The panel sandwich was invented not so long ago, but very quickly took their niche on a construction field. Houses from the sip-panels are gaining more and more popularity, and the reasons for this great set, starting with the fact that the material protects well from the cold, ending with a tremendous small timing of the installation. It is clear that everyone wants to move to one's own accommodation as soon as possible, but the developers sometimes declare unreasonably high prices for their services. The way out of this situation suggests itself - why not build a house from sip-panels with your own hands?

Content |

What is a sip panel: material characteristics

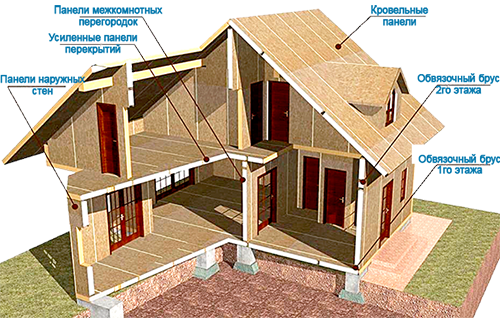

The sip-panels, also known as the sandwich panels, appeared in Europe about 50 years ago, but on the domestic market were relatively recently. The design of them is very simple: between two wooden slabs is a layer of polystyrene foam. It serves as thermal and sound insulation. The thickness of the "filling" varies depending on the purpose of the panels.

The main factors affecting the choice of the thickness of the panels are the type of construction (summer or winter), the type of wall (outer or internal) and climatic conditions of the terrain. On both sides, polystyrene foam is protected by OSB plates made of pressed wood chips.

The panels are attached to each other without lumen, which eliminates the occurrence of cold bridges and increases thermal insulation characteristics. Dense compounds provide special grooves in which wooden swords are inserted. Panels have a standard width of 125 cm, 250 cm and 280 cm.

Advantages of sip panels

Frame houses from sip panels have gained popularity around the world not just like that. This building material has a lot of advantages and advantages over traditional products: bricks, reinforced concrete plates, blocks, etc.

Advantages of sandwich panels:

- Cold protection is a house built from panels, warmer brick about 5 times. Thanks to the special design of the panel, the heat is perfectly held, and the special way of connection does not give cold to penetrate inside the construction. In winter, in such houses is very warm, and in the summer - cool. The material is able to withstand the temperature differences from -50c to + 50c, which makes it possible to use it for the construction of houses even in the conditions of the Far North.

- High strength - the one-piece design of the panels can withstand a vertical load of 10 tons, transverse - 2 tons per quarter. m.

- The construction of the house from the sip panels is much less time than on the construction of buildings from any other building materials. Building an area of \u200b\u200b150 square meters. M can be created for 3 months, which and talk about small private houses. So, install the house of a house of 50 square meters. m You can only 5-6 hours.

- The panel sip is made of environmentally friendly materials that are not dangerous to health people, animals and the environment.

- Durability - with competent finish and installation, a house from the panels is guaranteed not less than 80 years. The polystyrene foam is not subject to rotting and damage to parasites. The worst thing that can happen - wetting and destruction of OSB plates.

- Fire safety - panel sip have 3 degree of fire resistance. This means that they can withstand the effect of direct fire for an hour. In case of fire, the panels do not light up and burning, thanks to special antipyen impregnations. Energy that stands out when burning the panel is 7 times less than the wooden products. If the inner finish of the house of the sip panels contains drywall, the fire comes down to a minimum, since this material has good fire resistance.

- Soundproofing - in a frame house from the panels is always quiet and cozy, since the polystyrene foam inside the walls does not let the air that transfers sound oscillations, and absorbs the sounds up to 70 dB.

- Savings - the construction of a panel house will cost 2 times cheaper than brick. Moreover, we will argue your own private house with an impressive quadrature will be more profitable than buying an apartment in the city. The reasons for such saving set. The very first - under the house from the lights of the panels there is no need to build a powerful expensive foundation. Suggested construction deadlines also play not a latter role. Plus to all, you will not need heavy machinery - the panels easily can be lifted and transferred manually. This list does not end. Since the panels are perfectly kept warm, you can save on heating. Transportation of the material will also cost inexpensively or at all - manufacturers often take the delivery of large batches for themselves.

