The sacred houses are becoming increasingly popular, because it is not only environmentally friendly housing, but also energy saving, and therefore very warm. To date, to build such a house of large financial investments will not be required, due to the cheapness of the necessary building materials. And if desired, Samama can be prepared with their own hands and build a house on their own.

Feature material

Samama is made on the basis of a mixture of clay, straw and sand. In the construction production it is called raw brick. Ceramic brick differs from the samana in the fact that the samanny is dried in air, and ceramic - in the furnaces.

One-story buildings are built from a saman brick, less often - fences, but only in dry climates, as frequent rains destroy the material over time. It is worth noting that Samama is used in construction not one millennium. Even the Great Wall of Wall in its composition has a naughty material.

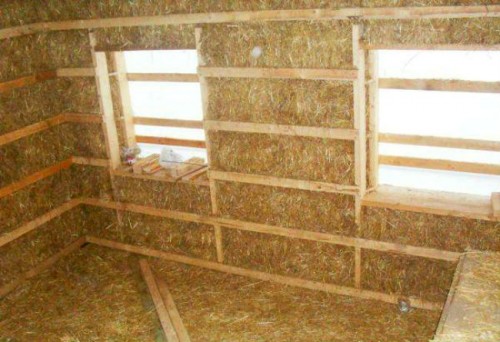

Most often in construction use light Samama. It is dense and durable, does not burn and does not seek. In addition, well maintains his form and most importantly, "breathing". Easy saman is cheap, perfect for filling out a skeleton building, playing the role of insulation. Its components are clay with straw and therefore such an eco-friendly samana and absolutely not toxic.

The lack of a lung self-made is possible mud impurities at the stage of its preparation.

Read more about how the house is like a lung samana in the photo.

The difference between heavy saman from the lung in the fact that, for the construction of a carrier wall, a light self is not applied, since it is too thin, it is most often used to fill the wooden frame building. As part of a heavy samana more clay, because it is suitable for the construction of bearing structures.

Features of houses from Samana

Among the features of saman houses can be allocated:

- Reliability and durability. Prepare a good foundation and a reliable, unconflaking roof for a samanny house, the design can serve more than five hundred years, thereby surviving traditional frame houses. The strength of the saman home provides densely interlaced straw fibers in the material structure.

- Lack of dampness and ability to maintain heat. The wall of the samana has an exemplary thickness of more than 30 centimeters, while having to save and save the heat. In summer, the house of Samana is distinguished by comfortable cool, and in the winter they retain heat.

- Affordable price of Samana. This is a very cheap building material.

- The house from Samana is erected very quickly. In addition, after the construction of a saman frame, it will only be twisted without other additional work.

The benefits of the Samana are:

- Climatic resistance. The ability of saman walls to relax heat when the high temperature of the air is outside the window. To transmit heat or cold 60-centimeter wall, you will need about a day. In winter, with a baked heating of a saman house, his walls are well warmed and about 10 hours remain warm.

- Plasticity and fortress of material. Houses from saman material have high strength. If you maintain a saman home in proper condition, it can stand at about a thousand years.

- Absorption of noise. Samama in its structure does not spend sounds. Therefore, part build samanny houses near roads, railway tracks and factories. The saman walls absorb not only noise from the outside, but also sounds inside the house.

- Samama as a building material is safe for health, does not contain toxic substances.

- It has refractory qualities and is widely used for the manufacture of chimneys.

The disadvantages of the Saman are:

- Weak moisture resistance. The samable walls on the outside require plastering and precipitation protection.

- There are mice in the walls, since it will not be difficult for them to sprinkle.

- It is desirable to build a building in summer and in the spring, since in winter this material is faintly, it is necessary to use alkalis.

- The saman blocks dry long.

Saman is unsuitable in the following conditions:

- designs are not built on steep slopes;

- in the shade of trees;

- in places where floods often occur.

Selection of material for home from Samana

For the construction of the Saman you will need:

- Clay. Pretty clay for the construction of a samanny house is mined outside the city, at the site of ground development, in a career, dug trenches at the place of future construction. Clay must be fatty or medium, in which case it does not scatter. Externally, the clay has red, the color of ocher, gray. But Neurko is gray. In some places you can find the deposits of clay green, white, black and so on. It is necessary to understand it well in order not to make a mistake. Different reservoirs can also find clay, for example, at the bottom of the lake. According to its properties, it is waterproof. To check if you really found clay deposits, take a small lump and mix with water. If it becomes very plastic as plasticine and sticky, it means that it is really clay suitable for forming saman bricks.

- Straw. A dried winter wheat is suitable as a straw. A straw from rye and barley can also be used. Prerequisite - dry straw or hay of coarse herbs.

- Sand. For saman blocks, sand from large particles is used (approximately 1.9-2.1 microns). By its structure, sand should be multifaceted, but not only round. Career sand is well suitable. Sea and river can be used as a last resort.

Planning construction from Samana, it is necessary to prepare clay in the fall:

- In a special pit (bourge), dug out on the street, clay lay out layers. Dimensions of recreation: in - 100cm, d - 200cm, sh - 150 cm.

- Layers of clay laid out, about three meters high, poured with water. Top covers wet straw. Straw is covered with a rubberoid or other coating. Of this amount of clay in the pit, approximately 600 saman blocks, dimensions 2x2x4m.

