It is known that the durability of the house and the quality of living in it depends on the proper structure of the foundation. In the room it was dry, warm and cozy, the base of the construction should be isolated from moisture and cold. In this article we will talk about the insulation of the foundation by polystyrene foam.

What you need to know about the insulation of the foundation

The implementation of such a work will allow you to achieve the following results:

- ensuring a comfortable stay indoors;

- reduce building heating costs;

- protection of the soil around the base of the house from the swelling and freezing and, as a result, the prevention of the foundation and the most buildings from the destruction;

- creation in the basement of the house of comfortable conditions, thanks to which the room can be landscapped and used for various purposes.

It should be known that the material for the insulation of the foundation must have certain properties. Among the basic requirements can be selected as follows:

- Low thermal conductivity, which will be stored in room temperature acceptable for living.

- Water resistant. If the material absorbs a lot of water, its thermal insulation properties of this deteriorating. In addition, moisture in winter becomes ice, which leads to deterioration of insulation, deformation and fracture.

- High strength. Since the material is used to insulate the part of the house, which is under the ground, it will be constantly subjected to pressure of the soil.

Main characteristics polystyrene

Let's look at the positive and negative sides of the insulation material. The advantages of polystyrene include the following features:

- It has a light weight, which makes it easier to transport it. Weightless sheets is easy to carry and load in the car, in addition, they can not damage the interior of the car upholstery during the trip.

- Ease your work with the material makes it possible to insulate the foundation polystyrene with their hands, without involving the experts. Such coating without problems cut into pieces and is mounted on the surface by means of adhesive or dowels.

- Foam is not afraid of insects.

- It is practically waterproof.

- It has a good capacity to retain heat.

- Styrofoam is a good shumoizolyatorom.

- He is not subject to rot, corrosion, it does not grow mold.

- This material is considered environmentally friendly.

- It has a high compressive strength. This indicator in the foam is at least 20 t / m².

By cons coverage include:

- Fire risk and the ability to break down when exposed to UV radiation.

- Exposure to mechanical damage.

- In case the tape base unit, the part which protrudes above the ground, it is necessary to carry out an additional outer finishing plastering, tiling or other materials.

- Expanded polystyrene can not be mounted on the hot bitumen mastic, and to use glue containing organic solvents.

types of styrofoam

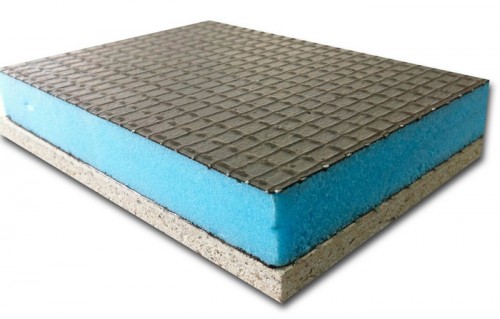

In today's market of construction materials are two main types of insulation: expanded and extruded polystyrene. Let's examine them in detail.

extruded polystyrene

This material is also referred to XPS letters. It should be noted that this kind of coverage has a somewhat better quality, and therefore, many prefer to use the extruded polystyrene for insulation of the foundation. Its main advantages include:

- good ability to maintain heat;

- a high level of compressive strength, this indicator for this material varies in the range of 0.25-0.5MP during the deformation of the surface in 10%;

- the extruded polystyrene foam has a homogeneous porous structure, and its pores are closed, which provides a good water repellent material function;

- due to the fact that such a coating does not absorb moisture, it is not subject to freezing;

- another plus of this insulation consists in its durability, if you believe in some manufacturers, the service life of the material is about 50 years.

Foamed polystyrene foam

It is also called foam and denoted by letters EPS. Such material is also used as insulation for the foundation. Like the previous type of coating, the foam has a low level of thermal conductivity. Among its main advantages can be distinguished by a small cost, however, in terms of its qualities, EPS expanded foam is significantly inferior to XPS polystyrene foam. The difference between these species is as follows:

- The foam is capable of absorbing a significant amount of water, which reduces its thermal insulation properties. Because of this, after the cladding of the foundation, it is necessary to create an additional waterproofing layer.

- Compressive strength in foamed polystyrene foam is 3 times lower than that of its extruded analog. In this regard, there is a need to protect the coating from the pressure of the soil.

Given the above characteristics, the technology of insulation of the foundation of the foam polystyrene foam polystyrene should include the following types of work:

- creating on top of the insulation of the waterproofing layer from bitumen, roll roofing or any other suitable material;

- construction around the foundation of the brick wall or coating of the structure with profiled membranes from polyethylene.

The process of insulation of foundation

Choosing plate thickness

To date, the plates of the material of various thicknesses are presented on sale, this indicator ranges from 3 to 12 cm. To decide which option you will be more suitable, some factors should be taken into account, among them:

- the purpose of the basement, if any;

- the material from which the foundation and the ground floor was made;

- the thickness of the basement walls;

- the prevailing climate of the area in which the structure is located.

For example, if the house is built in the middle lane and has a basement, it is best to use for insulation extruded polystyrene foam of about 5 cm. In the case when it is planned to create a sauna or a residential zone in the basement, it is better to give preference to 10 cm thick plates. Also add that the corners are most implanted in the building, so in these places the foundation should be insulated with a thicker layer of material.

Work process

The insulation of the foundation of polystyolistol outside consists of the following steps:

- First of all, you need to turn the foundation around the perimeter of the house. The depth of the trench should be taken to the lower point of the base, and the width of the pit should be such that it was convenient to work in it.

- With the surface liberated from the soil, it should be removed with a nanile soil, fragments of building materials and other trash. It is desirable that the wall was as smooth. If there are too noticeable protrusions on it or depressions, they need to be eliminated.

- The next step you will need to make the foundation waterproofing. It can be performed from coating, rolled or sprayed means - the option depends on your desire and budget.

- Determine the depth of the primer of the soil. If the bottom point of the foundation is below this indicator, then the distance from the base sole up to the soil freezing line will need to fill in sand. It is not necessary to warm the wall in this place, but the waterproofing will have to perform.

- After the foundation is protected from moisture, you can start the installation of polystyrene foam plates. Fasten elements best with adhesive mixtures. As mentioned earlier, the use of compositions based on organic solvents and hot mastic is categorically contraindicated, as they damage the material and reduce its thermal insulation properties.

- Apply adhesive on a sheet of expanded polystyrene. One fragment of 1x0.5 m in size will be needed in 6-7 places.

- After applying the composition, the insulation must be pressed to the surface of the wall and hold in this position 30-60 seconds.

- Begin the insulation of the base is best from any lower angle, moving along the design. If you plan to cover the foundation with several layers of the material, then the second layer must overlap the previous one in the checker order. So you will close the joints of the first level of the plates and improve the heat insulation.

- The corners of the building should be isolated more carefully, because it is through them that the most cold is getting into the room. The polystyrene layer in these problem areas should be somewhat thicker, so it is recommended to stick an additional fragment of the insulation on each side of the angle.

- The outer side of the polystyrene foam, as a rule, does not require additional processing, unless the foundation protrudes over the ground level. After the process of insulation of the base will be over, the trench around the building should be filled with sand and earth. Pick up the soil is better than layers, gradually her tampering.

- If, in addition to the foundation, you will also insulate the ground floor, then the material is better fixed with special plastic umbrella dowels - they will keep the plates more reliably than glue.

Warming foundation polystyrene foam, video:

Start a discussion ...

Start a discussion ...