Four-tight roof, otherwise, called Valmova, has long been and universally used in European countries. Currently, an increasing number of country house owners in Russia prefer this durable and reliable roofing system.

Content

- Types of four-tight roofs

- Advantages and disadvantages of a four-page roof

- Calculation of the fourth roof

- Materials for the construction of a four-page roof

- How to create a four-page roof project

- How to calculate the load on the rafter system

- Installation of a four-page roof with your own hands

- Four-sheet roof: video

- Four-sheet roof: photo

Types of four-tight roofs

The most important distinction of the hip roof is that its design does not imply the frontal. Instead, there are 2 extra skate.

- a classic four-tight roof (all overheads are at one height, all four slots with straight rafters, and corner ribs originate from the central skate);

- tent roof (angular ribs of the ribs diverge from one point in the center of the roof, there is no skating run in its design);

- danish roof (suggests short raids in the top of the roof with frontones, which are used for lighting and ventilation);

- the semi-haired roof (with the stretch can be attributed to the four-page roofs, because its design is more reminiscent of two-tie - the rafter legs are parallel to each other and installed on the long side, rest on Mauerlat);

- the broken roof (mansard) corresponds to its name, and has a set of broken lines in the design, which allows you to build a higher ceiling on the additional floor and the use of living space is maximized;

- the multi-sking hip roof (despite the fact that the number of rods is more than 4, the principle of assembling the rafter systems of this one of the most difficult varieties does not differ from the construction of a simple four-sheet roof).

Advantages and disadvantages of a four-page roof

Any roof has strengths and weaknesses in their design. And the four-sheet roof configuration is no exception, and its advantages and disadvantages are considered, usually, in comparison with the two-tie - the most common and simple roof option.

Benefits include:

- the correctly designed roof is well opposed to the winds of even hurricane strength;

- little is subject to the destruction of the roof in those places where there are eaves;

- thanks to the rigid design (due to angular ribs, which converge on the supporting beam of the skate) is not subject to serious deformation;

- large sows from all sides protect the facade of the structure from precipitation;

- possibility of arranging an additional attic or attic room;

- an attic room due to such a roof design is heated evenly and well kept warm;

- the attic windows can be mounted directly in the roof slots - there is no need for the fronts;

- the external attractiveness that can be further emphasized by the well-selected roofing material.

The disadvantages are:

- the complexity of engineering calculations and erection;

- impressive construction weight;

- large financial costs are assumed than when the double roof is erected, but it should be noted that it is not necessary to spend money on the brickwork of the fronttones;

- water penetrates through the axle attic windows during the rain, while with windows placed in the two-tie roofs, such a problem does not occur.

Calculation of the fourth roof

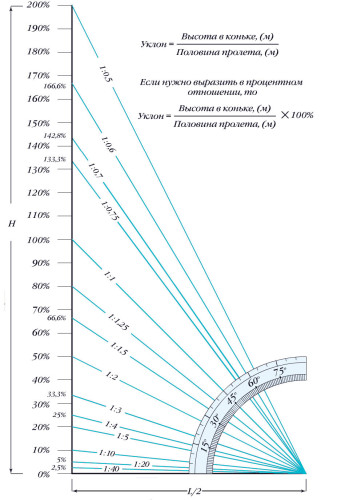

When it comes to the slope of the four-tie roof, there is due to the slope of longitudinal (trapezoidal) skates. To correctly define this parameter, it is necessary to take into account certain factors individually and in the complex:

- the slope depends on the design of the roof and the facade of the building;

- the greater the angle of the slope, the greater the consumption of building materials and the complexity of the work performed;

- the fastest roof slope can be in a wide range from 5 ° to 60 °;

- in regions with frequent and abundant sediments (especially worth considering winter snowfalls), preference is given to a large slope of the roof - from 45 ° to 60 °;

- in areas where strong winds prevail it is better to choose a small slope angle (from 9 ° to 20 °), which will significantly reduce the sail of roofing materials;

- if the roofing materials are typed from piece units, the roof slide slope should be at least 25 °, otherwise the moisture seeping will be observed through the seams;

- most often, the universal angle of inclination at 20-45 ° is selected.

