Wooden windows can be done with their own hands. The main thing is, to observe the tightness and geometry of the design. It is believed to achieve the same quality as the windows made on the machines are impossible, but it is not.

Preparatory stage

If you make windows with your own hands, it will cost much cheaper than ordering the finished glassy. It is especially true that when you need to replace the old window, which has become unusable in the country. Soundproofing and heat-saving properties in wooden windows are lower than that of plastic, but they are environmentally friendly. You can perform the window frame in two versions:

- A classic swing window, whose sash is revealed and can be cleaned.

- Sealed glass, which does not need internal cleaning.

Before making a wooden window, you need to choose the material. This stage in the manufacture of windows is focused on, because the quality of the product depends on it. Expensive windows from oak, but they are considered the most durable. Oak is quite difficult to process, but it is beautiful in the finished product. In addition to oak for the manufacture of windows, also uses:

- ash;

- beech;

- pine;

- birch;

- larch.

Separately, you can select windows from larch, they look beautiful and serve for a long time. Using this breed, you can be sure that the windows will have:

- high density and hardness;

- resistance to fires;

- long service life;

- resistance to rotting.

The larch identifies special substances - phytoncins that kill pathogenic microbes. It also contains antiseptic substances that are struggling with the advent of fungus. Larch is the best option for windows in rooms with high humidity.

You can use non-solid boards, but, for example, glued bar. This material is practically not subject to shrinkage. And this means that after mounting the window, it will not be shifted anywhere.

Production of wooden windows with their own hands means using special tools. They are not so many:

- a circular saw;

- electric choke;

- manual milling machine on which wooden surfaces are treated.

If necessary, these tools can be replaced:

- hacksaw;

- chisel;

- cyanka.

But since the main thing in the manufacture of frames is a high-quality and accurate fit, it is better to purchase a good tool.

After all the necessary tools are ready for the manufacture of a wooden window with their own hands, you need to make measurements and make good drawings. Having a drawing, it is very easy to calculate how much material is needed. And then already start directly to the manufacture of the box.

Manufacture of a wooden box

For the manufacture of a wooden box, a pine is usually used - this is one of the most affordable and inexpensive materials. Alternative pine is oak, but it is too expensive, and usually make a window of cheaper materials on your own. The window box board needs to dry well, look so that there are no bitch, cracks and other deformations on it. It should also be borne in mind that the box fixed in the doorway will be the main load. The board must be the size of 150x50 mm.

To make a wooden box you need:

- In the workpiece of the box to make a groove, the depth of which is 15 mm, and the form - the letter G.

- Connect four parts (sides) of the block between themselves with carbon black glue.

- Drill holes in the sides of the block and insert a wooden rod, the length of which is 30 mm. Thus, the boards will be securely fixed at right angles.

- Drill in the wall where the box will be mounted, holes, drive the dowel, insert the box and secure with the help of self-tapping screws.

- All the gaps that were formed between the wall and blocks should be pouring the mounting foam.

A feature of such an attachment of the window box is that the board is mounted without taking into account its mobility from the temperature drop.

Making a window frame

For the manufacture of the window frame, you need to take a bar, the dimensions of which depend on the design of the window. In the standard it is 60x40 mm. The profile shape determines the number of glasses, thickness, the size of the stroke. There are two rectangular grooves in a single-global profile: one for glass, and the second is to install in the box. If a double-decker profile, then it has one more groove for the second glass. Profile shapes using a mill or electruruck. The glass must be chosen with a thickness of 4 mm, and the stroke - 10 cm.

To assemble the frame from the prepared boards, you need to cut them strictly in size and at the edges of the formation, at an angle of 45º. With the help of self-samples, the profile gives additional immobility, but the caps need to be twisted so that they drown in the wood.

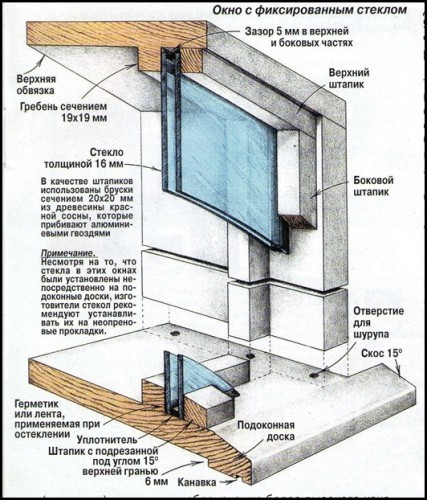

Glazing

In order for glass to accurately farewell and did not pass through it, it is necessary to calculate its dimensions correctly. Mereks need to be removed up to a millimeter. The cutting of glass is performed by a diamond screw, the edges should polish fine-grained emery paper. When working with glass, safety should be remembered:

- in order not to cut the palms, you need to use working mittens;

- to protect the eyes from glass dust and crumbs, you need to use special glasses.

Preparation and inserting glasses occurs in this way:

- Measure the necessary glass length, applied to the place of the section a ruler that is longer than the glass web.

- Hold the glass cutter along the ruler, move the glass to the edge of the table so that the part you want to cut off hang over the floor.

- Gently pressing with hand, glass should break out exactly on the planned line.

- The finished glass insert into the window frame to try, then remove, apply a sealant to the grooves in the frame and finally insert the glass.

- Top glass fasten the stroke, while holding back and frame, and glass. Strapboard fasten a thin nail. If the strokes are wider, then they need to be secured by thin self-drawing.

- To the windows frame, which consists of two parts, you need to mount a vertical bar with similar grooves. One half of the window should be made separately so that it has a thin frame. It must be attached to the main frame on the mounted loops, then the opening of the sash will turn out. It is necessary to fasten the window handle using self-tapping screws, and the chisel on the vertical bar cut the groove so that the window is closed.

For the final installation, the window must be inserted into the window block and fix in the grooves with the help of screws, they should through the box to enter the wall. You can perform this procedure by mounting gun, it will shoot metal dowels in the wall. The gaps need to fill in the mounting foam, and after it dries, shuffle the wall. Work to finish the installation of low tide and windowsill.

Repair of wooden windows

Despite the fact that today more and more people set plastic windows in their homes, there are still many wooden structures. And over time they need repair:

- Most often in replacement needs a cracked glass. To replace it, you need to remove the window sash, remove neatly strokes and remove the cracked glass. From the groove to remove fragments, dirt, smear. And then you can insert a new glass.

- Often there is such a problem as overcast flights. They are formed from loosening angular mounts. To solve this problem, you need to attach steel corners on each angle. There is another option, but it suggests the full reconstruction of the span. First, you need to remove wooden rods that drive down the corners, then disassemble the frame and clean the grooves. Again to apply glue to wooden rods and collect the whole design again. After the glue is completely dry, the frame needs to be treated with sandpaper, paint the oil and paint.

- Large cracks on the windowsill are removed in this way: clean it from paint and dirt, treated with oil and wait, while it does not dry well. The gap flood the waterproof globe, squeeze the window sill so that the crack is disappeared, and fix in that position, and the glue that gets outwards to be removed immediately. You can fill in a tree insert, putting it on the glue, then sharpen and paint and paint.

Read more, how to make a wooden window, you can look at the video.

Start a discussion ...

Start a discussion ...