One of the most important points in the construction of a new house is the correct selection of building materials. From this depends the fortress of structure, its energy efficiency and the aesthetics of the appearance. Although, the last parameter, at first glance, is not very important, it is currently of great importance. About energy efficiency with real energy resources and speak and speak. A properly built house may continue to save a lot of money.

What are ceramzite-concrete blocks?

To build modern houses, a wide range of materials is used:

- Wood.

- Concrete.

- Brick.

- Foam concrete blocks.

- Slag concrete blocks.

- Ceramzite blocks.

It is the last material from this list at the present time acquired the greatest popularity. Due to its structure, the ceramzite has quite good performance properties that at a relatively low cost makes it one of the leaders among builders. The construction technology of ceramzite concrete blocks is practically no different from the specifics of the construction of brick or slag block.

In appearance, such a block is not too different from the gloomy, however, it has differences in composition. As a filler in it instead of a domain slag, clay is used. Ceramzite is small balls that have a spongy structure. Due to this, the weight of the block is significantly reduced in comparison with the same brick, which favorably affects the weight of the structure, reducing the cost of the foundation. In addition, due to the porous filler structure, such blocks have low thermal conductivity and excellent noise insulation, which is quite important for the modern structure. Ease of working with this material allows manufacturers to make blocks of various sizes and configurations both for the construction of external walls and domestic partitions.

The advantages of ceramzite concrete blocks can be attributed:

- Ecology. In comparison with the same domain slag, the ceramzite does not contain impurities harmful to humans, which makes it possible to use it for installation indoors.

- Fire safety. This material has excellent resistance to high temperatures, it is difficult to flammify.

- Resistance to moisture.

- Durability.

- Low thermal conductivity, in comparison with aerated concrete blocks, material from clay has thermal conductivity almost 1.5 times lower.

- Good noise insulation.

- High performance when installing. Thanks to an excellent weight ratio and size, such blocks are quite easily mounted, reducing the time for the construction of the house.

However, it is worth noting that with all its advantages, such a building material is not deprived of the shortcomings. Among them:

- Mandatory presence of finishing of external and inland walls. If you leave such a house without external finishing works for more than 1-2 years, then the strength of the ceramzite concrete will noticeably decrease that it will negatively affect the rigidity of the structure.

- This material cannot be used to build buildings foundations. Its density does not allow it to withstand strong mechanical loads.

- Due to its lightness and large dimensions, the cost of shipping costs increase. However, it is worth noting that this negative effect is important only for large volumes of construction.

Calculation of the required amount of material

The first thing for the construction of the house from the ceramzite concrete blocks it is necessary to clearly calculate the amount of material. Sell \u200b\u200bunnecessary parts after the end of the work can be only with a big discount, and this is extra costs.

Make the calculation of the ceramzit concrete blocks on the house is very simple. You need drawings of the built building and the specification for purchased blocks. As a rule, manufacturers use the standard size of the produced block, which is 190 mm x190 mm x360 mm for the outer walls and 190 mm x90 (120) mm x360 mm for interior partitions. Considering the area of \u200b\u200ball walls, the thickness of the masonry and the size of the blocks, you can calculate their number. This number is multiplied by 1.2 (20% leave in case of battle or damage) and the resulting quantity boldly buy.

When buying clay blocks, you need to pay close attention to their quality:

- The seller must necessarily show the product quality certificate. It should contain standards according to which blocks are made.

- Learn the conditions for the production of blocks. Made in the neighboring garage of dubious raw materials, on homemade equipment and unqualified workers - it is better not to take.

- Check out the overall dimensions. Selected in random few blocks from the proposed batch should not be different sizes.

- Check the geometry of the blocks. The surface of the side faces should not have irregularities.

To build a one-storey house of ceramzite-concrete blocks, it will be enough to use full-scale elements. If the house is 2 or more of the floor, in order to avoid excessive pressure on its foundation, it is better to use multiple blocks. Their feature is that from the ends they have special docking grooves that allow you to connect blocks from the ends without the use of the solution.

Foundation arrangement

The construction of the foundation is one of the fundamental work in the construction of any home, including construction from clay blocks. The scheme of the establishment of the foundation depends on whether the construction of the technical floor is foreseen or not. In the case of the basement planning, in which it will be possible to place the boiler room, technical floor, laundry or gym, the basis is equipped from concrete blocks. If the basement device is not planned, the foundation is made with a belt, along the perimeter of bearing walls. To do this, the trench of a depth of no more than 50 cm and the width of the width of the wall is +100 mm.