Disadvantages of sip panels

Unfortunately, to invent impeccable building material, which would not have a single disadvantage, has not yet succeeded. The panel sip is no exception, but its shortcomings can be attributed to the features of exploitation than serious mishaps.

Opponents of the sip panels (yes, there are also such) argue that they are easily ignited and are not suitable for the construction of houses. However, often fires occur inside, and there panel walls are covered with non-flammable plasterboard, therefore the risk that such a building will break up as a match, is minimized.

There is also a legend that in the sip panels like to shave mice and other rodents, but no one has provided actual confirmations. The issue of environmental friendliness is also especially acute, but it comes on no, if you remember that many products (meat, fish, bird, sweets) are often packaged into polystyrene foam containers.

Some argue that the walls from the panels do not protect against noise, but if we take into account the fact that life in a private house eliminates the existence of neighbors behind the walls, from the bottom and on top, then there is no special noise. In addition, the external and interior decoration increase sound-proof characteristics.

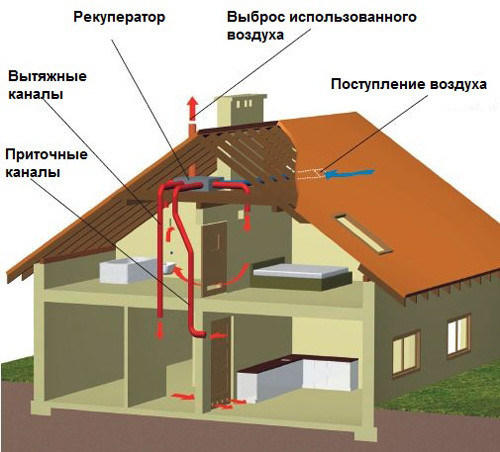

The only truly justified nuance of using a sandwich panel is to improve the ventilation. Since the elements are fitted close to each other, they obtain a completely deaf wall that do not transmit air. For this reason, at the stage of creating a project of houses from the panels, the gasket of the ventilation system is immediately taken into account.

Choosing foundation

As we have already told, for houses from the panels do not need a massive expensive foundation, however, mistakes in organizing this issue are quite common. All because it is necessary to take into account not only the small weight of the house of the house, but also the properties of the soil, the level of groundwater and climatic conditions as a whole.

The optimal options for foundations for houses from the sandwich panels are:

- screw pile;

- columnar;

- ribbon small breed;

- monolithic (reinforced concrete plate).

The main danger in the construction of such houses is lurking in the lateral tangent forces under construction - during the spring of the soil, the foundation may simply go to the surface, and the house is tamed or crawl due to this. Whatever the foundation you choose, its cost will be about 20% of all the costs of construction, which is very much. But in this stage, it is not worth saving at this stage, otherwise the subsequent repair and error correction will take even more money.

Screw piles

The prevailing majority of specialists agree that the frame houses on Canadian technology are best building on the foundation from the screw piles. This is a relatively new way to arrange the base, which is characterized by economy, simplicity and high installation speed compared to the rest. The foundation device on the screw piles is cheaper than any other by 30-40%, even taking into account the fact that you will need to hire the team of professional builders.

The spiral pile is a steel pipe to which the blade of a special configuration is welded. It has a high bearing capacity, because in the process of screwing in the soil, it does not break the soil, but, on the contrary, it seals with its blades. It is incurred deep into the level below the fruit of the soil, which by itself prevents the deformation of the construction of the bright.

The service life of such a foundation can be calculated by centuries (usually the manufacturer gives 100 years). But the main advantage is a ventilated underground, which is very by the way when using the sip panels. In addition, if you ever want to make an extension to the house, you only need to install the desired amount of piles, and the foundation will work as one whole, evenly distributing the overall load.

