The foundation is the basis of any facility. From its careful design and quality of work, the fate of the whole house is dependent: appearance, durability and reliability. Despite the fact that the supporting structure is mostly in the ground, the insulation of the foundation from the inside is the key to a comfortable stay in the house.

Why do you need a foundation insulation?

Quite often, the foundation is combined with basement walls. Operation of such a premises is possible only if its walls are insulated outside in places of contact with the soil. Few people know that the heat loss of the house from the foundation to the soil can reach 20% of the total heat leakage.

If the basement in your cottage is heated, correctly performed insulation will shift it from freezing, will not give the formation of mold, condensate and will not allow to develop fungus.

The insulation of the underground part of the house will minimize the impact on the foundation of the forces of frosty powder (the property of the soil is removed in the frost, since the moisture that freezes it in it, and as a result, expands). This issue is particularly relevant in the conditions of the middle strip, where the soil (clay and sublinous) refers to the category of prone to bent. When it is freezing, the deforming forces of frosty powered by the underground part of the foundation.

At first glance, insulation the walls of the unheated basement makes no sense, but it is not quite so. The fact is that in the conditions of a temperate climatic belt at the depth of two meters the temperature of the soil never falls below 5-10 degrees. Therefore, if you correctly perform the procedure for insulation of the walls of the basement, it is possible to maintain a constant temperature of about 10 degrees.

How to warm the basement?

Immediately note that the foundation is considered correct. What happens with walls when freezing and what troubles can be touched if the foundation is suspended?

- Inside the basement "drops" dew - condensate, and to separate such walls becomes problematic.

- Internally, insulation does not exclude the freezing of reinforced concrete foundation and achieve a comfortable living temperature in such a room almost impossible. In addition, the basement walls turn out to be unprotected from the effects of frosts, and this negatively affects the durability of the structure.

- The dew point does not disappear anywhere, which means that condensate still takes place. To combat it, a steamproof membrane is used.

- Thick layers of insulation steal useful internal space.

- In such a room, a characteristic microclimate with high humidity is formed. From here - the cost of ventilation and heating.

- In comparison with the outer insulation, the inner is somewhat more expensive.

The insulation of the foundation of the house from the inside - the measure is rather forced when the building standards of thermal insulation were not observed or turned out to be ineffective.

There are several ways to insulate the foundation and all of them are part of the finish finish. There is one general rule - before the start of thermal insulation, the foundation should be waterproof.

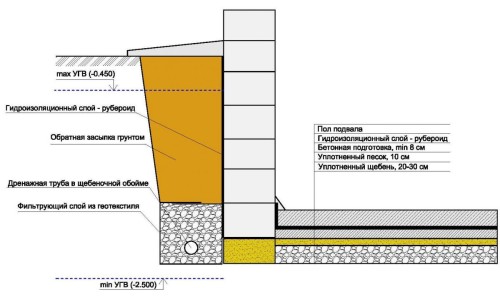

Waterproofing foundation

The highest quality is the technology of penetrating waterproofing. Concrete, being a porous material, absorbs water into its capillaries and passes its molecules rather deep. When they freeze it inside, the micro-channels are destroyed, and cracks and leaks are formed in concrete. From contact with water and air, metal reinforcement is subject to corrosion, resulting in further destruction of the foundation. With direct contact with the soil, the concrete can be further loaded: except for water, it is an effect of alkalis, acid deposits. Popular methods of waterproofing are coating and ever, ensure easy protection, but with insignificant damage, water is passed, losing their qualities. To do this, during the arrangement of such isolation, the drainage system for moisture is always provided.

In the case of penetrating waterproofing, pores and capillaries of concrete are filled with a mixture, where it reacts with aluminum and calcium ions, creating a small-molecular crystalline. Through such a lattice, water can only penetrate in the form of a pair. An interesting feature: the growth of crystals inside the moisture concrete not only does not interfere, but it is necessary: \u200b\u200bwith its help they grow to a depth of up to 60 cm. This is the ideal option for working with a wet foundation, it is possible to apply it both inside and outside the building.

Waterproofing is in the form of an aqueous solution (mainly for new buildings), a mixture for operation with a spatula (for the restoration of old structures), a thick mixture for protection of seams and in the form of a composition to eliminate leaks.

The processing of a new or monolithic foundation is usually produced by a liquid solution:

- The surface is cleared of dust, fatty and other spots. To open concrete, it is recommended to clean it with a metal brush, and then rich in water.

- According to the instructions, a waterproofing solution is mixed until the consistency of the liquid is sour cream.

- The composition is applied, preferably on both sides of the structure, two layers with a wide brush with an interval of 3-6 hours. If the interval is exceeded, the first layer is cleaned with a brush.

- Complete concrete drying for subsequent decoration occurs after 21 days.

Insulation of the foundation from the inside with their own hands

Among the methods of thermal insulation, the following three are most often applied:

- Warming with a falling method, which allows to reduce heat loss through the overlap of the first floor. Used purely for small country houses with short-term stay. Pulling the basement of the ceramic pebbles of volcanic origin is a cheap method that creates a warm air layer in which water does not accumulate. You can fall asleep all the free space or mount the formwork with the gap around to protect the mixture from contact with condensate.

- The use of foam or polystyrene with further interior trim. The popular method for buildings, where basements - residential or economic and most often combined with the street thermal insulation of the foundation. Since these materials are moistureproof, then, in addition to penetrating waterproofing, ventilation is equipped operating both on the input and the output.

