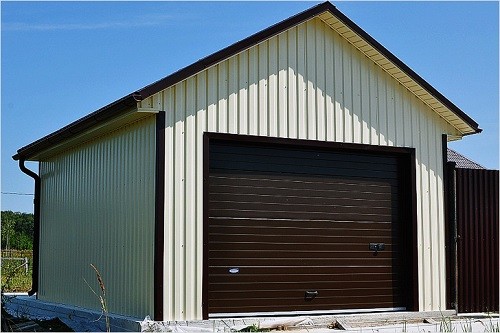

The construction of a garage from the professional flooring with their own hands is the best option for those who want to quickly make a reliable shelter for their car and spend as much money as possible. In addition to the low cost of construction, the garage from the professional flooring has a long service life and can compete with even massive structures from blocks or bricks. In this article you will learn everything about how to make a reliable garage.

Preparatory work

Even people with minimal construction knowledge and skills will be able to build a garage from the professional flooring with their own hands. The profiled sheet has a number of significant advantages compared to other materials. So, given his low cost, it protects the car from wind, dampness and cold is not worse than concrete or brick, especially if you make additional thermal insulation of the room.

The advantages of the garage made from the professional flooring:

- long service life;

- high speed mounting;

- low weight (no expensive foundation is needed);

- low cost;

- good aesthetic indicators (professional flooring does not require finishing finishes, you can pick up a color for every taste);

- reliable protection against precipitation.

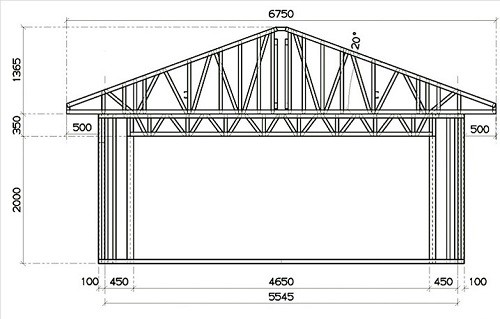

Garage scheme

Before you begin to build something, you need to create a visual scheme on paper or in a computer. Calculate the dimensions of the future garage to determine the amount of profiled sheet.

The standard passenger car in width reaches from 1.7 m to 2 m, and in length - from 3m to 4 m. However, when designing, it should be borne in mind that the garage should accommodate not only the car. There should be enough space to get around the car around, freely open the doors, put a wardrobe for various tools, stock, oils, etc. Often the garage is used and for storing all the things that did not fit at home, for example, bicycle, various equipment, cans, furniture, etc.

If you plan to make a viewing pit, consider the soil characteristics and the necessary depth. The optimal size for the garage is 4x6 m with a height of 2.5 m. Also in the wall must be at least one window to reduce the cost of electricity and provide natural lighting during the daytime.

Choosing a place

When the garage drawing is finished, you can move to the immediate work "in the field". It is very important to choose the right place of construction. It is desirable that this was a flat place near the entrance gate to the site and located behind or on the side of the house. If there will be large trees with shady crowns around the garage, in the summer, the professional flooring will not be very hot from the sun.

Take into account that you have to make an access road to a garage, so as not to breed dirt during the rains and not spoil the surrounding landscape. Therefore, the closer the construction will be located to the gate, the less strength and funds will have to spend on laying the track. It is also recommended to make it direct to make it easier and speed up entry into the garage. The optimal location is 4-5 m from the gate (so you can quickly put the car inside and freely open the swollen gate).

From a residential building, the garage should be located in 5-7 m. This distance is enough to quickly get to the car and not distract the noise of the jilts, leaving for work early in the morning.

Choose a place located at the highest point of the site, but in no case in a lowland, otherwise, during precipitation and melting of snow, water will accumulate, sweeps the soil, and the foundation "floats".

Important: Under the garage there should be no communications (sewage, gas pipes, wires, etc.), especially if you plan to build a loving pit.

Tools and materials

When you attached the dimensions of the future building, you can start creating the estimates.

Tools and materials that will be needed for construction:

- profiled sheets - when counting the number of sheets, consider that during installation they will need to put the brass of about 20 cm, so buy material with a margin (from residues can then be done visors or to put on other economic needs);

- metal profile pipes for montage of the garage frame;

- vapor insulation film;

- fasteners;

- P-shaped profile;

- cement;

- crushed stone;

- sand;

- insulation (mineral wool, expanded polystyrene, foam);

- screwdriver;

- building level;

- plumb;

- shovel;

- metal nippers;

- rivets;

- screws.