Materials for the construction of a four-page roof

Before approaching the selection of the material, it should be noted that due to the specificity of the structure of the four-tie roof, when it is erected, a considerable part of the building materials will turn into waste. Therefore, the choice should be based on the financial capabilities of the customer. The most economical will be the material that consists of individual elements of a small size.

- for rafters, wept of coniferous breeds (pine, larch);

- it is necessary to pay attention to the quality of sawn timber (there should be no defects that can affect the strength and durability of the roof);

- in order to avoid deformation of the roof, the moisture of wood should not exceed 18-22% (it is possible to use the instrument to the instrument - the electrolyg meter);

- if the moisture content of sawn timber exceeds the permissible values, they need to be sued (produce drying in the shade, under a canopy and in drafts);

- for rafters, the optimal will be a rectangular bar (its section is determined when designing);

- an alternative to a rectangular bruster can be a board with a cross section of 50 x 100 or 50 x 200 mm (if necessary, dual boards are used);

- to increase the strength of the multicate roof, fastening elements of steel are used (they allow you to maintain a set of rafter unchanged);

- metal elements can be performed support for the most loaded skates;

- the highest strength is the combined structures.

Common types of hip covers:

- Flexible tile. It has a few more names: shingle, roofing tiles, Shinglas. This is not only the most economical coating option, but also the most low (1 m 2 Weigh about 8 kg). For the production of the foundation of such tiles, fiberglass impregnated with bitumen is most often used. It is the foundation that gives the coating flexibility and elasticity. Outside, the flexible tile is sprinkled with a shale, a basalt granulator or mineral crumb, which ensures not only protection against environmental impact, but also gives the roof a variety of shades.

- Metal tile. One of the most popular materials used for the roof. It is galvanized or aluminum steel sheets. Special layers in the composition of metal tiles prevent corrosion. Its weight is only 4-7 kg per 1 m 2and the color palette includes up to 45 shades. In addition, metal tile is an eco-friendly material. From the disadvantages of such a coating, it can be noted that it makes a strong noise when shocking raindrops or hail, and a lot of cropping is formed during the cutting.

- Ordinary tile. This is a natural material that represents tiles (flat or curly) from burnt clay. This is a durable, but rather heavy material (for 1 m 2 30-75 kg). Usually the clay tile laid on a powerful crate. To create the desired shade, can be covered with colored icing.

- Slate sheet. This type of material is used to cover the roof with a slope slope of more than 12 °. If the angle of the slope is less, it is possible to enter moisture through the joints of the slate sheets. The use of slate can significantly speed up the construction time due to the simplicity of installation. In addition, this is a very economical material. Of the minuses, there may be insufficient strength in mechanical exposure, as well as the ability to accumulate moisture that with sharp drops of temperature can lead to cracking.

- Ondulin. Bitumen, cellulosic fibers, mineral additives (as filler), fiberglass and resins (for strength) are used to produce this roofing material. Thanks to the mineral pigments, Ondulin saves its color for a long time. The cost of this material is low, it can withstand significant temperature differences, has shockproof and moisture resistance.

