Properly completed finishing of external walls can radically change the style of the building, make it presentable and well-groomed. Today, the construction market offers sufficiently varieties of finishing material, the facade plaster is significant among them. Such decoration of the structure will help not only transform the appearance of the building, but also prevent the appearance of defects on the surface of the walls.

Advantages of plaster

The facade of the plaster has the following advantages during operation:

- this material is universal and is suitable for processing any reasons;

- plaster is characterized by high strength and reliability;

- this material protects the surface of the walls from the negative impact of atmospheric precipitation and temperature differences;

- an important advantage of plastering material is a wide selection of color and texture of the material.

Types of plaster for facades

Acrylic-based plaster, it is also called polymer. This type of plaster has elasticity and resistant to temperature fluctuations. The operational period of this material reaches 25 years. The composition of acrylic plaster includes certain biocidate additives, which protects it from various kinds of microorganisms. Also, this material is sufficiently resistant to the rays of ultraviolet.

As a lack of plastering this type, it is possible to determine its steam-resistant, for this reason it is not recommended to use it with basalt cotton. Also, acrylic plaster has a property rapidly polluted, with the rain it is washed off pretty badly.

Silicate type plaster. The trim of the facade of the house of the plaster of this species allows it to be used in the process of insulation of facades, if the method of insulating bonding is involved. The service life is 25 years. Such plaster, due to the elastic structure, has good resistance to cracks. It is also quite good when dirty, which allows it throughout the service life to have a good appearance. However, this type of material is not recommended to be used with foam flaps, since the foam in this case will not breathe.

Mineral Plaster. Thanks to the cement in its composition, this plaster is the most durable among all types of this material, and its cost is the most acceptable. It has vapor-permeable characteristics, so it can be applied on top of the basalt insulation and foam.

But the mineral type of plaster has its drawbacks. The term of its operation is relatively short-lived - only 10 years. In addition, the material is not resistant to the appearance of cracks and is low-elastic.

Silicone facing composition. Such decorative plaster of the facade of the house for a real day is the most advanced in technological attitude. Stuccoing of silicone type elastic, vapor permeable, has a sufficient stretching rate. It is not difficult to wash off the pollution from it, due to which it can be used to finish the facades of buildings that are located near the road. But the cost of such a material is quite high.

Decorative plaster. Her task is mainly in the embodiment of various design ideas. With its help, you can achieve the embossed and smooth surfaces of a wide variety of shades. In addition, with the help of decorative plaster, you can create imitation of more expensive types of finishes.

Decorative plaster facade photo:

Recommendations for finishing

In order to properly apply a layer of plaster cladding, it is necessary to consider a number of key characteristics of the process:

- Plastering layers should be applied to the working surface with layers of the same thickness. Otherwise, the surface will dry unevenly, and the thin layer will not be able to hide the irregularities of the wall.

- In obligatory before the start of work, it is necessary to prepare the surface of the wall and clean it from pollution. When you ignore this condition, the adhesion of plaster and base will occur badly, and the layer applied is uneven.

- Do not stucked the walls that are freezed. In this case, ice is based on, which will prevent the fastening of the composition, and during its melting there will be a lagging material.

- Hot weather is also a forbidden condition for work. The plaster at high temperature will quickly dry, and unwanted cracks can be formed in it.

- It is not recommended to take breaks during the work. This can lead to the formation of spots on the walls. When finishing with colored plaster, you need to immediately prepare the necessary material for the entire surface being processed.

- In order to understand how much material it is necessary, you should proceed from the processed area and the average consumption, which is declared on the packaging by the manufacturer. An additional 10% of the material for possible losses in the process should also be added.

- The consumption of plastering is determined by the size of the grain. You will need a larger amount of fine-grained material, but the composition used is enough for the processing of the larger area of \u200b\u200bthe wall.

Preparatory work

Before performing the process of plastering the facade with your own hands, it is necessary to produce certain preparatory actions. Consider them in more detail:

- From the walls you need to remove all existing pollution, otherwise the adhesion of plaster composition with the base may be insufficient.

- Clean the walls should be manually using spatulas or brushes from steel material. If necessary, if pollution is significant, it is necessary to use sand - and water jets.

- Specially designed solvents should be used to remove bold spots. After that, the surface is cleared of dust by means of compressed air. Then we remove the surroundings of the solution using a double-pointed hammer for this purpose.

