Manual work is useful without doubt and does not require investments other than practical experience. For years, women milked milk manually, not complaining of fate. However, this variant of producing milk is not attractive for several reasons. First, manual Nadya takes a long time. Secondly, it is not necessary to speak about the efficiency of work. Finally, it is inconvenient. Carefully changes the case of the milking machine, make it possible to make it possible, having enlisted with technical support and having small skills.

Planning

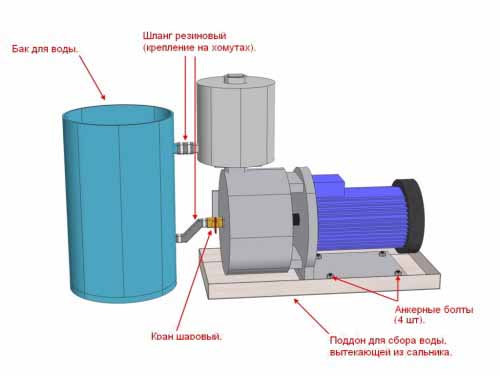

It should be highlighted that create a homemade milking machine completely from the undergraduate means will not be released. Even if you have excellent plumbing skills and have a lathe. The optimal option is to purchase ready-made nodes for the future unit, to acquire instructions and schemes for the operation of a technical node. And finally, to collect. All milking equipment available on the market consist of the following components:

1. Vacuum pump.

2. Madele complex. It includes:

- collector;

- pulsator;

- hoses for milk and vacuum;

- bucket for collecting milk;

- suspended node.

3. Power installation. She may be:

- mechanical;

- manual;

- electric.

Device of the milking machine

The standard industrial option consists of four milking glasses, a pulsator, a collector, a milking bucket, dairy and vacuum hoses. Milking glasses on the inside, as a rule, are trimmed, with an external - solid material. During the process of milking, these components are put on the nipples of the cow, forming a couple of cameras - under and around the nipple. Cameras through a pulsator and a collector are combined with a vacuum wire, a milk pipeline and a milking bucket.

The collector and the pulsator consistently create the effect of pouring and pressure in the chambers. If the chambers are combined with a vacuum wire, the system creates the effect of the vacuum. So sucks milk from the udder cow. When the camera near the nipple is connected to the atmosphere, and the other remains complete with a vacuum drive, sucking stops. This phenomenon was called compression. This is the action of the standard two-stroke apparatus.

As for the system of the three-dimensional milking apparatus for cows, it requires a complex technological approach when creating and impressive skills.

Tips of professionals

Pumps and engines

When choosing the main components for the future device of the milking device, pay close attention to the energy consumption and power supply indicators. In case the electrical engine has high power and power indices, this option will be appropriate for installation for 4-6 cows. For a mobile unit, calculated to two animals, there will be enough power up to 0.5 kW.

In the absolute majority of models produced there are pumps on an oil basis. This option is not attractive for several reasons:

- Technical oil can flow and disturb the sterility of the entire system.

- Oil level must be checked regularly.

- High noise, which comes from the pump. If necessary, level this gap is recommended by the silencer.

A much more justified decision will be the selection of a vacuum pump. Alternative analogue is more environmentally friendly, Beshume and unpretentious in technical terms. It does not require additional expenses and easy to handle. With a large number of cows serviced and installing an industrial pump, it is preferable to select the engine with a power of about 4 kW. Otherwise, energy costs will be in vain.

By the way, the pumps from Russian manufacturers are highly popular in the farmers environment due to low prices for components and ease of maintenance. What you can not say about foreign analogues.

Suspended node

Persistently focus on creating a suspension node. Savings are inappropriate here, since some components of the device, such as glasses, are directly contacted with gentle nipples of animals. Professionals advise:

- Choose transparent glasses that make it possible to visually monitor the Nadoy process.

- From the inside of the glasses, use exclusively high-quality neutral rubber, not distinguishing toxins. It equally concerns the milk pipelines.

- Use silicone suction cups for high-quality retention of glasses on udder. This will allow to keep the entire complex with a decrease in pressure to a gentle level in 30 kPa.

Pulsators and collectors

In relation to collectors and pulsators, there are no specialists for the milking apparatus of the unanimous opinion. Some recommend devices of domestic production, other foreign counterparts. On the one hand, the Soviet patterns of the pulsators are available and do not require significant efforts to maintain and repair. Imported pulsators require a one-time payment of significant funds, but this minus is compensated by the cost-effectiveness and efficiency, except for high prices for Repair Kit.

The optimal solution is the acquisition of a pulsicollector - two-in-one devices. This option will be attractive at cost, and on the working results. The pulsicollector meets world quality standards, approaching the work of the vacuum milking machine to natural feeding. After working, the cow does not need manual milking, even in cases with rigorous animals.

The percentage of milk fat increases, the risk of incidence of mastitis is reduced. Although such an aggregate is by no means on the teeth of ordinary farmers in technical terms. Assembly and disassembly takes a long time.

Additional elements

When choosing a bucket, preference is given aluminum and "stainless steel". Aluminum buckets are easier, but are subject to corrosion, stainless steel containers are harder, but more durable. Alternatively, you can use buckets from high-quality edible plastic. When choosing, do not ignore the tips of the experienced, which are not the first year use stationary or homemade installations.

Afterword

Finally decide to create a milking machine at home, do not miss the following tips from the view:

- With independent creation of the machine, thoroughly examine the experience of lovers and calculate the likely technical shortcomings. In the case of the creation of a poor-quality apparatus, it will be uncomfortable not only to you, but also an animal.

- Find available components for assembly. These can be both elements of domestic and foreign production. They apply to free access in specialized farm stores.

Keep in mind that even the models from one technological line differ from each other. Carefully learn the instructions for each node. - Be sure to have a scheme of the acting devices and their characteristics for comparison.

Start a discussion ...

Start a discussion ...