- Internal insulation of polyurethane foam effectively both for additional and for the main heat insulation. The coating creates a seamless texture and is perfectly held, but the application procedure itself is more complicated and more expensive.

- Warming with thermal insulating material with reflector and masonry from foam blocks. This effective way makes room suitable for accommodation and organization in it, for example, the simulator room.

How is a falling thermal insulation

- From the board or furniture shield around the perimeter of the foundation, formwork is made to the entire growth of the basement and at a distance of 35 cm from the walls.

- The wood frame is necessarily soaked with antiseptic composition for a tree in contact with the soil. Sucks are made as fortifications.

- A polyethylene film is placed on the bottom, which will not give the ceramisit to absorb soil waters.

- Claims is falling asleep to the top level of the wooden frame.

- For effective overlap isolation, a layer of mineral wool and a vapor-permeable film is laid between the varnish floor lags.

Occasionally, when the height of the foundation is small, it is allowed to fall asleep clay directly into its cavity, only with a preliminary flooring of the waterproofing film.

Hearth polystyrene

Penoplasty foam plates are widely used for insulation of voids in carrying structures, as they have good strength characteristics, light weight and low cost. Polyfoam does not absorb moisture, it is easy to process, but a significant disadvantage of material is combustible when exposed to a flame source. Being self-fighting, polystyrene does not support combustion, but during severe heating it becomes extremely toxic.

Various manufacturers are on the market of plates of different density, thickness and stability. Depending on the use of the room, the material is purchased with a thickness of 50 to 100mm thick for the insulation of the foundation. For the subsequent finishing finish, it is recommended to choose the plates with a rough surface - it will be better to hold the plated mixes.

The insulation of the foundation of the foam from the inside is made in this way:

- First, walls are prepared: they are aligned and adjusted by level. If chipsets occur and potholes, then the nearest section of the wall around them is dismantled and is carefully filled with a waterproofing mixture for the repair of cracks.

- Overall waterproofing is performed, and if there is no external insulation of the foundation and the soil of the region are susceptible to swelling, then such insulation must certainly be deep penetration.

- The polystyrene foam is fixed in a checker or by combining the tongs on special glue, on an acrylic, polyurethane or cement basis. The glue is prepared by mixing or purchased ready, it is applied point, 6-8 smears, after which the sheet is pressed against the surface.

- Then the foam is fixed with a plate of a plate-type with a calculation of 4-6 dowels per sheet. The dowel must enter the wall by 30-50 mm, so the corresponding holes are drilled into which the dowel is inserted, and the special nail is rushed with the plane. The head of the dowel should not be less than 60 mm in diameter.

- At the joints, the foam is launched with a sealant.

- Unfortunately, polystyrene is afraid of rodents, so at the end of its installation, it is recommended to establish a reinforcing mesh from a metal or from fiberglass. The plaster grid is suitable with 5 mm cells. An adhesive solution is used for operation, for example, Ceresit CT85, thoroughly stirred in the correct proportion.

- The composition is applied over the entire wall, acting from the angle and on top down, then the grid is empty into it in the angles of about 10 cm.

- Subsequent pieces of mesh are superimposed with a total of 5 cm, after which the walls are sharpened once again adhesive to the formation of a homogeneous surface.

- Now the wall can be placed under the finish finish.

- All operations are done equally with walls and ceiling.

Remember: Materials in contact with expanded polystyrene should not contain any organic solvents, such as gasoline, acetone, kerosene, White spirit. This applies to glue, waterproofing and finishing mixtures.

Insulation polyurethane foam

PPU - today the most advanced insulation. Only it is an absolute thermal conductivity leader, because 97% of the frozen substance make up bubbles filled with insulating gases and air, which practically do not conduct heat.

Polyurethane foam is perfectly applied to any surface by spraying and does not require its pre-processing. It has good adhesion to the basement concrete, since some time after applying remains in liquid form and penetrates each corner of the surface, in each of its microfore and gap.

Turning into a polymer foam, the material becomes monolithic with a wall where there is no place for the bridges of cold and gaps.

PPU has a minimum water absorption, as a result of which it carries and a waterproof function. Its advantages can be attributed to the speed with which work on insulation is produced, as well as a guarantee of the quality of material for 30 years of operation. In addition, polyurethane foam is safe for humans.

Heat insulator with reflective layer

A set of thermal insulator with a reflective layer (aphlex in, escape, the thermophole) + a block of foam concrete 10mm thick, is very effective, as it has a low heat loss and does not allow the formation of condensate.

- The material of the heat-insulator practically does not miss moisture and steam, while its layer with foil reflects infrared rays. It is easy to lift and attached with liquid nails on any surface. Placed reflector inside the room.

- Further, the walls are placed foam block, with a gap of 15-20 mm between the masonry and the heat insulator. Foam blocks are easily processed by conventional hacksaw and also play the role of heat insulators.

- In turn, the floor is insulated with a reflective layer, falling asleep by clay and closes with floor plates from the KNAUF gypsum, which are stacked on the principle of the collection floor with a bulk basis.

- At this stage you can immediately move to finishing work.

The disadvantage of this method is that consumables are not seeking and use it better in spacious premises, because some part of the useful space "rustles" by masonry.

As practice has shown, consolidate the insulation indoors is an easy task. To bring the surface to the perfect finish coating after this - that's where construction skills are needed. Additional to learn about the insulation of the foundation from the inside will help video material.

Start a discussion ...

Start a discussion ...