Fine-breeding foundation

This type of foundation for houses from the panels is used less often and mainly on non-empty and weakly soils. In other cases, he will "go" in the first spring. For arrangement, a fertile layer of soil is removed (about 30-40 cm), formwork with reinforcement and poured all cement mortar.

A small-breeding foundation will easily withstand the weight of the sip panels. For the risk of deformation from uneven soil to minimize, specialists are recommended before the filling of concrete to arrange a gravel-sand pillow.

To increase strength and durability, the foundation is strengthened by the reinforcement framework.

Pouring concrete at once, so for operational work you may need 2-3 people. After the fill, the concrete should be treated with a vibropilet or at least give a stick in several places to eliminate the formation of air emptiness.

The disadvantage of this method is the long period of drying concrete, which can last up to 4 weeks. Also ventilation underground will be not as good as in the case of pile. For this usually make special holes. If you want to make an extension to the house in a few years, it will be quite problematic and troublesome. The laying of all communications (electricity, sewage, water supply) must be organized to the fill of concrete, which is also not very convenient.

Monolithic foundation

If your site is located on a weak bunch of soil, the arrangement of the monolithic foundation will become the only right solution. It is a solid reinforced concrete slab, which evenly distributes the load from the house to the ground and does not allow it to be deformed from seasonal movements.

The principle of the construction of a slab basement is quite simple: remove the fertile layer of the soil, make a drainage pillow from sand and rubble, poured all concrete and strengthen the screed of iron reinforcement.

The only drawback of this type of foundation is a high cost and difficulty with the construction of additional attacks in the future.

Foundation column

Such a foundation can be considered a "relative" of the pile, but the arrangement will take much longer and forces, although its value is lower than that of a monolithic or tape. A columnar foundation is suitable for non-empty and weakly soils.

It consists of a pillars located at the points of intersection of walls, at the corners of the future building, in the location of massive beams, simpleness and at points with a large load (long walls, for example). The bond base excludes the possibility of a basement arrangement, but provides additional ventilation of the underground, as in the case of pile.

The shape of the pillars can be any, but most often they are made round, because such structures are easiest to put in the wells made by a manual brown. Materials also use different: bricks, wood, concrete. Square poles are made of bricks, but they are inconvenient to put on the depth. Therefore, the optimal option is the construction of round concrete pillars, reinforced by reinforcement.

Important: A columnar foundation cannot be laid out on areas with a high level of groundwater, since in this case the base on which the poles will be relying, will be fragile and can be blurred with water.

Installation of panels

We have repeatedly mentioned that the panel sip is very lungs, so for installation you will not need a large construction equipment. In fact, the work is very simple and fast, and if it is better to enlist the support of specialists to build a foundation, then build a house from the sip panels is quite realistic on their own.

Important: Before starting to install, it is necessary to carefully calculate the house from the panels, in order to stock with the necessary materials, including the finish, fasteners, the arrangement of roofing cake. The drawing should display the thickness of carrier and interior walls, the laying of communications, the location of windows and doors.

How is the installation of houses from the panels sip:

- The foundation is placed by waterproofing material (rubberoid, bitumen), and on top of it - a strapping bar, treated with an antiseptic.

- The base boards are attached to the base of the strapping bar, using screws for fasteners.

- Sandwich panels are attached to starting boards, starting with corners of the house. Connect them very simply by inserting the groove in the comb and enhancing the fastening of screws.

- So that the jokes turned out to be sealed and did not let the cold, they are blown by mounting foam. So come with the ends of each panel before docking it on the other.

- If you build a house on a tape foundation (finely breed), starting boards should be attached not to the strapping bruus, but to composite panels. Similarly, it is necessary to connect vertical seams, then with proper processing so you can collect not only walls, but even overlappings and roof. As a result, a design without a single gap, which has high thermal insulation characteristics is obtained. Panel house, unlike wooden, does not give a shrinkage and does not crack like a brick or blocks.

- Since with the assembly of houses from the sip panels, solutions and other wet technologies do not use, this can be done at any time of the year.

