After buying the site, we thought about the construction of an inexpensive eco-friendly house.

After buying the site, we thought about the construction of an inexpensive eco-friendly house.

Having studied the information on this topic, they decided to use a lightweight saman for construction. This material is a mixture of straw (90% by volume) with clay (10%) - it seemed to us the most suitable for the future at home.

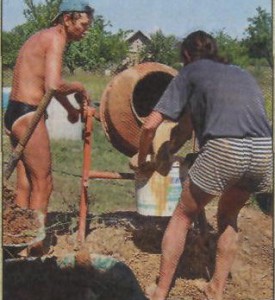

In May 2006, we made a finely blurred belt foundation for the house with an area of \u200b\u200b7 × 6 sq. M., having mastered the thick reinforcement rods to which the strapping subsequently was fixed. Since an easy saming wall in our climate should be a thickness of at least 30 cm, the strapping was made from a bar with a cross-sectional area of \u200b\u200b200x 200 mm, thereby providing the wall with the necessary support area.

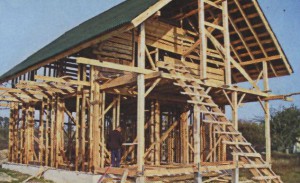

The frame for a helical house is needed special. Corner racks We made from the board with a cross section of 50 × 150 mm, and between them at a distance of 40-50 cm, the additional vertical "stiffness edges" in the form of "ladies" was sewed from each other. Make them was easy. For this boards, 50 × 150 mm we saw on the machine in half, getting a cross section of 50 × 75 mm. After that, putting them on the ground, the "steps" -20-centimeter segments of the timber section of 50 × 50 mm were nailed. And then they installed the "ladents" on the frame, fixing the corners and screws. Additionally, the housework of the house was reinforced by coloring from a bar with a cross section of 100 × 100 mm. Of course, all wooden details were carefully treated with an antiseptic. The upper strapping was made of the same bar, lifting it up using the blocks of blocks (polyspaster). The roof was tightened with a waterproofing membrane, covered ondulin.

The frame for a helical house is needed special. Corner racks We made from the board with a cross section of 50 × 150 mm, and between them at a distance of 40-50 cm, the additional vertical "stiffness edges" in the form of "ladies" was sewed from each other. Make them was easy. For this boards, 50 × 150 mm we saw on the machine in half, getting a cross section of 50 × 75 mm. After that, putting them on the ground, the "steps" -20-centimeter segments of the timber section of 50 × 50 mm were nailed. And then they installed the "ladents" on the frame, fixing the corners and screws. Additionally, the housework of the house was reinforced by coloring from a bar with a cross section of 100 × 100 mm. Of course, all wooden details were carefully treated with an antiseptic. The upper strapping was made of the same bar, lifting it up using the blocks of blocks (polyspaster). The roof was tightened with a waterproofing membrane, covered ondulin.

And then the work stopped: I could not find a good last year's straw, I had to wait for a new crop. At the end of July, the straw we all bought -10 big rolls. From several boards, sewing them with screws to the frame columns, made a sliding formwork. Solla, before laying it into the walls, it was necessary to clean in a clay solution. To do this, it was necessary to lean some kind of door frame from the board. They laid it on. The overseas, was stamped by a banner (film with advertising stretching) and poured into the resulting deepening of the clay solution. It turned out improvised trough. The optimal concentration of the solution was determined as follows: loose into a live hand, and if it was covered with a thin layer of lucid liquid clay, it means that can be soaked and straw. The spruce straw was laid into the formwork, straightening all the lumps to dry out, the straws stick through, forming a monolithic wall. We raged the wall and hands, and legs, and cut from birch logs with a diameter of 6-8 cm with beater. During the day the wall "grown up" by about 40-50 cm, but when friends came to visit us, the process accelerated significantly. Another day after the breakdown, the saman acquired the necessary strength, and the formwork was gradually rearranged higher and higher.