Construction of garage

In order to know how to build a garage from a professional flooring, it is absolutely not necessary to have professional skills, just adhere to a clear instruction. It is possible to build a shelter for a car in just a few days if you completely devote yourself to this case.

Foundation for garage

For a garage from the professional flooring, it is not necessary to lay a heavy and expensive foundation, but a certain preparation of the ground is still required. Clean the land from garbage, weeds and remove the fertile soil layer (DERD) with a thickness of 10 cm. If you plan to make a viewing pit, dig up the desired size, swipe waterproofing and facing. Pay attention to the fact that for those cases when groundwater runs shallow, it is necessary to do drainage, otherwise the pit will be periodically filled with water.

Make marking on Earth, knocking the pegs and pulling the twine between them. Over all angles, dig a square shape of 50x50 cm to a depth of about 50 cm. Install on the walls of the formwork and pour the holes with a concrete mixture by placing the reinforcement to the center for an increase in the fortress. To prepare a cement solution, mix the sand and cement in a 1: 3 ratio and dilute with water until the consistency of thick sour cream is obtained.

Continue further work follows only after a complete drying of the foundation. It will take from 1.5 to 2 weeks depending on climatic conditions.

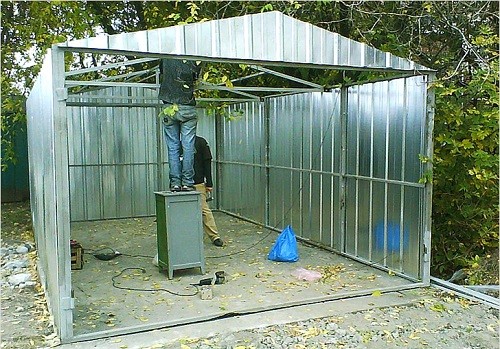

Carcass for garage

For the construction of a carcass of a garage from a professional flooring, metallic galvanized circular profiles of round or square sections are used. They do not rust, and therefore serve for a long time and no complaints.

Facilities for mounting a frame:

- Set vertical racks. The easiest way of fixing is the installation of pipes in the pre-dug holes and the subsequent belling of the sandy-gravel mixture. For a more reliable installation of the pit, pour concrete and wait for its complete drying.

- At the vertical stands, attach the transverse profiles using metal screws. It is recommended to make 4 crossbars from three sides.

- Secure the longitudinal profiles from above, to then install the corrugated flooring on the roof of the garage.

Garage walls

The walls of the professional flooring are attached to a fully assembled and reliably fixed frame. The principle of operation is very simple - it is necessary to attach profiled sheets to the racks screws, fixing the joints with special steel rivets for greater reliability.

Features of wall mounting:

- Before installing sheets, make sure that all the corners of the frame are 90 degrees, and all its racks and planks are strictly parallel or perpendicular to the ground. This will depend on this, the neat appearance of the finished facility will depend.

- Perform sheets of sheets, taking into account the reserve on the laying of the brass 20-30 cm.

- Sewing the wall with sheets and, if necessary, put hydro and thermal insulation materials. For thermal insulation, the garage from the professional flooring is perfectly suitable for inexpensive and efficient material - mineral wool in the stoves.

- Fix the sheets on the lower deficits through the wave, using and rivets, and screws for greater strength (vulnerable place).

- When installing, it is recommended to use various sealing gaskets and bitumen sealants so that the design is refined and completely waterproof.

Roof garage

As for the installation of the roof, it is better to make duplex or single garages from the professional flooring. The duplex option is suitable for those cases when the garage costs separately from the residential building. A single roof can be a continuation of the main roof of the house if the garage is made in the form of an extension. However, if you wish or in order to save time and funds, you can make a single roof for a separate garage.

Roof mounting features:

- Choose corrugated sheets of such dimensions, that they completely cover the roof. If you can not pick up a single large sheet, reduce their number to a minimum in order to avoid extra work capacity and dock.

- Place the sheets overlap and attach to the prepared crate with screws.

- The joints, as is the case with the walls, thoroughly secure the studs. For greater reliability, you can walk sealant.

- If you warm up you walls of the garage, and the roof must be covered with mineral wool and lay a vapor barrier, otherwise all the heat stored by walls, will rise up and go through a cold roof.

