Since ancient times, the bath was part of the Russian culture of the organism. And several dozen years ago, physician scientists conducted clinical studies and confirmed that a slight overheating of the body in the room contributes to a positive effect on the body.

So a bath for a person:

- helps the body to destroy cells whose DNA is developing along the way of rebirth into cancer;

- helps to remove slags;

- cleans the pores of the skin and normalizes thermal exchange in the body;

- positively affects immunity;

- inhibits the aging gene.

Modern connoisseurs of light pairs seek to equip a bath on their homestead. At the same time, many prefer to build a bath, and especially the oven for her, with their own hands. Of course, you can buy a factory oven, but such products are very expensive and can not always meet all customer conditions.

Content

- Bath furnace and sauna: differences

- Square Bath and its device

- Determine the required power of the furnace

- Arrangement of Kamenka

- What is made of a bass oven

- What you need to take into account before the construction of a stove for a bath

- Metal welded stoves for baths do it yourself

- Construction of a brick furnace for a bath

- Construction of a brick furnace for a bath: video

Bath furnace and sauna: differences

Temperature and relative air humidity. In the Russian bath, the temperature ranges from 50 to 70 degrees with high humidity (50-75%) - as a result, soft pairs are formed. In the sauna, the pairs are dry: only 15% air humidity at a temperature of 90 degrees (in some cases it can reach 130 degrees).

Microclimate and its impact on man. Both in the bath and in the sauna there is a heating of the body and the active excretion of slags from it through the pores of the skin. The principal difference is that the wet air of the Russian bath has greater heat-conductivity, so in order to break the body well, at temperatures above 70 degrees, there is simply no need. Moreover, since the humidity of the air in the bath (up to 75%) is slightly higher than the humidity of the habitual air on the street on the street (60%), then the person does not have such a strong stress from overheating, as it happens in the sauna. That is why the bath is less likely to occur spasm vessels, rapid heartbeat, sharp jump blood pressure.

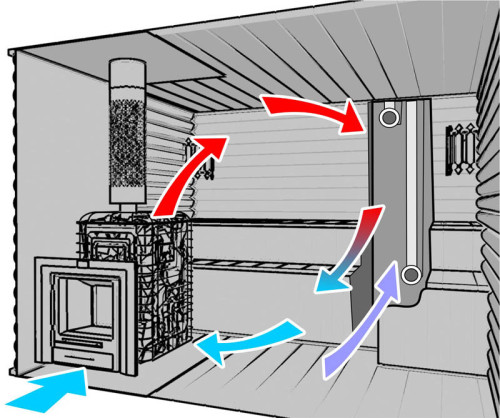

In the circulation of air in the steam room lies another fundamental difference between the Russian bath from the sauna. In the sauna, the air circulates constantly and quickly through the cavities in the furnace - that is why steam in the sauna is dry, and the temperature difference below and at the top of the room is minimal. In the steaming Russian bath, the air practically does not circulate, and gradually rises from the bottom up, thus preserving its humidity.

Device furnace. The heat transfer of the walls of the furnace in the Russian bath should be minimal - that is, the oven heats only the stones, and not the air in the steam room (this is one of the main differences in the Bath furnace). Experts believe that if the furnace warms the room to a temperature above 40 degrees before placing water - then the furnace of poor quality. The furnace is most often from the pre-banner, and in the pair itself only placed the door to throw water. In the sauna, everything is arranged differently: the stones lie openly, the air is heated to very high temperatures. Therefore, steaming in the sauna relies, alternating the effects of hot air and cold water of the pool.

Couple quality. In the Russian bath, steam is light, it is he who is an indicator of the quality of the Russian bath. Course is formed when they throw water on the hot stones of the furnace: the higher the temperature of the stones, the smaller it turns out steam. The air becomes hot, but does not burn the respiratory tract.

- stones are heated in a closed furnace;

- when there is a need to pose a couple, the doors of the furnace open and throw water;

- the rest of the time the furnace is closed.

The broom is a constant attribute of the Russian bath, without which it is simply impossible to do. With it, massage is made, the leaves also distinguish with the useful substances in the microclimate of the steam room. In the sauna brooms are used much less frequently:

- due to the high temperature, the brooms dry and shuffled;

- there is no need for additional stimulation of sweating at a high temperature.

