The foundation of your home is its basis. And at the beginning of construction, it is necessary to think about how it will be and how to make it reliable and strong. The best solution is a slab foundation. About why it is so, and how to make it with your own hands, you will learn now.

Features and advantages

The slab foundation for the house is the optimal option for building in conditions of weak and loose soil. It will create a reliable layer for finishing floors, save your money and time. Thanks to him in the future erection of the house, you can set the inner walls in the room where you consider it necessary, without being based on the mandatory requirements of the same pile foundation. If you do all the work on our instructions, the walls and foundation will become a single design that can withstand heavy loads and for many years not to give cracks and not deform even on the most unstable soil.

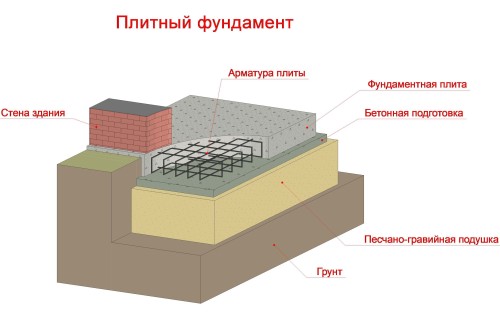

Device of slab foundation

The base of the slab foundation is quite simple - a cushion from rubble and sand, a solid stove and reinforcement. A layer of tightly rammed sand and rubble serves as a reliable and quite simple foundation, which costs pretty cheap. The armature that you will use should have a thickness of at least 1.2 cm. It will be installed in two rows. The edge of one cell at the same time in most cases should be up to 30 cm long.

It is very important that concrete will be covered in one right. It will be the key to the monolithic of the entire plate, which means its reliability and strength. Therefore, it has a list of the following requirements:

- it must be high-strength material. Concretes are widespread B22.5 or even more durable;

- waterproof. Its coefficient must be at least W. The higher the better. Especially in those places where the groundwater is close to the surface;

- resistance to low temperatures. Level no less than F200;

- mobility indicator - P-3.

The price of the slab foundation is mostly different depending on the quality of the materials you choose. But if you make the main work with your own hands, you may not save on materials and tools, because it does not have to spend money on builders services. It is possible that you decide to make the foundation of the house from ready-made reinforced concrete plates. Often they are used during panel construction. Such plates are distinguished by a consistently high quality, but for their use you will need a crane and bulky equipment. Especially since the superficial screed still have to do. Therefore, we would not recommend them to you in most cases. Their cost in most cases is sufficiently high, although the strength can significantly give up a monolithic plate that you can do yourself.

Start with the calculations of the foundation

When you finally decided to make a slab foundation with your own hands, the first thing you have to do is to produce accurate calculations. The thickness of the slab foundation may vary in the range of 15-40 cm. However, there are cases when the foundation is needed threatening and even stronger.

When you think about which thickness should your slab foundation, pay attention to the following items:

- the characteristic of the soil on which a new home will be erected;

- the total weight of the building. Take into account not only the "box" itself with the roof, but also the weight of furniture, tenants, equipment, equipment and even snow cover on the roof in winter.

Also, take into account that the foundation of the walls, columns, soil, which will necessarily be at minus temperatures, soil repays and so on. If the building is more, and the walls are thin and in general a little bit, then the pressure turns out to be local. The same applies to the soil. It may have different moisture in certain areas, which also has a localized action on the foundation. All this he must withstand, do not succumb to strain and not crack.

The simplest and affordable calculation scheme does not require special efforts, but in practice it turns out to be effective. The foundation for light-storey structures should have a thickness of at least 15 centimeters, for brick houses - from 20 centimeters, for large buildings in several floors - about 40 centimeters. It is unlikely that you will independently build a multi-storey house with a large area, so the top plank at 40 cm for you is likely to be final.

If you repeat about local loads, you can find the foundation of rigidity ribs. If you yourself do not risk to make miscalculations, you can order a specialist about a specialist, and already based on it, start working.

Getting to construction

The construction of a slab foundation should occur in stages and in strict accordance with all technological rules. The most common thickness of the slab foundation is 25-30 cm, so we will proceed from these values.

- If in a place where the house, clay soil will be erected, it is necessary to replace it with gravel or sand. To carry out this, you need to initially make markup. Select where the corners of your home will be located, make an indent 1 meter towards expansion and drive the peg. Between them stretch the rope. Through it, cut the depth of one and a half meters, remove the clay, pour sand and gravel. It is very important that the surface at the same time is smooth. From time to time you need to check with the construction level. Even a slide on one centimeter with a total area of \u200b\u200b100 square meters becomes the cause of recalculation to one cubometer of concrete.