How to create a four-page roof project

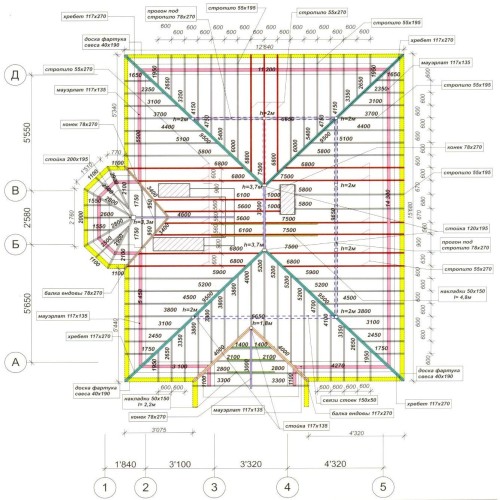

Designing the future roof is recommended to begin with the calculation of its solo system:

- select the type of design;

- analyze the probable load on the rafters (taking into account the winds in a particular region, the maximum mass of snow, the degree of the angle of the slope of the row);

- experienced builders recommend choosing rafters with a storage margin of 1.4;

- calculate step rafters;

- evaluate the carrying capacity of the rafter system;

- find out whether additional elements are needed during the construction of a rafter (for example, discolutions or tightening), because it is they who give the design necessary hardness and strength;

- decide on the coating material;

- taking into account the angle of the slope, calculate the height of the roof ridge.

How to calculate the load on the rafter system

There are two types of loads:

- constant (which consists of the mass of the roof, crates, rafters, insulation and runs);

- temporary (wind power, snowfall abundance, payload).

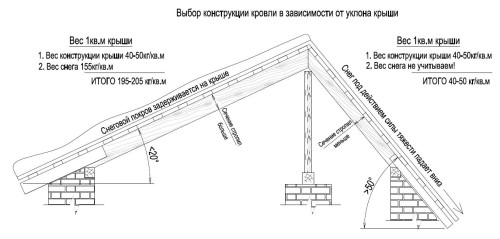

According to construction standards and rules (SNiP) in the middle lane of our country, the snow load is 180 kg / m 2. In the case of snow accumulation, this value may increase to 400-450 kg / m 2. With the corner of the roof slope of the roof of 60 ° and the more snow load in the calculation is not taken.

Wind load in the same region on Snip 35 kg / m 2, and if the angle of the slope is less than 30 °, then this value is not taken into account in the calculations of the roof.

There are additional correction coefficients for different regions of the country.

The payload is taken into account when the ceilings will be hung to farms or it is planned to establish water tanks, ventilation devices and other suspended objects.

When designing a rafter system of the future roof, special attention should be paid to the two main points:

- calculation of the strength of the rafters themselves (it is necessary to make sure that they will not break under the influence of loads);

- the calculation of the extent possible deformation of the rafter system with the selected parameters (for example, the deflection of the rafter used for the attic roofs should not exceed 1/250 their length).

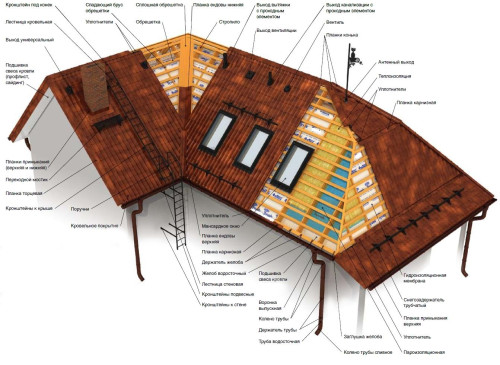

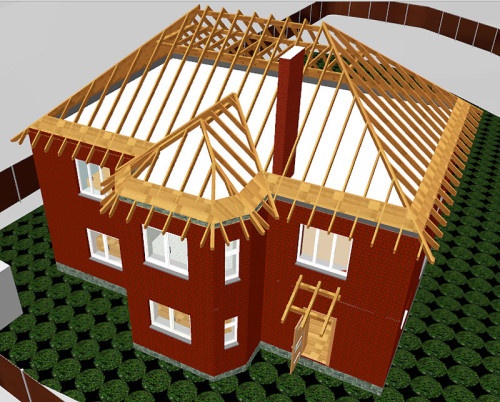

Installation of a four-page roof with your own hands

Before proceeding directly to the installation of a hip roof, it is necessary to process all the wooden parts of the future design with special fire fighting means. And to the places of contact of the tree with concrete or brick masonry to lay a rolled insulating material.