Square Bath and its device

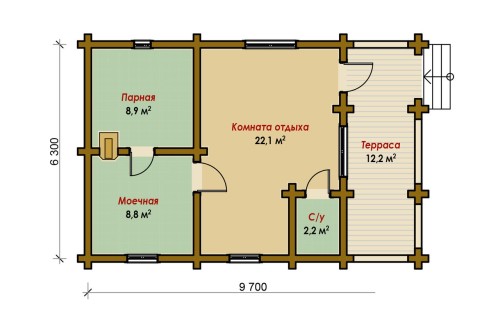

Baths can be different in the area. What will you build are the question of individual opportunities. But regardless of the bathhouse, there are several zones in the room: several zones are distinguished:

- Pregnant. It is intended for undressing before the procedure, as well as (if the pregnant is warm) can serve as a place for gatherings. Modern prebates are equipped with various necessary equipment (for example, a TV and a refrigerator), a sofa, chairs and a large table.

- Washed. The name speaks by itself: wooden shops, as well as basin, barrels and cans for washing are placed in the traditional type. You will need towels and hooks that can be broadcast. Soap and other bath accessories at the request of the owner. If you prefer modern methods of washing, you can equip the watched shower. In any case, when building it is important to provide a good draining system.

- Pair. The size of the steam room can be any, but the optimal is considered to be 5 m 3 - In the premises of such a volume, all the necessary processes are better flowing. The room is equipped with benches and shelves for seating or lying, which are fixed at different levels. If the walls of the steam room are not built out of linden or birch, they are refined: other types of wood can highlight resins that cause skin burns. All necessary inventory in the steam room should also be from a tree.

The kind of furnace is also directly dependent on the size of the steam room:

- for medium-sized wage (30-40 m 3) the cast iron casting oven is suitable;

- for a small - welded from a steel sheet, made by hand;

- for big - brick oven.

Determine the required power of the furnace

The traditional Russian bath is a log house from logs and Bruusyev. Mild is called a bath arranged from linden or birch (suitable for the improvement of the whole family, including children), and a heavy-oak bath (wood highlights heavy tannile substances: such a bath for strong health men).

It is not desirable from the nut, maple, ash and coniferous rocks of the trees in the bathhouse: after a few years of permanent operation, such bars will begin to allocate volatile substances that can harm human health. For the sauna, the wood breed is not as principal - you can build even from aged pine.

From what kind of wood tree you choose to build a bath, the necessary thermal power of the furnace depends:

- for a light bath from the linden, it is 0.5 kW / 1 m 3;

- birch - 0.7 kW / 1 m 3;

- for oak - 1,2 kW / 1 m 3.

Such calculations will be correct for the room, the height of which does not exceed 2.5 meters. Actually, it is usually not built above.

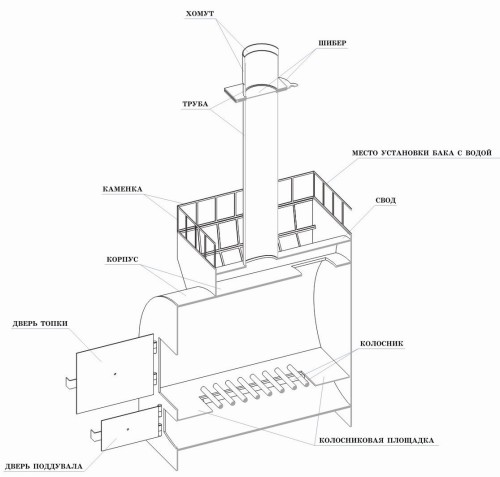

Arrangement of Kamenka

The oven in the bath is always a stove-heater. It has a constant container for heating stones, which serve as a kind of thermal battery: accumulate heat during the protest of the furnace, then emit it. This radiation warms the walls, gender and air in the bath. There are two types of heater:

- Deaf. Kamenka and furnace in the furnace are divided by a partition. As a result, the stones always remain clean: they do not need to wash them. Stones are laid in a special order: the smallest (sizes 4-5 cm) lay down to ensure a large area of \u200b\u200bthermal contact, and large - up. However, the deaf stone heats slowly due to the small area of \u200b\u200bcontact with stones and fireboxes. This disadvantage is noticeable if the oven is more minimal. For this reason, it is satisfied with a deaf heater only in the furnaces with a capacity of not more than 25 kW: the furnace with a deaf stone can provide a light steam bath with a volume of 30-40 m 3. It is also important to know that if the ceiling height in the bath is more than 2.2 m, then the construction of a deaf stone can lead to the formation of a heavy steam.

- Flowing. With such a device, the Kamenka furnace is located directly above the furnace on a special lattice. The entire area of \u200b\u200bstones warms up quickly and evenly. In the process of hardware equipment, large stones are laying down, and small - upstairs. Therefore, the flow chamber can be done in the furnace of any size.

