The trim of the facade of the building and plaster walls is an important step in the construction and repair process. The facade is an indicative part of the house, forms the impression of his style and creates a certain image. Also, the outer part of the structure is regularly subjected to the negative impact of such atmospheric phenomena, as high and low temperatures, rains, rays of ultraviolet. Avoid the destructive effect of these factors can coating the facade with finishing material. Today there is a wide selection of compounds for outdoor cladding. Among the diversity of materials, plaster for facades is occupied.

Characteristics of facade plaster

The purpose of the facade composition for lining of the walls is to perform two functions:

- The priority task of such a coating is to protect the building from negative atmospheric influences, as well as mechanical damage.

- The second assignment of the finish is to create the desired decorative effect.

By adding the dye to the binder composition, plastering is performed, with the result that today you can find about 1000 colors of this finishing material. However, this indicator is inferior in a variety of color range by building paints, since the tinting of the plaster composition does not imply the achievement of deep colors. This is explained by the fact that to obtain a more rich color, a longer mixing of the composition is required. In the case of facade plaster, such a condition may adversely affect the quality of the material.

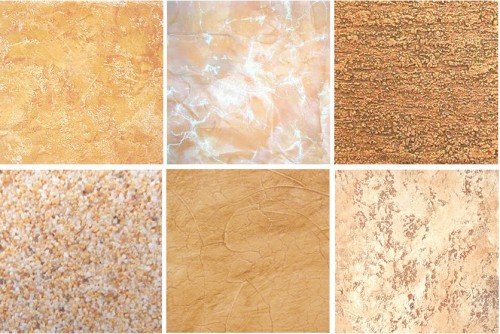

Stucco photo:

Benefits of material

The following advantages characteristic of all types of facade plaster can be distinguished:

- The quality of the composition, its elasticity and high adhesion ability to any reasons.

- You can store the plaster for quite a long time and at the same time the material will not lose its properties.

- This composition is distinguished by resistance to various mechanical and atmospheric influences. The finishing layer will not be damaged as a result of the influence of moisture, low temperature or mechanical loads.

- The plaster material does not secrete toxic substances.

- Finishing does not require careful care. The coating is easily cleaned by washing, and some types of material have self-cleaning properties.

- Unlike other facade coatings, plaster does not absorb pollution.

- The material has the property of steam-resistant, thereby ensuring a comfortable microclimate indoor.

- This mixture is already on the market already in prepared for use. The cooking technology is pretty simple and will not require high time.

- You can buy plaster in a wide variety of textures and shades, which makes it easier to choose the optimal composition for the overall design concept.

Type of plaster: Advantages and Disadvantages

Plaster for facades varies depending on the size, shape and type of grain filler, as well as from the type of binder item. Consider in more detail the positive and negative sides of each type.

Acrylic-based coating It has good parrotability. That is, such a mixture has the ability to give excess moisture in the case of its penetration into the pores of the material. This property is ensured by the composition of the aqueous dispersion of synthetic resins, which performs the function of the binder of the finishing composition. Also acrylic facade plaster is elastic and resistant to changes in temperature indicators. This coating is not scary of the impact of microorganisms, since the material is protected by special biocidal additives.

As a lack of this finishing composition, it is possible to distinguish that due to the lack of electrostaticity of the plaster can be contaminated. But due to the low absorption, the dirt will not penetrate into the coating structure, and it will not be difficult to delete.

Silicate facade material It has a high property of paroqueness. This makes it possible to use this coating where it is impossible to apply standard acrylic plaster. The silicate finishing material is characterized by neutral electrostaticity thanks to which the facing will not absorb contamination. The binding element in this coating is the potassium liquid glass.

Mineral Plaster Contains cement in its composition, which serves as a binding element. Thanks to this factor, the finishing material has the highest strength indicators among all varieties of facade facing. At the same time, the cost of such a coating is low. The finished product has the form of a dry mixture, which includes cement and various additives that reduce moisture absorption. Mineral-based plaster is not afraid of the effects of mold and fungi.