Mounting is performed in the following order:

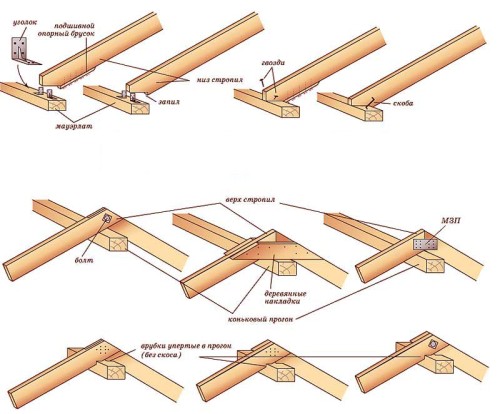

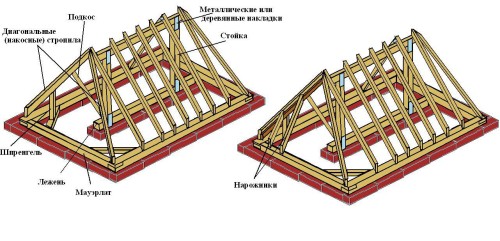

- laying around the perimeter of the Building of Mauerlat, which is a support for the entire future system (consists of a bar with a cross section of 100 x 150 mm or 150 x 150 mm);

- maurylalat is fastened with studs (with thread from M12 or more) or loops made of durable wire mounted in the wall;

- installation of the Lenzny (central beam of the rafter system) as a support for subposses and racks;

- the central beam is stacked on the inner wall of the structure or on special brick columns, which are located at the ceiling (in some cases on the slabs of the overlap);

- strictly vertical installation of special racks to maintain the skate (the strength of the entire future roof depends on it);

- fixing the skate timber with the help of a force system (be sure to use a plumb and rack);

- installation of diagonal rafters (exactly from them and from the skate run depends the height and angle of inclination of the roof). In some cases, they have to be collected from 2 parts, and then - for unloading the place of the joint - an additional support is installed under it;

- installation of ordinary rafters is made with a support for Mauerlat and the skiing timber (as well as diagonal, can be enhanced by racks or pins) with a pitch of 600 mm;

- strictly parallel to the ordinary rafters are installed angular (ninamers) so as to eliminate their convergence in one place. The length of these people will decrease as the approach to the corners of the skates;

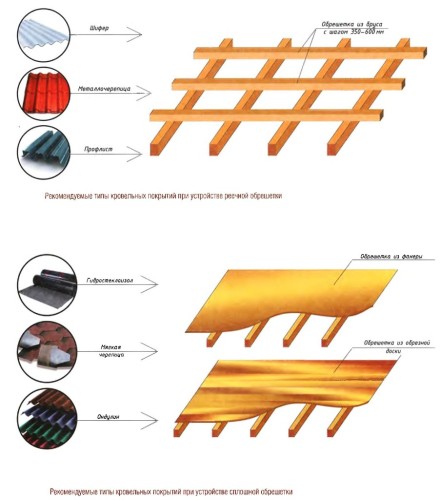

- installation of the crates passes in direct dependence on the selected roof coating (it can be solid or with gaps). Under the crate use bars with a cross section of 50 x 50 mm or boards, the thickness of which is 200-250 mm;

- laying of heat and sound insulation;

- installation of roofing material to the crate with self-tapping screws;

- installation of skate parts (long narrow sheet of material, which is bent in the longitudinal direction at an angle); The main roofing cover is paired along the upper edge of the roof, minor between triangular rods and trapezoids;

- eaves covering and installation of drainage (more practical use industrial stock system).

Based on the foregoing, it is safe to say that it is sufficiently difficult to make a four-tight roof, but this reliable design costs efforts and financial investments spent on it.

Start a discussion ...

Start a discussion ...