- The construction of the roof at such a house is a separate story. You will not need to create a crate to put the materials of the roofing pie, as in all other cases. Moreover, you don't even need to collect the cake itself as such - the sandwich panel itself is impermeable heat-saving protection. The panels are placed on rafters, fixed with self-drawers, and the roofing material is mounted on top. Most often choose metal or bitumen tiles. It is recommended to leave the ventilation gap between it and panels.

- If we are talking about a small design, it is not even necessary to build a rafter system for it - this role is taken on the boll built in the panel.

- The roof can be assembled on Earth, and then lift it entirely and install it in a right place, but it will take a light faucet. Similarly, you can enroll with the walls.

Finishing sip panels

The construction of houses from the sip panels is pleasantly not only fast deadlines for the installation and simplicity of construction - to study the finish of such structures a real pleasure! Since the surface of the panels is perfectly smooth and smooth, you do not have to spend money on plaster or screed and watch the walls, floors and ceilings to achieve the desired result for finishing facing. Consider how it is possible to reflect the frame house outside and how to carry out the inner decoration of the premises.

Finish inside

Before proceeding with the interior decoration, it is necessary to seal the joints with a painting grid, stick and polish them. Since the monolithic panels, immediately think about the communication and make holes for them. In the bathroom, preparation occurs on another scenario - the joints are closed not with a grid, but a sealant based on silicone or acrylic. Panels on the floor should be covered in fully and make the wall on the walls of about 20 cm so that if water is broken, no wet wall materials.

Materials for finishing houses from the sip panels can be used any. The walls are advised to pre-entee plasterboard. This is not so much for the aesthetics (panels and so smooth), how much to strengthen the fire safety of the building (we wrote above).

Since the floors in such houses do not need alignment and insulation, they can be sealing them even with the most whimsal coatings - laminate, tiles, parquet. In the bathroom and in the kitchen it is better to make bulk acrylic floors to make extra waterproofing.

Finish Outside

Some owners prefer and not at all resort to the outer decoration of houses from the sandwich panels - they are already looking pretty beautiful. But to protect the material from dampness, it is recommended to close it with something.

The most popular options for external finishing of panel houses:

- Siding - vinyl siding panels are made of thin plastic. Coloring often imitates natural wood, the surface does not fade, protects well from moisture and is not susceptible to rotting. Socular siding is a bit thick of classic vinyl panels (3 mm) and can be used even for interior decoration. Coloring mimics not only wood, but also natural stone, which allows you to create interesting exteriors. There is also steel and metallic siding. The first is made of galvanized steel and a thin polymer coating. It can withstand strong temperature differences, mechanical effects, direct contact with fire. Metal panels appeared on the market relatively recently. They have all the characteristics of steel, however, the cost is much lower than the galvanized products.

- Facade plaster is the most common version of the exterior trim. Decorative compositions allow you to achieve an interesting effect and protect the panels from the negative effects of the environment.

- Profile, a metal profile is chosen for its high strength, durability, corrosion resistance and simple installation. A wide color palette allows you to choose an option for every taste. A small weight does not create a strong load on the walls and the foundation.

- Fibrocement - plates are made of environmentally friendly materials (90% cement, 10% of cellulose) by pressing. Securely protect the house from the cold, rain and wind, the operating deadlines can be calculated by decades.

- Clinker facade tile - comes home cozy and respectable look. Despite the high cost, it is chosen because of beauty, durability (can last 100 years and longer) and ecology.

- The facade tile is a cheaper option compared to clinker finish. The tile is made of concrete with modifying additives and allows you to create a convincing imitation of natural stone and brickwork.

As described in detail in the video, houses from the sip of panels every year they are becoming increasingly popular. This is explained not so much fashion as a tangible savings - housing is constantly becoming more expensive, apartments in cities are still becoming more and more difficult to find their own housing.

Why spend crazy money on an apartment with a modest quadrature, noisy neighbors and a smoke track outside the window when you can build your spacious and warm house from the panels of panels much cheaper?

Start a discussion ...

Start a discussion ...