- We proceed to the exact markup. We indicate where we will have the walls. The most important thing is to preserve perpendicularity. It all is done with the help of pegs and threads.

- Now you need to erect the formwork. The design is quite simple, but the wrong installation may cause concrete leakage and design deformation during operation. For formwork, you can use almost any materials, but do not forget to put the backups that will hold them. The design must be as tough as possible. To check it, you can just kick the formwork. If it is withstanding, it means everything is done correctly. Do not be afraid to break it. It is better to be restrained than getting a broken formwork already in the process of concreting.

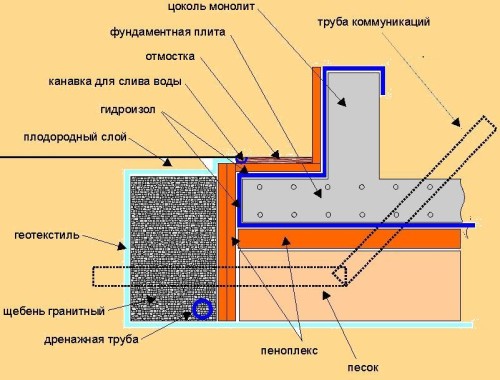

- Put a layer of waterproofing. Please note that it must be put on a dense surface. Sand, even tightly rammed, does not fit for this. To prepare the surface, you need to sprinkle with the sand cement. Consumption must be approximately 1 bag per area of \u200b\u200b9-10 kV. m. Put the cement evenly and jump up with rake with a small step of teeth. In this case, sand and cement on the upper layer must be mixed. They should shuffle to a depth of 5 cm. When finished, paint the whole area with water and let me dry and grab. This layer will become not only reliable soil for waterproofing, but also to prevent the access of rodents and other pests to the waterproofing layer in the future.

- The technology of slab foundation does not provide for large expenses. Therefore, as waterproofing, you can use a simple polyethylene film. Its thickness should be at least 400 MK. Polyethylene himself perfectly restrains moisture and has excellent stretch properties. As is well known, with time, polyethylene is not amenable to rotting and other destruction. Thanks to this, he will perfectly protect the foundation from moisture for many decades.

- When you start reinforcement, it is best to take fittings with a diameter of 1.4 cm. It is relatively light, but strong enough. The length of one reinforcement should be less than the place where it will be installed for ten centimeters. It is necessary so that the metal does not in contact with the soil and did not rust. Better let the reinforcement be shorter than the longer the necessary. The reinforcement needs to be folded the grid so that the cell is about 20 cm. Between itself, the valve is fastened with steel wire. Do not use aluminum or copper. They will give a chemical reaction, which over time will lead to the destruction of the frame. As an option, you can use kapron ties, but the cost of them is higher, and they do not significantly simplify the whole process.

You need two such arrays. The distance between them should be 20 cm. Take care so that the bottom grill on the bottom of your pit. Raise it and secure at an altitude of 5 cm in any way available to you. The upper lattice should eventually be relended into a concrete by 5 cm. Thus, in the amount, your slab will have an altitude of exactly 30 centimes.

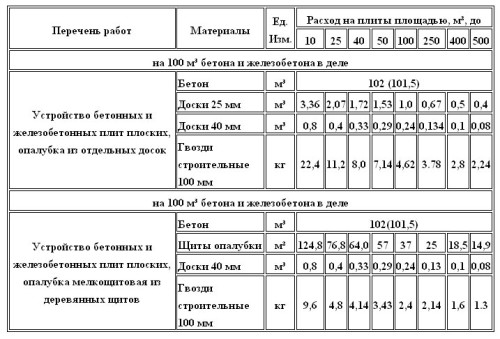

- Now you need to calculate how much concrete is needed for the entire stove. If your plate thickness is 30 cm, and the width and length - 10 m, you will need 30 cubic meters of concrete. Reliable to order it at the factory directly from the manufacturer. Today there are many poor-quality products that are strictly not recommended to be used to fill the foundation. When buy enough concrete, make a solution in the concrete mixer and pour into the pit. It is better to start early in the morning to have time to completely fill the entire area before drying.

Important! You can start only when all the preparatory work is made and rechecked, and you have enough of the material. The account can go for hours and minutes. If the formwork collapses during the fill, this can be a serious problem, because concrete quickly solidifies and fix the situation will be very difficult.

- When concrete is completely flooded, it is necessary to put it, and the air that is formed in it is to squeeze the vibrator. Buy it optional. You can rent in a construction store. Full binding of such a foundation takes about five days. Up to this point, go on it or subject to any loads is not recommended.

Now you know how to make a slab foundation with your own hands and without attracting specialists. However, remember that at some stages you will still need help. For example, at the pouring stage of concrete or digging the pit. Successful construction!

Start a discussion ...

Start a discussion ...