If you planned the construction of a bath on your country site or at the cottage, but your budget is extremely limited in order to buy high-quality wood, pay attention to foam blocks. The construction time of construction from this material is much shorter, and the cost of building material is much lower. As part of foam concrete blocks, cement, water and quartz sand, so many respect foam blocks for their environmental friendliness and health care.

Content

Feature material

The non-separating and eternal material - foam block, beyond the years, and in strength it is not inferior to natural stone.

To date, foam concrete blocks are often used in the construction of different objects, including when the bath is erected. The main advantage of this material is its property to accumulate and maintain heat due to high thermal resistance. And during the operation of such a building, it is possible to save up to 30% of heat.

After a rounded log of a foam block, it is in second place at the frequency of use for construction purposes, in addition, on ecology, it is only inferior to a natural tree. This artificial material is easily adjusted and cuts off with ordinary hacksaw, and it is possible to use it not only when the framework structures is erected, but also for interior partitions.

The bath is a room where it is always clean, warm and cozy. In ancient times, such steps were built from logs and precisely such, according to certain people, there must be a real Russian bath. However, the wooden frame for today can do in a decent amount. A decent Wooden replacement is a foam block bath, which are characterized by their increased operational properties.

The solid foundation for such a bath is not needed, because foam blocks are a fairly lightweight material, so during construction it can be limited to the arrangement of a ribbon foundation on a sandy substrate.

Currently, there are many different options for baths from foam blocks that you can see below.

As part of foam concrete blocks, water, sand, cement and protein foaming agent. That is, the basis of this environmentally friendly material is protein. Foam block allows you to build an object or figure of any complexity, for example, without effort to make the triangular circular upper part of the facade, which will be suitable for any angle of inclination of the roof.

The main differences of foam concrete blocks from the tree:

- with a fire, the tree is easily flammable, foam blocks - no;

- over the years, the wooden bath, one way or another, will start rotting, and the bath from foam blocks will remain untouched.

For the construction of a bath, foam concrete material must meet sanitary and hygienic requirements and the degree of hardness. As mentioned above, according to the properties, this material is similar to a stone, and therefore, the walls of foam block in the bath will be durable and stable.

When choosing foam concrete blocks for building a bath, you should pay attention to such parameters:

- hydrophobicity. In the building materials market, there are foam blocks with a special protective coating, only such and it is worth choosing;

- the color of the raw materials should be even and monophonic;

- foam blocks with cracks and phones are a production marriage, so you do not need to buy them.

Advantages and disadvantages of foam blocks

The main advantages of a foam block bath:

- This building material has a volume size and light weight, it greatly reduces the volume of work involved when moving material and construction.

- It retains heat much better than the brick building.

- Relatively inexpensive.

- In addition to the high strength porous concrete is resistant to fire.

- Design of the foam block does not settle, unlike wood.

- The room is ready for use immediately after finishing work.

- Bath made of this material is being built quickly and easily, without assistance.

Disadvantages bath of foam blocks:

- In case of insufficient processing the material it absorbs moisture.

- Inside walls condensate may accumulate, which leads to the formation of fungi.

- Filled with moisture walls of the room in the winter freeze and break. This feature reduces the operating parameters of the foam block many times.

The project baths of foam blocks

In fact, a big difference between professional and amateur draft bath of foam blocks do not have: they both look decent and trustworthy. Despite the fact that the build of the cellular structure of brick is quite simple, small defects can still occur at any stage of construction. And plan the smallest bathhouse can avoid fatal mistakes, which, after some time, may occur.

Construction of the baths of foam blocks began to practice not so long ago, but today this material has already proved itself the quality and durability. All that he needs - is a waterproofing and proper finishing.

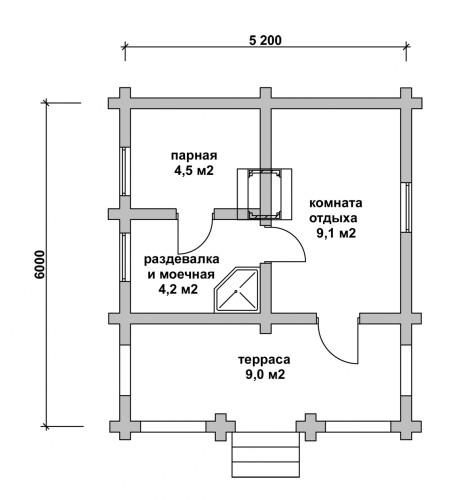

Before you build a bath of foam blocks, it is necessary to consider its individual project. It is possible to reflect most unusual interior fittings, steam, near the arbor and even a small room for billiards. The project is necessary in many respects to intelligently calculate the total amount of supplies, to do the right layout arrangement of window and door openings, as well as other items inside.