- construction of a flowing stove is much more complicated: you will need to equip a hermetic purifying hatch;

- sticking the furnace is allowed only to firewood that do not give in Nagara;

- stones should be regularly removed from the furnace and clean.

For arranging the furnace, stones are selected with heat-conductivity higher than that of the material from which the furnace (brick or metal) is made.

- basalt;

- gabbro;

- talco chlorite;

- diabase.

Such stones are dark, heavy, very smooth and have a rounded form. The shape of the stones is of great importance: if the stone is round or oval, then the ratio of its surface to the volume is the smallest - this ensures the optimal heat transfer mode.

Completely unsuitable for the marble, dolomite and limestone. First, they do not comply with the requirements of accumulation / heat transfer, and secondly, with regular heating, organic evaporation harmful to humans is beginning to be allocated.

What is made of a bass oven

Bath furnaces can be several species. To stop your choice on one of them, first decide on the size of the bath and material for its construction.

Welded sheet metal furnace is suitable for a country bathhouse with a size of no more than 25 m 3 (one or two compartments). Such a furnace heats up very quickly (after an hour and a half after the extracts it will be possible to steam) and quickly cools. In order for the pair to visit a family of 4-5 people, the furnace will have to be periodically pouring. If errors were not allowed during construction, then the pair will always be easy. In addition, with time, the metal is not cracking and does not need a regular protop.

Brick oven. Correctly erected brick oven will give light steam in the bath of any volume. It is very important to choose the building materials of the highest quality and explore the basics of the work of the liver. Brick furnaces are built in large on the grounds of the baths (3-4 compartments).

- build a brick oven only with flowing heater;

- the required number of stones for the heater - 120-150 kg;

- to cook the bath, you will need to make it 3-4 hours;

- if the oven did not function more than 5 days, it must be dried and to be sucked to avoid the appearance of microcracks in the masonry;

- the consequence of the appearance of microcracks may be a refinement in the bath.

Cast iron cast oven. This is the best option if you build a multi-sized multi-sized bath in its own area. Attending it will be able to members of your family and friends.

- cast iron has a high heat capacity;

- the cast iron boiler is convenient to use;

- its cost is not high compared to the construction of a brick furnace;

- all furnaces for industrial production bath - cast-iron;

- there are many models on sale, including equipped with a water circuit.

What you need to take into account before the construction of a stove for a bath

What type of furnace you will not choose, you must take into account several of the most important items so that the structure is not only functional, but also safe.

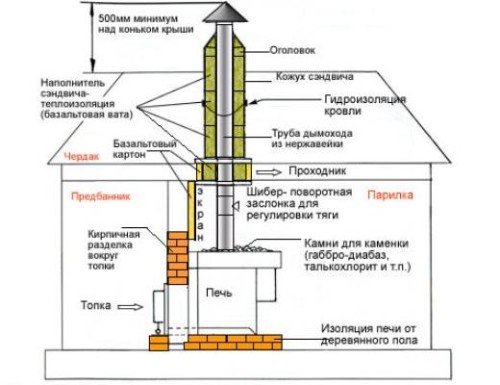

- Foundation. The surface for installing the furnace should be perfectly smooth: from concrete or brick. From above, the foundation is placed with alabaster cardboard (12 mm), and then a metal sheet (up to 5 mm). This will provide a proper level of fire safety. The protective layer should be more furnace area, and in front of the door play 50 cm minimum.

- Chimney. The wall, through which the chimney comes out, should be built of refractory bricks. Part of the chimney, which goes outside, is equipped with thermal insulation protection - it is necessary to avoid condensate formation. The most secure and reliable experts consider chimneys from ceramics and stainless steel.

- Provide fire extinguishing products. Whatever reliable in your opinion the design of the furnace, do not joke with your security.

- Protection of walls and ceiling. Walls made of wood near the oven necessarily protect the brick masonry or metal sheets. About the protection of the ceiling is often forgotten when building a bath. It is very important over the furnace to fix the basalt cardboard layer or a metal sheet whose area would exceed the furnace area.

- Fuel for a furnace in the bath. Only firewood can be fuel for a bath furnace. It is in the process of combustion of the tree that can ensure the correct heating of the steam - from the walls to the center. Replace firewood if there is no possibility to buy them, you can cheaper fuel pellets (made from sawdust or straw). When furnaces, the volatile components will quickly burn out the carbon, then carbon is tweaked for a long time. Therefore, if you drown a carbon with coal - steam will be heavy.