The only disadvantage of such a finishing coating is a limited choice of color gamut. But from this position there is a way out. If there is no required color, you need to finish with white plaster, and then paint it with silicate paint for the facade. It follows to use the paint of this type for the reason that it will not affect the steam-resistance of plastering cladding. Additionally strengthen the finish and do painting already after two days after applying the plastering layer.

Silicone type plaster has a number of advantages. Among the main factors, an unlimited choice of color range can be allocated, high indicators of elasticity and paropropusity. The decoration of silicone plaster does not require substantial care, since contamination from it is washed off with rainwater. As a lack of material, you can allocate high cost of products.

Application of material

Gypsum plaster for finishing facades has a fairly good adhesion in relation to all surfaces. It can be applied to such bases as concrete, aerated concrete, foam concrete, stone or brickwork, wood-cement plates. In order to obtain the highest quality facade finish before applying, it is necessary to prepare the base accordingly:

- the surface on which is expected to apply the composition, it is necessary to thoroughly clean from pollution;

- then degrease and give dry;

- at the end, a layer of primer should be applied.

Method for preparing and applying

- For the preparation of the solution, 25 kg of plaster can be placed in a separate container and pour 6.5 liters of clean water.

- With the help of the electronically apparatus, the composition must be kneaded to a homogeneous mass. It should be traced that there are no lumps in the mass.

- Then you need to take a break for 3 minutes and mix it thoroughly.

- The procedure should be performed at 20 ° C. The resulting plaster composition is suitable for use for 4 hours.

Apply the wall with two ways to the surface of the wall:

- mechanical;

- manual.

Mechanical application method It implies the distribution of plastering with a spray gun. For some indicators it is more convenient than manual. As a result of its application, the finishing process is significantly accelerating and costs less cheaper. But at the same time, this technology has its drawbacks - this is an inaccurate consistency of the composition and uneven distribution over the wall.

Method of manual application implies twisting with the help of a trowel. At the same time, the technology has some features:

- To form a certain surface texture, the layer of plaster should be sweetered using a plastic halfter.

- Perform this procedure after a few hours after the finishes are applied. At this point, the composition will become tough, but not yet grabbing.

- It is important not to miss the moment, because if it is too early to rub the plastering material, the finishing layer will disappear from the wall.

- In the case of late grouting, the composition will have time to grab, as a result of which it will be corrected almost impossible. The thickness of the plastering layer will correspond to the size of the grain of the filler.

- It should be borne in mind that in the process of drying the plaster, it should not be subjected to direct ultraviolet rays or temperature effects.

Recommendations for the process

In the process of finishing the facade with decorative plaster, some points should be taken into account:

- It is not recommended to fit the wall surface, which was recently folded. In case of laying, cracks may appear on the finishing material.

- On the surface of the concrete wall, the finish should be performed using a lime composition, avoiding the use of gypsum coating. When connecting plaster and cement, a chemical reaction occurs, as a result of which the layer of plaster will sweep and disappear. In addition to this gypsum, penetrating the wall may cause its destruction.

- It is extremely recommended to carry out finishing works at a temperature indicator below 5 ° C, as well as rainy weather.

- Starting the workflow, it should not be interrupted. This may affect the quality of the final result of the work.

- If nevertheless there was a need to suspend work, you need to use the plastering and painting ribbon. This will create a view of a continuous coating.

Manufacturers of plaster

The construction market today offers products of domestic and foreign companies. Among the most popular manufacturers include such firms:

- austrian company Baumit;

- finnish company MAXIT;

- german companies TEX-COLOR;

- czech company Stomix.

Among domestic producers, such trademarks can be noted as "Polymin", "Polish", "Tokan", whose plaster at a price is significantly less, while quality characteristics remain at the proper level.

Conclusion

As a result of the coating of the facade with a plastering composition, the building will acquire aesthetically attractive appearance, and in addition it will be protected from the destructive influence of environmental factors. Plastering mixtures that today offers the building materials market, easy to use and have a number of advantages that indicate the reliability of the compositions.

Plastering technology is presented on a video capture:

Start a discussion ...

Start a discussion ...