- It is necessary to perform external waterproofing of the walls, to complete the process of roofing, also equip the floors and fencing of balconies.

- The window and door screens of protective destinations should be installed, as well as devices for fastening drain pipes. And only after that proceed to apply plaster composition.

Technological process finish

When finishing the walls of the facade, it is very important to pay attention to the temperature of the working surface, which should be from 5 ° C to 30 ° C. Also on air humidity - this indicator should not exceed 70%. Remember that it is not necessary to finish immediately after atmospheric precipitation, especially in time. Also, work should not be performed in the case of a wall of direct sunlight on the surface. The rest should be followed by such a sequence of actions:

- You can apply the plaster in two ways: manually, with the use of tools specially designed for this purpose, or by applying staining stations.

- To fulfill the finish, you need to install the necessary layouts in advance, as well as forests and hanging cradles. Immediately prepare the necessary tools and solutions.

- Starting the decoration should be applied with aligning plaster.

- After that, it is necessary to wait until the material is completely frozen.

- If you wish, you can achieve polished effect. To do this, on an even reason we put a putty and wait until it reaches. Then we seel the wall to the shine.

- In the next, the surface of the wall must be covered with primer. This will make it possible to reduce the amount of finishing composition. Also, the use of primer will ensure good adhesion of the plaster mortar, they will be fixed and polymerized, they will make it homogeneous.

- After drying the primer, the surface is coated with the composition of decorative plaster, and on top of it, if necessary, we apply to the paint.

Plastering the surface of foam concrete walls

If you need to apply plaster cladding on a foam concrete surface, you need to consider a number of such features:

- When finishing the facade walls, the type of plaster, which will limit moisture access, will create a stable barrier to the appearance of cracks and provide vapor permeability. This will contribute to the best thermal conductivity and frost-resistant material.

- When finishing walls from foam concrete, the thickness of the plaster layer should be 5-10 mm.

- Good thermal conductivity of plaster will provide moisture output. This will allow moisture not to linger under the outer layer of plaster, which will prevent the premature destruction of the walls.

- For foam concrete surface, the plaster with a high adhesion ability should be used, since due to the foaming component, the adhesion of plaster with the surface of such walls is problematic.

Coating plaster concrete walls

If the surface for the cladding consists of their concrete slabs, it is necessary to take into account the following features of the plastering process:

- On the walls of concrete material during the installation period, defective changes in various character - cracks, chips, depressions and influx may be formed. It can prevent good fastening of plaster to the base. To correct the situation, defects should be eliminated by spatlery.

- Before finishing the concrete surface by means of plaster, to strengthen the base should be treated with a solution of primer or a certain firming composition.

- Application can be mechanically using the paintopult, as well as manually using a roller or brush.

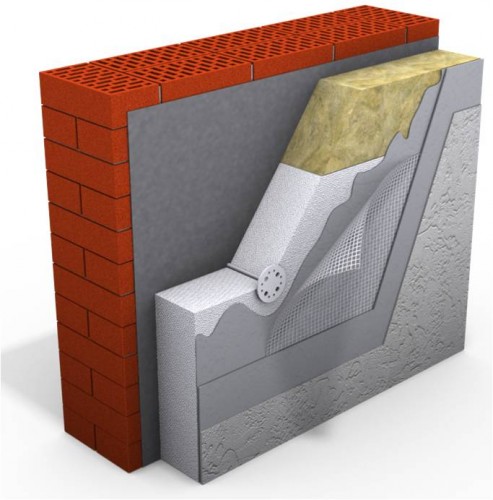

- Since concrete is a material that does not absorb moisture, the plaster should be applied in three layers - spray, primer and covers.

- The first layer, spray, should be liquid consistency and have a thickness of 3-5 mm. The second layer, the soil must be more dense and its thickness should be 7-10 mm. The coverage should also be thick consistency and applied with a thickness of 4-7 mm.

Plaster brick walls

In order for a solution of plaster is better attached to a brick surface, such features of the cladding process should be taken into account:

- Initially, you need to make a notch on the brick. You can also put a fine mesh from a metal material under the stucco.

- Next, we make splashes, cover the surface of the primer and perform the crossbar using a solution of similar consistency.

- It is also necessary to pay attention to the fact that the seams between bricks are separated to the necessary depth. Otherwise, the plaster layer will swear and eventually fall off.

How to execute the facade plaster on video is presented below:

Start a discussion ...

Start a discussion ...