Metal welded stoves for baths do it yourself

Burning bake for a bath

Metal bubburshka oven - one of the most common types of welded stoves for a small bath (up to 20 m 3) In the country area.

- it is quickly heated;

- it is easy to make and install without the help of specialists;

- takes up little space;

- installed without foundation - just to basalt cardboard;

- reduces the risk of poisoning by ugar (does not crack as a brick furnace of poor-quality styling).

However, the disadvantages of the design also have, among them:

- fast cooling;

- the surface of the furnace is strongly split - you need to be very careful not to get a burn;

- walls, gender and ceiling around the furnace require special protection in order to prevent fire.

To make the most simple burzhuyku for the bath you will need:

- steel sheet (sheet thickness from 8 mm);

- pipe with a diameter of 50 cm;

- pipe for chimney;

- metal rod (diameter 10 mm);

- colonsets.

How to make:

- Rush into a small tube (20x5 cm) a hole for pondered.

- Welcome fastening for grateheads above the confusion.

- Install the door for the furnace (20x25cm).

- Brew rods to create a heater.

- Make a hole to throw water.

- Prepare the lid from the metal sheet: we ride the chimney hole in it.

- We weld the lid to the heater.

- The height of the chimney must be at least 4 m.

Installation of burzhuyki in the bath:

- Mount the furnace so that the distance to the wall is more than 1 cm.

- Protect the walls with a bath with foil or brick masonry. This will help prevent wood overheating or its fire.

- After installation, make a chimney insulation.

- The burzhuyk can be chosen by bricks to give her a more attractive view, as well as protect against possible burns when contact with a hot metal.

Metal Pipe Bath

This is perhaps the easiest way to make a stove for a bath with your own hands. You will need trim pipes 150 cm long and a diameter of 50 cm. The thickness of the metal must be no more than 1 cm, otherwise the furnace will warm up too long.

- Prepare the foundation from concrete 25-35 cm high.

- When the foundation is freezing, put the platform from a red refractory brick in two rows to which the furnace will be installed. Size 70x70 cm.

- Remember that in the construction of the furnace only the clay solution is used.

- Wooden walls in the installation site of the furnace protect the brick screen with a height of at least 1.2 m.

- Install the furnace at a distance of 20 cm from the wall.

- Divide the pipe-blank to 2 parts:

- 60 cm long (will be used as a water heating tank);

- 90 cm long (firebox equipment and heater equipment).

- At the bottom of the pipes, ride a hole for pondered (20x6 cm).

- In the confusion, place the grate. To do this, weld to the pipe 4 ears for which install the grate.

- Rent a niche for the furnace in the tube and equip it with the door (25x30 cm).

- Welcome a metal rod for the fire fencing and put stones.

- We weld to the top of the oven oven from the steel tire.

- To the end of the water tank for water breed a metal circle (8 mm thick), rush in it a hole and breed chimney.

Construction of a brick furnace for a bath

Necessary materials:

- Bath furnace should be built from chamotte brick.

- Finish is allowed to finish with conventional brick parts of the furnace, which are not in contact with the flame and smoke.

- Suts between bricks and between brick and metal parts should be 6-10 mm.

- All metal parts should be made of cast iron.

- For the construction of a lattice Kamenka will need chawliers.

- The medium fatty solution consisting of clay and sand in the proportion of 1: 1. The fatty solution when kneading is determined as follows:

- smooth wooden stick Lower into the solution;

- the solution of suitable quality will remain on the surface of the wood, forming a layer with a thickness of 2 mm.

- Sand will choose the calcined and washed. River sand is not suitable for the construction of a stove for a bath - it can cause the appearance of microcracks.

- Facing the furnace is performed by smooth bricks with rounded corners (the form is important to enhance the heat transfer of the surface).

Bricklaying:

- The construction of the furnace should be started in the warm season.

- For the construction of the Bath furnace use the Dutch principle of masonry.

- A metal sheet is put on the prepared foundation.

- The first row of bricks are laid without a metal solution.

- Seams between bricks should be 3 mm.

- After all rows are laid, the furnace should dry about two weeks.

- Only after drying lay the heater.

- Overclocking furnaces are made 4-5 times with a break at 12 o'clock.

- For the first furnaces will need the firewood of the highest quality.

![size_m3 [1]](http://dachnaya-zhizn.ru/images/dacha/size_m31-500x362.jpg)

Start a discussion ...

Start a discussion ...