And then the work stopped: I could not find a good last year's straw, I had to wait for a new crop. At the end of July, the straw we all bought -10 big rolls. From several boards, sewing them with screws to the frame columns, made a sliding formwork. Solla, before laying it into the walls, it was necessary to clean in a clay solution. To do this, it was necessary to lean some kind of door frame from the board. They laid it on. The overseas, was stamped by a banner (film with advertising stretching) and poured into the resulting deepening of the clay solution. It turned out improvised trough. The optimal concentration of the solution was determined as follows: loose into a live hand, and if it was covered with a thin layer of lucid liquid clay, it means that can be soaked and straw. The spruce straw was laid into the formwork, straightening all the lumps to dry out, the straws stick through, forming a monolithic wall. We raged the wall and hands, and legs, and cut from birch logs with a diameter of 6-8 cm with beater. During the day the wall "grown up" by about 40-50 cm, but when friends came to visit us, the process accelerated significantly. Another day after the breakdown, the saman acquired the necessary strength, and the formwork was gradually rearranged higher and higher.

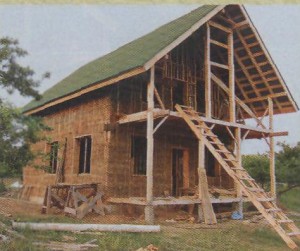

The common efforts of four people in two weeks of non-spiritual labor walls were brought under the roof. So that they quickly dried, the formwork was removed on both sides, and outside the walls were covered with a small metal grid (from mice). To protect against the starting rains, the wall was sewn with waterproof plywood, leaving the so-called ventilated facade. That is, it was sewn with a thickness of 1.5-2 cm to visible outside the Brukes, and already fed to them. In good weather, the wall opened to all winds dries in 1-1.5 months, but in our case it was not necessary to expect mercies from nature. Therefore, inside the construction installed the stove "Breneran", window and doorways were tightened with polyethylene.

The common efforts of four people in two weeks of non-spiritual labor walls were brought under the roof. So that they quickly dried, the formwork was removed on both sides, and outside the walls were covered with a small metal grid (from mice). To protect against the starting rains, the wall was sewn with waterproof plywood, leaving the so-called ventilated facade. That is, it was sewn with a thickness of 1.5-2 cm to visible outside the Brukes, and already fed to them. In good weather, the wall opened to all winds dries in 1-1.5 months, but in our case it was not necessary to expect mercies from nature. Therefore, inside the construction installed the stove "Breneran", window and doorways were tightened with polyethylene.

The stove was treated well, and thus we managed to quickly dry the walls and the black mold did not appear on them - the real beach drying in the wet conditions of samanny houses. Wall from the inside we dragged the vaporizolation membrane and closed the plywood. And when they were calculated, it turned out that we spent about 50 thousand rubles for the house.

Having lived in a straw house for several years, we revealed it advantages and disadvantages. In particular, the 30-centimeter wall thickness for our climate was still not enough: the past frosty winter had to drown twice a day, otherwise it became cold in the room. But in the house there was no dampness, and smells, say preparing food, quickly disappeared. After all, the straw house "breathes." Yes, and fire, as it is called, not on the teeth of the clay woman: we had a fire at the construction stage, the racks burned, and the straw was only slightly charred.

What advice would like to give those who decide to build a house on the same technology? First, consider where you will take the materials. In particular, clay will need much more than, it seems at first. Therefore, simultaneously with the construction of the house you can dig a pond or well. The clay solution is more convenient to prepare in the concrete mixer, so it makes sense to take equipment for rent or buy from local builders.

Secondly, I advise you to buy a straw in advance and interview home interior. In the spring or early summer, find high-quality, not moldy straw is difficult. If the construction material is worried about the building material, then the house can be erected to the summer heat, and it dries it without any oven. But in this case, the straw must be stored somewhere so that it does not deteriorate. The film does not give full protection against water, so it is best to make some temporary canopy and put bales on the boarding dresses. You can proceed and easier: in the first year to make the foundation and build a frame of the house, the cover of its roof. And inside the unfortunate for the winter to fold the straw, where it will be excellent until spring.

Thirdly, you will need quite a lot of water. And if you will deliver it in the canes or barrels from the nearest reservoir, the construction will delay. So think in advance and the question of water.

Start a discussion ...

Start a discussion ...