer is mounted on the facade of the building. This option has its advantages:

- outdoor housing insulation will not affect the area of \u200b\u200bthe room, which is especially relevant with a small sweatshirt;

- the walls of the building will be protected from the negative impact of atmospheric factors. This in turn will contribute to the extension of the service life of the whole building;

- with the outer insulation in the room, the optimum temperature is preserved. In winter, the insulation will maintain warmly warm, and in the summer, the presence of Minvati will create a comfortable coolness;

- this method will help to avoid formation on the walls of mold and the appearance of unpleasant odor. However, such consequences may entail a violation of technology with internal installation of the insulation;

- also, laying of insulating material outside the building will be positively affected by its appearance.

As a lack of outdoor installation, minvati can be distinguished by seasonality of work.

Experts distinguish two variants of outdoor material installation technology - dry and wet method. Consider the process of performing work in more detail.

Technology dry method

To perform work, you will need to prepare the following materials and tools:

- plates of Minvati;

- primer;

- brushes and spatulas;

- steamproof plaster;

- perforator;

- conventional plaster;

- brackets;

- drill;

- hacksaw;

- tarbed dowels;

- playproof membrane;

- bars for crate.

Step-by-step instruction Performance of work includes the following steps:

- First of all, it is necessary to clean the wall from the old facing material, then cover the surface of the primer.

- If the walls are irregularities, they should be aligned. To do this, we use stucco with a vapor-permeable effect. If there are large irregularities on the surface, they should be knocked down using a perforator or bit. Correcting plaster.

- Next on the wall you need to attach brackets. They will fix the profiles of the crate. To achieve the maximum heat-insulating result between the bracket and the surface of the wall, we place a special gasket. For this purpose you need to apply incompressible material.

- After that, go directly to the installation of the insulation. Using a knife with a long and sharp blade, cut the gap in the plates of Minvati.

- Wear cotton panels on the brackets. At the same time, remember that the minimum gaps should be between them.

- Then you need to drill the hole through the panel for fixing the fastener. We carry out this task using a perforator with a long brown. Fresh slabs in the corners and in their center.

- Next, we insert into the obtained holes of the plate dowels. We perform fastenings so that the tops of the fasteners are well pressed the insulation, but it did not have deformation of the material.

- With nails, we perform fixation.

- To protect the panels from purging, over the insulation, it is necessary to lay a membrane with vapor-permeable properties.

- Then fasten to the brackets metal profiles or bars for the crate.

- Complete panel installation.

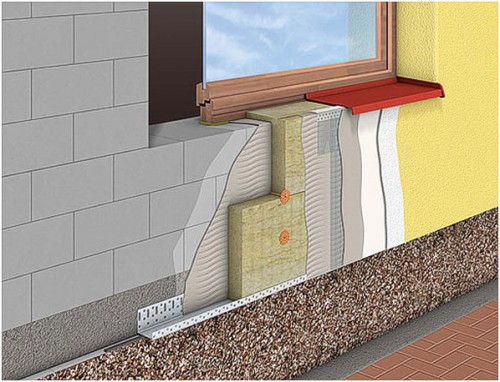

Laying material wet method

To carry out the heat insulation of the home in this way, you must follow the following procedures:

- As in the previous embodiment, we clean the wall from the existing facing.

- Then we processes the surface with a soil mixture and antifungal agent.

- Next, you should define the height of the installation of the first row of insulating plates. At a certain required level, we establish a horizontal metal profile. It will perform a supporting function, and will also become a base for a first row of insulating material.

- Then, on the wall, we perform fixation of the plates of Minvati, applying polymer glue for this. For reliability, each of these plates can be additionally fixed using a dowel.

Important! It should be paid to the fact that the plates fit tightly alone to the other, otherwise the coating can happen over time. - After making the installation, formed due to the use of the dowels of the depressions by eliminating with a putty.

- Aligning the surface accordingly, the polymer soil is applied to the plates. Next to it fix the reinforcing grid.

- At the final stage of work, we make the surface cladding using the plaster.

The insulation of the mineral wool premises does not represent complexity and often does not carry a load on the homeowner budget. However, the presence of such insulation will help create favorable conditions in the room for a comfortable stay and reduce housing heating costs.

Wall insulation outside Minvata Video:

Start a discussion ...

Start a discussion ...