An important fact for obtaining animal products in large quantities, and most importantly, high quality is a microflora on the farm. It is especially important to maintain it in a barn, since the animals are almost constantly in the premises. To balance the temperature and humidity of the air, you need to properly install the ventilation system. Today the article will tell you how to do it with your own hands.

Methods of ventilation in a barn

To get good productivity on a livestock farm, you must adhere to two conditions. The first is the right, balanced feeding, the second is to ventilate the room, which allows you to get rid of excess moisture and resolve the temperature regime. Usually, the cowsmen are premises in which there are practically no windows. Moreover, even if the ventilation occurs through them, due to the change of air masses, it does not occur due to improper flow of streams. It is fraught with a decrease in immunity in animals and the emergence of various diseases, which significantly affects the life expectancy of the animal. Also ventilating affects the quality and amount of milk.

According to leading experts in the field of animal husbandry, reinforced concrete structures, from which almost all cowners are built are absolutely not suitable for the content of cows, as they significantly reduce their productivity. Concrete misses different temperature modes. So, in the summer in such cowshes there is an unbearable heat, the winter is cold. In this regard, the buildings need a full-fledged ventilation system for temperature control and air mass.

Natural ventilation in the barn with their own hands

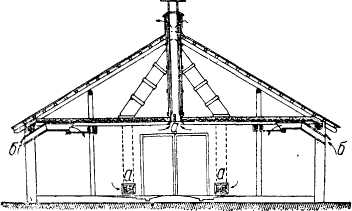

In the case of natural ventilation, the air exchange is done by itself: warm air goes through the mines in the roof of the building, and the cold enters it through special holes in the walls of the barn.

It is worth noting that the holes in the walls need to additionally equip the cassette filtering system, otherwise large dust fractions will be sent to the building. To equip natural ventilation, it needs to be developed before the construction of the barns. Handbook you will need to do a few simple events.

- We make a project of a barn, taking into account the ventilation system.

- The intake holes (those in which the fresh air will be included) are placed at the bottom of the construction, closer to the foundation. It is important that the holes are placed on the side of the wind roses.

- The inlet openings are inserted into the building by means of a regular pipeline. They are placed over the roof of the building from the opposite side. Due to this, there is a difference in temperatures outside and indoors, a zone of low pressure is created, and the stagnant air comes out.

- To regulate the air flow, the inlet openings supply dampers, and the output - exhaust ventilation deflector.

The advantages of natural ventilation:

- low cost of materials and installations;

- easy installation.

Cons of this ventilation system:

- dependence on weather factors. In this regard, such a type of ventilation is capable only to partially form a decent microclimate for animal life and in connection with these loses automated ventilation systems.

Forced ventilation in the barn with their own hands

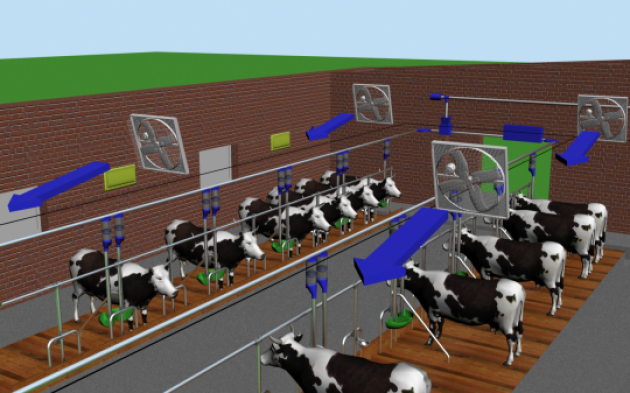

To date, the forced ventilation system is used in livestock centers most often. In this case, fans of tunnel, skate or circular type are used to circulate air, as well as intake and exhaust valves.

Forced ventilation is much more difficult to equip more than natural. Therefore, a more detailed work plan is needed.

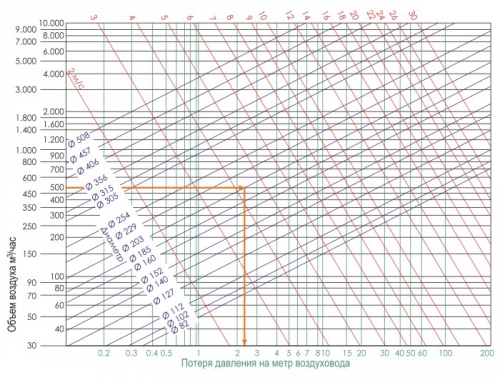

- It is necessary when developing a forced ventilation project, we calculate the pressure loss on each square meter of the air fuel. The calculation table is shown below.

- Next, calculate the performance of the fan. To do this, for the initial data we take two meters of cubic air from one square meter of the square in one hour. The resulting figure multiply on the volume of the barn.

- And the last thing we expect is the power of the fans. For this, the magnitude of pressure loss is multiplied by volume.

- According to the resulting data, choose a fan. It is extremely important to take into account all the parameters described above. So your barn will be fully ventilated, otherwise you will simply throw money into the wind.

- Mount the fan into the room according to its installation instructions. Structurally, it consists of two parts: exhaust (ensures the removal of "old" air) and inlets (prepares and "new" air).

Advantages of the system of forced ventilation:

- provides full ventilation due to the adjustment of air supplies;

- you can serve the air to the points you need;

- full process automation (air control sensors, controllers, calorifers, etc.);

- ability to achieve an optimal microclimate in the barn.

Cons of ventilation arrangement of this type:

- high cost of materials and installation;

- mounting complexity;

- requires constant costs further (on replacing filters, lubricant, etc.).

Requirements for ventilation system in a barn

The ventilation of the barn must occur systematically regardless of weather and season. As mentioned above, it depends on both the productivity and the health of the burenok. There are several livestock ventilation rules.

- In the winter period, the ventilation should be carried out at least fourfold air shift, along the perimeter of the entire room. In summer, this figure should exceed 60-100 times in a clock time.

- The speed of air masses in the winter should be about 0.2, 0.4 meters per second for calves and adults, respectively. Summer is allowed to increase wind speed per second to 0.6 and 1 meter.

- The most optimal humidity of air for cows is no more than 40% at a temperature of 25 (plus-minus 2) degrees Celsius. If the temperature exceeds the permissible rate, the animals experience heat stress.

- With the presence of a lattice floor, you need to install additional ventilation with a capacity of at least 35%.

Holding to all these rules, you guarantee yourself a generous "harvest" of milk, and your feeds will have excellent well-being and a healthy appearance.

Start a discussion ...

Start a discussion ...