Alpine Beehive, also referred to as the hives of Delon or just Alpine, is considered one of the most successful inventions in the sphere of beekeeping. His design, though similar to those invented earlier hives, however, has some differences that provide the optimal level of comfort for bees and as a result is a rich honey harvest. In this article we will find out what these differences are concluded and tell you how to make the alpine hive with your own hands.

Features and characteristics of the hive

The Alpine Beehive invented a talented beekeeper, France's native, Roger Delon in the 70s of the last century. On the Soviet space, the design appeared thanks to the Ukrainian enthusiasts, after which it was instantly appreciated on dignity and spread throughout the territory of the former USSR. Even after so many years, many beekeepers prefer alpitz, carelessly believing that nothing better has appeared since then.

Why did the design work so successful? In fact, everything is very simple - the inventor of Roger cared not about getting more honey, and he tried to make life bees in captivity as comfortable as possible. That's the whole secret of success - the better there is a bee, the more honey they bring. As a result, Roger Delon came out a hive, ideally corresponding to natural insect habitats. According to the approval of the inventor, the Alpine Beehive is designed in such a way that the bees can even even winter. It also provides the previously accelerated development of bee families, and also increases their performance.

Unlike many analogues, this multiply hive is equipped with only one vehicle without a hint of ventilation holes or a separation grille. Externally, it is a little bit like a four-circuit, but still has significant differences. Roger Delon took the natural habitat of bees - hollow woody trunk for the original model. At the bottom of the flyer inside penetrates clean cool air, after which it is heated by the bee club and rushes up. In the process of movement of the bee, which, like all other living beings breathe, saturate the air with a mixture of evaporation, carbon dioxide and the exchange products, so that it is heavy and again falls to the flyer, through which it comes out. Thus, natural ventilation is provided in the hive. As a ceiling protruding the feeder, which prevents condensate. It lies on the hive constantly and performs the function of the airbag. The thickness of the insulator cover is as much as 3 cm, which is more than enough to protect bees from sharp temperature differences. When there are big bribes, the hive can reach more than 150 cm in height. To maintain a comfortable microclimate in it, the hulls are increased in full compliance with the size of the bee club.

To assess all the effectiveness of the invention, you can take a look at the information obtained in the "unsuccessful" years when honey was obtained least. Compared to other hives, Alpine distinguished positively. So, in the late 80s, only 2 kg of honey was collected in one Carpathian apiary with 50 Dadanovskaya hives, and 22 kg from Alpians. In the Alpine hives, they rebuilt 24 frames from the artificial trap, while there were none in Dadanov.

It is surprising that with the highest performance, alpine hives remain the most economical - for their construction, much less materials will need, and from the tinned wire, which in the afternoon you will not ourselves, you can refuse at all. The block method of the arrangement makes it possible to place a hundred bee-axes on the square in just 0.4 hectares, which is several times less compared to other structures. In this case, cases of bees and theft of honey are excluded!

As a result of a small amount of consumables for construction - the small weight of the finished design. Beehive with frames scored honey, will weigh only about 16 kg, 11 of which comes to honey. The hives correspond to the possibilities of bees to fill them with a nectar under the string and at the same time are very durable - they cannot be broken even in the honeycomb on the maximum rotor speed. The compact size of the Alpine Beehives allow you to fit a large number of structures in the car body.

With the onset of the cold season, alpine hives do not need to warm up pillows, rags or mats - it is enough to cover with a polyethylene bag. The inventor himself, who, how guessed, has its own apiary, it is easily controlled from 1000 hives alone. Fill honey with all one for very difficult, but you can do it in winter.

About all the advantages and features of the Alpine Beehive Operations are described in the video below:

We will summarize the brief results and we denote the main advantages and disadvantages of alpine hives:

- simple and convenient operation;

- efficiency;

- intensive development of beekeepers in the spring;

- there is no need to take serious events for wintering;

- high medical productivity compared to other structures of the hives;

- high number of frames with a carrier;

- easy to get a sectional cell honey;

- with proper assembly, the frame will not break in a honeyphone;

- convenient transportation;

- compact dimensions;

- easy to make with your own hands.

Oddly enough, this design has disadvantages, which, however, can be classified as features of operation, and not serious complaints. For example, because of the non-standard sizes of the framework, it is not so easy to choose a honey. Also, if you are going to move the bees from other hives to the Alpine, it will be difficult to do it - it is easier to set out such designs "from scratch". There may be difficulties with the purchase of beehosses on non-standard framework and bela packages. The latter is easily solved with the help of online stores, where you can find and order anything.