Important: the distance between the longitudinal members of the roof batten should be about 1.5 m If you do waterproofing, it must be laid directly on the crate, then put a layer of insulation material, and only as a last resort - profiled.. To fix this roof, you will need screws at least 8 pieces of 4.8 mm in length. per sq. m.

garage gate

The last made the gate. Their design can be any, depending on your preferences and financial capabilities. The easiest option - hinged gates from the same sheeting.

Proceedings:

- Make the doorway of the garage of the profiles with a square cross-section.

- Construct two identical shutters, reinforcing their crossmembers.

- If desired, take in one of the door wings.

- Secure the loop and hang them on the door wing.

Interior decoration

As for the interior decoration of garage space, it depends on the preferences of the owner and the works he will perform within. So, if the garage will be used only to protect the machine from the elements, and you can do without finishing. If you plan to spend hours to sort out the engines, body painting, working with oils and spare parts, care should be taken to make you comfortable.

Tips for interior decoration of the garage:

- Do not use materials that strongly absorb odors, such as wallpaper, or wood. The garage will always loom specific scents, so finish very quickly propahnet.

- Wood for the walls, floor and ceiling is better not to use at all, because it increases the risk of fire hazard.

- Modest and inexpensive option - decoration by plastic clapboard. It is easily clean, undemanding in circulation, it is easily mounted, and if necessary, you can replace a separate segment. The disadvantage is very fragile, so if you accidentally get the car wall, it will inevitably crack.

- Take the place to install a simple open rack with a large number of shelves - it will be useful for storing car care products.

- Plaster is one of the most suitable materials for the internal trim of the garage. It does not absorb smells, it is easy to wash, durable and non-combustible. However, for its application, walls should be prepared - close the heat insulation by sheets of OSB or plasterboard.

Paul garage

One of the most difficult issues in the construction of the garage is the choice of flooring. What makes the floor in the garage, so that he serve for a long time, withstand the weight of the car, did not absorb randomly shed chemicals and looked decently?

What is better to make the floor in the garage:

- Concrete - To pour the concrete floor in the garage, you should pre-make a sandy pillow with a layer at least 10 cm. To eliminate the possible deformation, put a damper tape around the perimeter. Failure sand, watering with water, put a layer of waterproofing and reinforcement grid. Only after that you can pour a concrete solution and align the floor. Such a surface is dry about 3 weeks. Despite the high strength and immunity to burning, the concrete floor forms too much dust, it absorbs chemicals and, accordingly, specific odors.

- Painted concrete is the most popular type of finish during the construction of garages with their own hands. The principle of creating such a coating is described in the previous paragraph, however, after the concrete drying, it is covered with a layer of sealant or paint. It does not give to form dust, absorbed chemicals and smells. Thus, all the shortcomings of the usual concrete floor are neutralized. It is easy and nice to come in such a garage. The protective coating not only increases the operational period of the floor, but also gives it a more aesthetic appearance. The cost of sealant or paint is low, and the protection is very simple even alone - roller, brush or sprayer.

- Self-leveling floor is one of the most aesthetically attractive options for creating a conventional concrete coating. The composition of the bulk mixtures includes two components: a polymer resin and hardener. They give a completely even and smooth coating, resistant to mechanical damage, the effects of low temperature, chemicals and smells. To create a durable and durable floor, a coating thickness is required not less than 5 mm.

- Ceramic tile - for facing the floor in the garage from the professional flooring (photo), not every ceramic tile will be suitable. For this purpose, it is necessary to find porcelain stoneware, clinker or thick floor tiles.

- PVC plates - PVC models are made of very durable polyvinyl chloride, resistant to chemical impacts. Such a floor is distinguished by frost resistance, withstands heavy loads, does not slide even in frost or excessive humidity. You can safely wash the car in the garage, without fearing slipping.

Installation of PVC plates in the garage from the professional flooring (video):

PVC plates well absorb vibration and resistant to shock. Mount them easily even without special skills. The only thing to do is to be aligned and clean the concrete floor. You do not even need to use glue - each element is equipped with a special locking system, thanks to which the floor is assembled, like a constructor. Even younger family members can take part in this work. One of the main advantages of sex from PVC plates - if necessary, it can be disassembled and mounted elsewhere, for example, to make a track on the street or replace some part.

We hope this article helped you figure out how to make a garage from a professional flooring. As you have already managed to make sure there is nothing complicated in this, it is enough just to purchase suitable materials and allocate some free time.

Start a discussion ...

Start a discussion ...