Bath of foam blocks with their hands

So, for you need these building materials themselves apart from aerated concrete blocks, such as:

- sand;

- grout;

- concrete;

- fittings, 12 mm thick;

- heat-treated wire for reinforcement;

- timber;

- pipes for sewer arrangement;

- screws, metal corners, nails;

- gofrolist;

- brick;

- polyurethane foam;

- linings for finishing;

- doors and windows;

- thermal insulation materials;

- lamps and electrical wiring;

- antiseptics for the treatment of the walls.

This is the minimum set of necessary construction accessories, which will be useful when erecting the bath with your own hands.

So, we build a bath from foam blocks, and the first point in the work technology will be the construction of the foundation:

- Choosing a suitable place to build, apply the foundation markup according to the project prepared in advance.

- Under the foundation, dig a trench with a depth of 50 cm and a width of 30 cm. It should be exactly and have a rectangular shape. Therefore, do all work on the level.

- In four corners, insert metal vertical stakes. Such a pinway vboat along the perimeter at a distance of 1 m from each other. Horizontally and smoothly wound on them a rope or cord.

- Prepare a frame from existing fittings.

- Concrete pouring can be carried out directly into the ground without an additional formwork. The foundation height should be about 70 cm.

- After that, the concrete must harden for another 1.5 weeks. And then you can proceed to the sewage laying.

- Next, fall asleep the rubble layer over the entire surface, on top of it - a claymzit layer.

- At the layer of clay, lay out the grid, and on top of pour the concrete tie to the level that was determined in advance. The screed thickness should be 15 cm.

- On the finished foundation, lay a layer of rubberoid under foam blocks. It should be remembered that the runner should be slightly laid foam concrete blocks.

Walling:

- Before the construction of a bath from foam blocks, you need to decide in advance, the foam blocks of which brand you will use. The most acceptable option is M25 materials, with dimensions of 100x300x600 mm and D700 density. We need to put such foam blocks on the edge, making the minimum seams so that it does not go warm.

- Put the first row on a sandy cement solution. Rubber hammer align the laying.

- The second, third and subsequent rows of bricks fasten glue for foam concrete.

- Over the doorways lay the blocks on a specially installed beam of wood or metal.

Roof of the future bath:

- A few days after the construction of the walls, proceed to the installation of the roof. The most optimal option is the installation of a row roof with a skate.

- The rafters of one side should be dried in tightening, and the other is to connect to the skate. Corners of the skate depend on the length of the rafted. In the event that the bath will be in an area with frequent precipitation, the angle of the skate should be 60 degrees.

- Configure rafters with tights, perform metal brackets, it will provide them with additional strength. From the chimney of rafters must retreat at least 40 cm, and for their manufacture, choose high-quality wood of the first grade.

- Cutting the roof with boards. Under the ruberoid should be made a double layer of the crate. You can install the rubryoid and subsequently pour the molten bitumen.

- A rough ceiling lay the 2.5 cm thick boards. On it - a layer of foam, which needs to be seen by the same boards.

Heat insulation Baths of foam blocks

Build walls and roof Baths are half of the case. An equally important point is insulation of the construction. At any time of the year, the bath must be warm and cozy, so let's consider the basic insulation options.

- Mineral mats can be asked for the foundation, and under the floor lay a layer of clay and slag. In order not to accumulate moisture inside the foundation, make holes for ventilation.

- Walls are isolated by foil or cotton. It is done between the inner cover and the wall.

- Many heat leaves through the windows, so all sorts of cracks need to be chopped by any non-flammable materials. It is much better if the window openings are two or three glasses, and their form is rectangular and elongated horizontally.

- The doorway should be smaller in order to make a lot of heat from the bath.

- Inside a bath from foam concrete blocks, it is best to sew wood coniferous rocks or to bond with ceramic tiles.

Start a discussion ...

Start a discussion ...