Making alpine ulya

Make an alpine hive is able to anyone who has suitable lumber, the simplest tools and correct drawings. With the latter, we are ready to help, and in this chapter step bypass will consider the construction technology of each part of the alpine. To begin with, consider the technical characteristics of the structure. We have already said that the thickness of the lid is 3 cm. The same applies to the walls and the bottom of the hive. The height of the slotted tray is 7 mm, the width is 30 cm. There is also an adjacent board installed at an angle of 45 °. The evidence has an internal section, equal to 30 cm. The case 108 mm in height places 8 frames. In its walls there are special ledges, which relieve metal combs for fixing the frames.

One glance at the Alpine Beee Frame is enough to notice the atponality of their design - they have no side and lower slats. The role of the planks performs the steel wire with a thickness of 3 mm, and in the top there is a hole where the artificial trap is inserted.

Beehives can be equipped with 3 or more enclosures (depending on the time of year, the type and performance of the beekeepers). Sometimes in the spring, only a few buildings are equipped, which are closer to the summer are filled, and you can hold the remaining. You can get to work in the winter time in order not to disturb the bees once again.

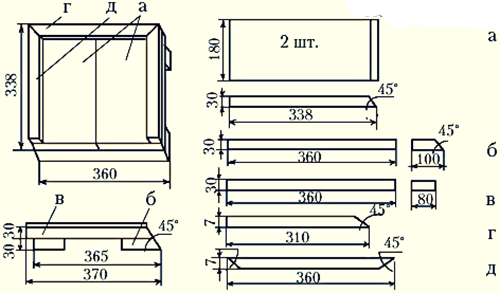

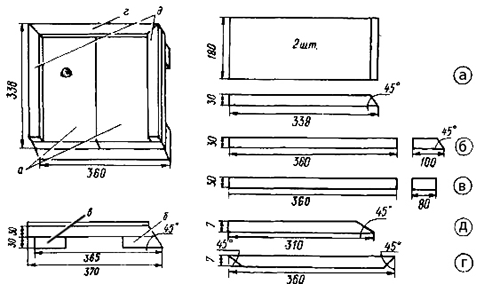

In the image below you can see the technical characteristics of the main details of the Alpine Beehive:

Consider the principles of the device of all components of the structure:

- The drawing below shows a housing consisting of three walls. The facade, rear and side panels are made of coniferous sawn timber 3 cm thick (spruce, pine, fir). First, build a frame of 4 walls, then increase the housing to the required height.

In the panels "A" there are protrusions for mounting comb-locks. This case involves installing 8 frames. Total buildings can be from 3 to 6, depending on the time of year and the number of future tenants.

The drawing also shows that the only flyer of the hive does not have separation lattices or ventilation holes. Overheating protection provides a lid.

- To assemble the bottom of the bee (a), it is recommended to choose coniferous wood with a thickness of 3 cm, soaked with flaxseed oil. The outer surface should be covered with carbnil and paint on an aluminum basis. The height of the pilot provide bars (g, e). The front and rear legs (b and in respectively) are also made of coniferous wood.

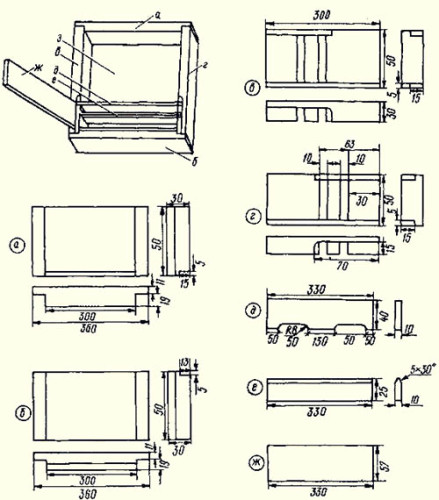

- The cassette consists of 4 panels and is necessary for collecting uterine milk and in the formation of the formation of sumps.

- The feeder is one of the most important details. It consists of rear (a), front (b) and side panels (B, D). There is also a partition (D) with a pair of passages for insects and a rack (E), which allows bees to eat sweet sugar syrup. The letter "F" is indicated by the lid and "s" - the bottom of the feeder. The most successful materials for the roof assembly are lumber from fir and fir. To collect propolis as quickly as possible, attach the rails on the back of the bottom.

- To make a frame with a trap, use a strap from a cherry or beech, as well as a steel wire with a thickness of 3 mm. The bar must be 2 openings on both sides through which the wire is made. In the widest part of the plank make 2 holes for laying a footbarr.

Perennial practice successfully proves that the framework of the Alpine Beehive is qualitatively different from all known designs. It is their non-standard dimensions that make it possible to completely fill them with nectar. At the same time, the framework remains very durable and not fall apart in medogon devices even at maximum speed, as it happens with other hives.

We hope this article if I did not convince the success of the idea to make such a house for bees with your own hands, I would at least intrigued. Drawings of the Alpine Beehive, outlined above, will help you build a working model.

Start a discussion ...

Start a discussion ...