The bottom of the trench is put a sand pillow. Then the chipboard or OSB shields make formwork and reinforcement grille. It is needed for a bunch of concrete so that it does not crack under the weight of the walls. Armature, as a rule, is associated with the help of knitting wire. After laying a reinforcement mesh, a concrete solution is poured, which is prepared on the basis of a mixture of cement of the grade 400 and discravan. The ratio of cement and dropping should be 1: 3. Every 15-20 cm layer of concrete seal a special tool.

Frozening concrete depending on weather conditions can stretch from 2 to 4 days. The slower this process will occur, the stronger will be the foundation. Therefore, in the construction of the house, foundation works are trying to spend about April. The fact is that the prepared basis for 12 weeks will give a shrinkage and build on it at this time is not desirable. After removal of formwork, the foundation is covered with a waterproofing layer. To do this, you can use mastic or molten resin. The gap between the foundation and the soil is filled with sand.

Construction of a house of ceramzit concrete blocks

Procedure for installation work:

- After shrinkage of the foundation, its surface can be a curve, so before starting laying it must be aligned with a solution. The surface of the surface is verified using a level.

- After pouring the solution to the surface of the foundation, 2-3 layers of rubberoid are laid, which will serve as waterproofing. Between the layers put the layer of mastic.

- Stop blocks start from the corner. It is necessary to do this by stretched between the corners of the building with a shoela.

- First, the first row is stacked throughout the perimeter, then the second. As often as possible, it is necessary to control the correctness of the masonry using the level and plumb. The fact is that blocks in their geometry can have a taper, which can lead to the curvature of the walls.

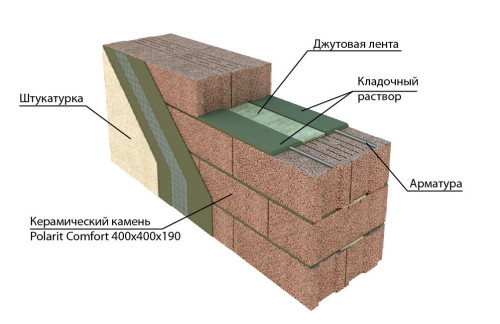

- After laying 3-4 series of blocks, the wall reinforced with fittings. To do this, the metal rods are placed on the perimeter of the walls, which are layered and the next number of blocks.

- When erecting double walls, two rows of blocks are placed simultaneously by tying them between themselves. For installation of blocks, a conventional cement-sandy solution is used, which are labeled the lower and side parts of the unit.

- If the construction of a two-story house is planned, the thickness of the walls of the first floor must be at least 400 mm. For this, two rows of blocks are placed or blocks of large thickness. Some manufacturers for multi-storey buildings produce similar materials of 590 mm x400 mm x200 mm.

After the construction of the walls of the first floor of the building, the upper layer of blocks is strengthened by the reinforcing belt. It is done for a more uniform distribution of the load on blocks from the overlap or walls of the second floor. Perform such a belt from full-scale brick or reinforced concrete blocks. The reinforcement belt must necessarily be insulated, since a complete brick or concrete thermal conductivity is much higher than that of claying blocks.

Exterior decoration of walls when building a house from clay blocks

For better thermal insulation of walls from ceramzite-concrete blocks, several facades are used:

- The simplest and cheap warming option is the facade of polystyrene foam blocks. Such plates have a thickness of up to 50 cm and will be able to warm the house quite efficiently. They are stacked on a special solution on the surface of the wall and are fixed by dowels. Then the layer of reinforcement grid is mounted, to which polymer cement is applied. Decorative plaster or facing tile is applied to its surface.

- So-called ventilated facades using mineral wool are also very popular. Installation of such a facade is a rather complicated and cost. The first thing to the surface of the wall of the ceramzitobetone is stacked by a layer of vaporizolation. To do this, you can use aluminum foil. Then the guides to which mineral wool is mounted, a layer of waterproofing and an external finish are mounted: siding or aluminum panels. This option of the facade is more durable and has the best thermal insulation properties.

Start a discussion ...

Start a discussion ...