Goat milk is an excellent raw material for professional cheesecakes. A hostess is made from milk with cheese, cheese rich in minerals and useful substances. In this regard, the desire to have a mobile milking machine is a clear phenomenon. Craftsmen can easily make their own home apparatus, saving substantial means, introducing their own know-how. Finally, the assembly process will bring exceptionally positive emotions.

Design

The most difficult thing in the process of creating a milking unit is to assemble from "zero", i.e. without having basic design or individual parts. In this case, you will have to finally pull out each workpiece on the lathe and collect the entire unit from the available parts. On the contrary, the concept of "from a difficult to simple" provides for the assembly of a milking machine with their own hands from previously trained finished nodes. As an example, you can collect an analogue of your favorite mass model using the technical data and the manufacturer schema.

Components

Whatever the model you have chosen as a preparation, it will include the following components:

- Engine. The entire machine will function from the power plant. An electric, mechanical or manual unit can be performed as an engine.

- Pump. Vacuum milking schemes are the most preferred option.

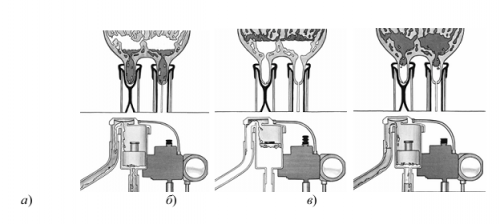

- Milking equipment. The kit includes: collector, bucket, pulsator, hanging knot, hoses for vacuum and milk.

Recommendations for the selection of components for the milking machine

When choosing a power plant, look carefully on power consumption and power. Most factory milking models are designed for oil pumps. For consumers, this option is unprofitable for consumers. First, oil pumps can leak. Secondly, the oil level is recommended on a regular basis. Finally, the pump work is accompanied by a strong noise. By the way, to level this effect can silencer.

An alternative to the oil pump is a water toll. Such pumps are not so noisy, more environmentally friendly, as a result, in demand. For a vacuum pump in the milking machine, an additional water tank is arranged.

Integrate the industrial pump is recommended for large loads. The engine for such an apparatus consumes about 4 kW. Such a choice will be justified if the milking apparatus for goats will be designed for at least 6 animals. Otherwise, energy consumption is hardly justified. By the way about energy saving. In the environment of experts, there is a sustainable opinion that the pump of domestic production is more economical than foreign analogues. It equally concerns the cost of spare parts.

Nuances

Pay attention to the suspension node. Save should not be saved, since the glass included in the element is in contact with the cutting of the goat. To control the level of milk, it is advisable to purchase transparent glasses. This will allow you to stop the milking machine for the goat. That is why dairy hoses must be transparent. When creating a two-chamber glass, specialists advise to take high quality rubber, which, when contacting milk, does not release toxic substances.

In order for the device to securely kept the excretion of the animal, it is advisable to use silicone suction cups. These elements with pressure reduction will allow not to fall around the entire node.

Board of experienced: Do not overdo it in order not to be released.

With respect to the collector and the pulser is not a single recommendation. If you manage to get a model Soviet-style pulsator, difficulties with maintenance will not. This part is still disassembled easily as going. Opting for an import model involves a relatively high cost of repairs. You might be interested pulsokollektor - a device that combines the pulsator and the collector. This variant is advantageous not only in financial terms, the work also has objective advantages.

First of all, this unit provides effective and natural operation. Goat milking experiences the same impression as when feeding. Even the animals tugodoykih milk milked completely. This reduces the risk of mastitis and fat content of milk increased by 0.1%. In fairness it should be noted that many of the complex pulsokollektor maintenance - developed under a sink bench. Yes, and the process requires disassembly-assembly of remarkable patience.

When selecting buckets have two options: aluminum and stainless steel. The first is easier, but are subject to corrosion; second - harder, but more durable.

Finally deciding to create a milking machine at home, stay close to the following points:

- specifications and documentation-analog circuit;

- search provider of necessary parts and sub-assemblies;

- technical difference between the models. When using models from different manufacturers may not perform the whole assembly;

- to animal testing, to thoroughly examine all the elements of the unit, run in test mode.

Milking Machine - unsophisticated device that meanwhile should work flawlessly. Qualitatively, the assembled machine milking mimics the natural feeding, at times increases milk yield and milk quality, reduce labor costs, save time. Vacuum machines are designed for applications where gentle treatment, in which the animal feels no discomfort. As a result, the quality and quantity should be increased. Therefore, the individual parts must not squeeze the udder goats, pulling it strongly. On the contrary, they are designed to massage the sphincter, thus transforming painful milking process in a short massage.

Start a discussion ...

Start a discussion ...