The foundation wall blocks, short-called FBS, are today considered accessible and relatively inexpensive building materials. Thanks to a democratic price, a large assortment and good performance characteristics, such blocks are widely used by many construction companies. In this article we will talk about the pros and cons of the foundation from the FBS, as well as consider in detail the process of its laying.

Benefits of foundation wall blocks

It is worth noting that this material has a number of positive qualities. Among them can be allocated:

- The ability to withstand strong frosts and sharp temperature differences. In the production of blocks into the solution, special additives are added making this material by frost-resistant. Due to such a feature, the foundation of buildings can be erected in the regions with a harsh climate, where heavy cold and large temperature differences are often there.

- Resistance to the effects of aggressive chemicals. This quality allows you to lay the foundation from the FBS blocks in any soils, including in soils with increased acidity. It should be noted that soils in many regions of Russia have a similar drawback.

- Strength and reliability.

- Affordable price.

- Resistance to mold, damage to fungi and insects.

- The wide range is another advantage of the FBS. To date, the Ruby plants produce plates of various dimensions, shapes and compositions. This allows potential buyers to choose the most appropriate option to implement a particular construction project.

Photo of foundations from the FBS:

Disadvantages of material

We listed the main advantages of this building material, now let's touch its minuses:

- We noted that the foundation from the FBS plates will cost you relatively inexpensively, but, despite this, a similar base of the monolithic type will cost about a third cheaper. The fact is that the technology of laying wall foundation blocks, especially if they have large dimensions, will require the involvement of special construction equipment, and these are additional financial expenses.

- Another minus of this design is that the FDBS team will inevitably have seams inevitably. If you do not extract the resulting clearances - the foundation of the house will gradually collapse and over time will come to complete dissent. Through such seams in the house will penetrate dampness and cold, so you will have to spend additional funds, time and strength on the laying of high-quality waterproofing and insulation.

- If you compare the strength of the foundation from the FBS and the monolithic concrete structure, the last option will be in some extent reliable than the first.

Types of foundations from the FBS

To date, two types of structures can be created from such a building material, let's consider them in more detail:

- Foundation columnated - this option is considered rather economical. As a rule, such a base is erected during the construction of baths or panel houses. The columnar design is not suitable for acidic or sandy soils, as well as for soils with a great depth of freezing.

- The tape foundation from the FBS is most often paved before the construction of small houses having a relatively low weight. Such a basis, for example, is suitable for the construction of a dacha cottage or a wooden church.

Construction of the foundation from the FBS with their own hands

Selection of material

The foundation wall blocks are manufactured in various sizes and, as a rule, are used in the construction of a belt base. So that your building was built qualitatively and served you for many years, it is necessary, first of all, to correctly make a foundation from the FBS blocks. To this end, you can use the appropriate computer programs where you should enter all the necessary parameters of the future design and make block layouts - this will allow you to see you in advance how separate items will be attached to each other. Having determined the amount of material and its dimensions, make an order in the store. At the same time, agree on the delivery of goods to the construction site, as well as order a lifting crane that will help you in laying the foundation from FBS blocks.

By making calculation in a computer program, determine in advance where you will have communication. In these places, the plates must be the corresponding holes, their presence can be stated in the order.

Preparation of a place under the foundation

By creating a foundation project from the FBS, to start, depict the construction site in the form of a schematic pattern, mark the place where the lifting crane and other technique will be placed. Next, we will look at the preparation of the place under the foundation in the form of a sequence of actions:

- Using the excavator, remove the top layer from the soil, leave the ground nearby - it can come in handy for reverse swelling.

- In the resulting pit, tick the axis of future walls, using a peg and fishing line for this.

- Making the inner drainage of the base in this case is optional. With subsequent construction, you will need to simply water the walls and floor of the building.

Creating a sole

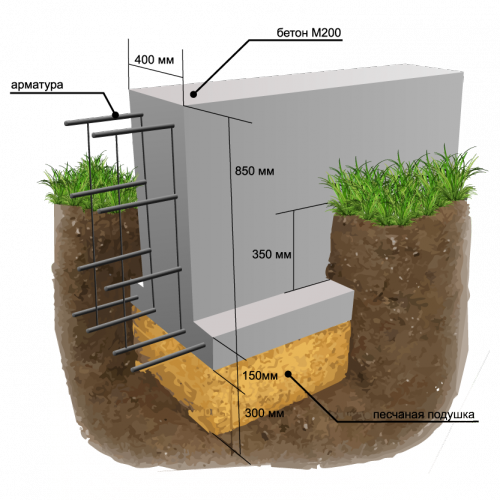

The technology of laying the foundation from the FBS involves the construction of a special sole. It can be a concrete pillow or a lighter design of reinforcement, sand and rubble. Consider the last option in more detail:

- Prepare a sufficient number of reinforcement, as well as about one sand machine and rubble 20-40 fractions.

- In the dug pit, mark the soles, dig around the perimeter of the foundation trench and thoroughly align its walls.

- Put the sand on the bottom of the trench, moisturize it well and confuse.

- Then, put a layer of rubble on top of the sand and confuse again.

- Only after that you can create formwork and knit fittings.

Construction of formwork

The next step in the foundation device from the FBS is to create a formwork. It is done as follows:

- For this design, you will need a cutting board with a thickness of 25 mm. It is installed vertically throughout the perimeter of the foundation, necessarily aligning with the help of hydroevum. The cord is tensioning inside the design, which will subsequently be checked by the level of the flooded solution.

- Then the framework of fittings is installed in the formwork, it is best to use the material of the F12 brand for this purpose.

- When you board the reinforced belt concrete solution, construction work will need to suspend at least 2 weeks. The standard dimensions of the reinforced belt are 20 cm in thickness and 30 cm in width.

Pill pillow and block installation

The base for the base of the house is filled with the help of the so-called mixer or concrete mixer. After completing the work, the concrete is covered with a film and leave a week, periodically moisturizing. After about 7 days, the pillow will completely freeze, after which it will be possible to start the foundation from the FBS blocks. For this work, you will need to hire a lifting crane that will raise the design elements and install them in the right place. In the installation process, the masonry solution of the M100 brand is best.

Waterproofing foundation

The shut-off stage in creating the base of the house is the waterproofing of the foundation. It can be performed using various rolled or coating materials. Many builders consider special mastic as the most convenient option, since it is easiest to work with her. If the house is built in the region where frequent precipitation is considered the norm, you can additionally place waterproofing directly under the FBS blocks.

Foundation from FBS blocks, video:

Start a discussion ...

Start a discussion ...