- In early March, the coating is cleaned with a layer of straw and again covered with a film from polyethylene, creating a greenhouse for clay. Thus, it will not dry and retain their stickiness.

Making saman blocks

For the manufacture of saman blocks, it is necessary:

- First of all, thoroughly mix the clay and sand, adding water and straw. The consistency is thick.

- From the grinding mixture, the ball with dimensions similar to a chicken egg is rolled. Proper consistency is determined as follows: if the ball will too stick to the hands - it means that the sand shoves, if the ball is crumbling - clay is added.

To determine whether the consistency of the composition turned out, it is necessary to dry the ball from the saman composition and drop it to the ground. If he did not crack - it means everything is done correctly.

Technology formation of saman blocks:

- The construction of the house from Samana is starting with the formation of blocks of necessary sizes. To do this, use bottomless boxes of wooden boards, about 25 mm thick.

- Finished forms are pre-wetted with water and sprinkle with small grain waste, the type of sex. Then the finished mixture into blocks will be tamped.

- Dry blocks on drafts. Three days later, they are turned over and pesticing another week. Then placed on the edge of two blocks.

- Brick readiness is determined by its color. Along the block, its color should be the same. It must be solid. To check the shirl block for strength, it is necessary to put it into the water. If during the day he did not dissolve and not sphums - it means it turned out high-quality building material.

Construction of a samanny house

If desired, it is quite realistic to build a house from the Samana with your own hands. It is important only to provide yourself with all tools, such as:

- digging tools - shovel, chip, forks;

- large containers for water and kneading plaster and storage of materials;

- level for surface leveling;

- large strong knife to trim saman;

- pocket knife to cut tarpaulin and other materials;

- wooden sticks for creating holes in saman blocks;

- tools for the transport of materials, the most suitable construction belt;

- barrels of large volumes for water;

- sprayers to spray Samana;

- sieve with dimensions of 1.25, 0.6, 0.3 mm for plaster;

- wooden shovel To mix plaster and blend for overlaps;

- ax, saw;

- watering can or hose with running water;

- stairs, scaffolding, rag for wiping dirt, buckets, gloves, roulette;

- can be useful for plastering;

- scrap, safety glasses, glass cutter, marker for marks, rope.

To build a house from Samana, it is necessary to plan the height of the ceiling in advance, which in a saman house should be done above 30 centimeters, because the saman design is seated over the years.

So that rodents do not make their way into the house, the lower part of the walls should be strengthened with a metal mesh, and all the elements of the tree are treated with antiseptics and waterproof.

The construction technology of the house from Samana:

- Such a building material, like Samam, does not like a wet environment. Therefore, the construction of the house from Samana is better to start in the summer, in dry and warm weather.

- First of all, it is necessary to outline the size of the area under construction. Drop the land for laying the foundation and align under the level.

- At the same time, sewer communications are paved and fill the drenzhem dreament dreamed.

- The foundation must be protected from the wet by fencing the base of the scene. The foundation is made of brick or reinforced concrete. During the construction, the base of the foundation is raised by more than half a meter, and isolate the tone or film. At the same time, its thickness should exceed the thickness of the walls in the future house.

- When laying saman bricks in summer, a solution of sand, clay and straw is used, approximately 4: 3. When laying bricks in spring or autumn, a solution from lime and cement is used.

- In the place of future door and window openings, during brick laying, antiseptic tubes are laid, to which the doors and windows will be attached.

- Doors and windows of the future should be placed, observing the distance of more than one and a half meters from the corners of the house. The thickness of partitions in the house should be at least 60 cm.

- For walls from saman brick, you can use a wooden overlap, for brick and saman walls - reinforced concrete floors.

- During the start of the construction of the walls, you need to make a wooden roof frame, which will be removed when the walls are ready.

- Walls must be vertical or wedge-shaped without convexities.

- After the end of the walls, you can build the attic, beams, overlap.

- When the walls finally fall, and they will need it for about a year, they must be twisted with a lime-clay solution, with the addition of sand and small straw. After applying one layer of plaster, small pegs are driven into the wall, so that the plaster keeps.

- After two layers of finishing, it is necessary to align the walls and paint if necessary.

- The roof of the house can be made of two types: classic and attic. In the classic version there is insulated floor and a cold attic. An attic roof is insulated, a residential premises is equipped under it.

- After completing the roof construction, you need to twist the ceiling.

- From the outside of the wall is also plastered. You can also dye them with ocher.

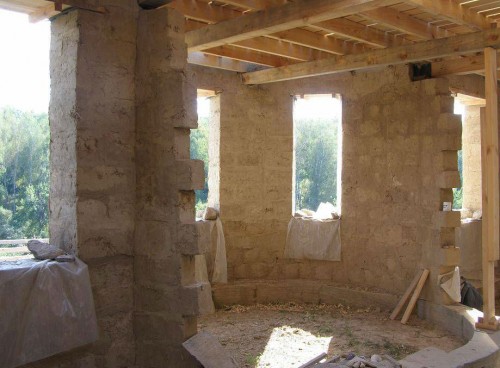

- When it comes to building a house from a light Samana, then a wooden frame of the house is built after laying a foundation. The walls and partitions of the frame are filled with layers of lung samana.

How to build a house from Samana with your own hands in more detail on video.

Start a discussion ...

Start a discussion ...