Plastic panels made of polyvinyl chloride as it is impossible to suit the decorative decoration of the inner walls and ceilings of the premises. They are easy to install, have a small weight, beautiful surface, moisture resistance and many other positive properties. On how to install PVC wall panels, we will tell in this article.

Characteristics of plastic wall panels

Considering the characteristics of PVC panels, I would like to pay attention to the positive properties of such a material:

- An important advantage of plastic finishes is its durability. Some manufacturers ensure that their goods will serve at least 50 years with due operations.

- Polyvinyl chloride panels protect the surface of the walls from negative external influences. For example, plastering or colorful coating, as well as wallpapers you have to update once a few years. There is no need for panels from plastic in it, it will be enough to periodically wipe them with a damp sponge or a rag, so that the wall retained an attractive view for long years.

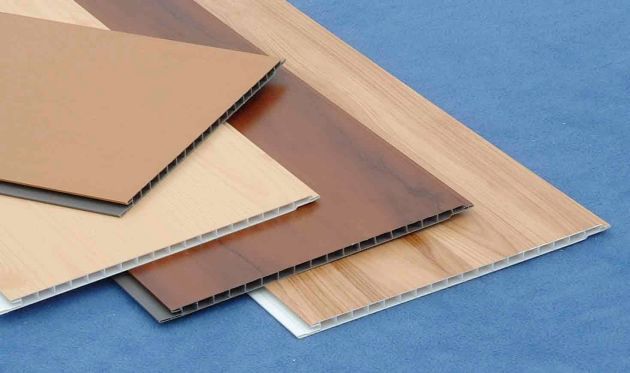

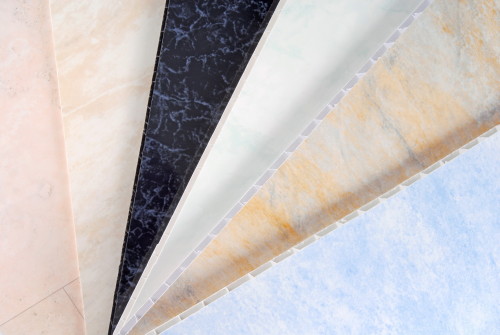

- Polyvinyl chloride panels are presented in the market in different colors and formats, the material can be used to finish large planes or relatively small architectural elements. The leaf wall panels of PVC can be facing extensive areas of industrial premises, as well as draw up walls of residential buildings and cottages.

- The speed and ease of installation can also be attributed to the benefits of plastic panels. Lining the wall with your own hands is easy, the material has low weight, so work can be carried out alone.

- The material from which the walls are built does not matter, since the plastic finish can be mounted almost on any surface. By the way, the working foundation does not need careful alignment. Of course, noticeable wall defects need to be corrected, but with small lablems of PVC panels with ease.

- If you have such a finish on the walls, you can easily hide wiring. If plastic parts are attached to the crate or frame, the free space is formed behind them, where the wires can be paved.

- Panels have good sound and heat insulating properties.

- Plastic moves well to low temperatures, so the finish can be used to be used in unheated premises.

- PVC panels can melt from fire, but the burning process they do not support.

- Another indisputable advantage of the PVC wall panels is their acceptable price.

- Plastic finish refers to environmentally friendly materials and is not dangerous to health. Such panels are simple in care and easily cleaned by wiping with a wet rag.

- The moisture resistance of the facing allows it to apply it in rooms with a wet environment, for example, in bathrooms, toilets, shower, kitchens, on loggias and balconies.

- In the process of installing PVC panels, there is almost no waste, construction garbage and dust.

In the construction market, PVC wall panels are presented in various sizes. Standard width is 100, 250 or 375 mm, and length - 270, 300 and 600 cm.

Negative properties of the material is not so much. The most significant drawback is that according to the rules of fire safety, it is forbidden to use plastic for the decoration of walls in the corridors and on the staircase spans of public buildings.

Scope of the PVC wall panels

Panels made of polyvinyl chloride can be facing various surfaces: internal walls and interior partitions, walls of balconies and loggias, bathrooms, toilets, kitchens, shower. Water repellent and frost resistance allow us to apply material for facing facades, unheardous rooms and rooms with high humidity. Environmentally friendly material makes it possible to use it in residential buildings, including in children's rooms. Such panels can often be found in public buildings, for example, in cafes, bars, offices, banks, etc. Sometimes PVC panels are used to create neat and smooth window slopes.

Installing PVC wall panels

There are three most common ways to install plastic panels. Below we will consider in detail each of the methods.

Installation of facing material with glue

If the walls in the room are made of concrete and have a fairly smooth surface, the PVC panels can be installed by gluing them. This process consists of such steps:

- First of all, the working base is carefully laundered from pollution and dust. The purpose of washing is high-quality degreasing of the surface, which is simply necessary for good adhesion of glue with concrete and plastic.

- Purified surface is left for a while that it is completely dried. Then they start using PVC panels.

- To install facing material, they often use such common means as titanium and liquid nails glue. The first thing on the wall is assembled by the starting profile.

- Then, part of the working surface is covered with adhesive solution. Applying the panel to the base, it is raised in the starting profile, tightly pressed to the concrete and hold so for a few seconds until the glue grabs.

- After that, the glue is revealed by the next section of the wall and apply a new panel to it, the crying of it under the protrusion of the previously installed part. PVC panels for ease of installation are equipped with special details: protrusion and shelf. But there are other elements on both sides of which the grooves are located. These parts are used for facing internal and external wall corners.

- If during the installation process some panel has to trim, for this we use a durable sharp knife.

- This method is separated by the entire surface of the wall. The final stage of the process is to install a ceiling border and plinth.

How to mount PVC wall panels on the crate

Walls built of brick or wood can also be separated by plastic panels, but in this case it is better to mount the cladding to the crate. In a dry room, as well as where the walls are made of wood, it is also better to use a tree for the crate. Consider a phased sequence of work:

- The bars and rails, of which the lamp will be created, it is desirable to pre-process protective equipment for wood and let them dry. Installing wooden elements need parallel to the floor surface. A distance of 30-40 cm should be observed between individual slats. As for the thickness and width of the wooden elements, these indicators may be arbitrary. If there is an electrical wiring or a layer of heat insulation between the wall and panels, then it is better to choose racks thoroughly.

- The wood wall shaft is mounted using self-samples, be sure to check the smooth construction of the construction level. Rakes in the right places can be easily trimmed with a knife or a branch.

- The smoothly installed clamp fixes PVC panels, fixing them with nails, small self-draws or metal brackets. Staples are driven into the frame of the stapler. The last type of fasteners is currently considered the most popular, since the work can be done quite quickly.

- The installation of panels start with the angle of the room, moving towards the window or door to the door. In the installation process, the result periodically check the level.

Installation of PVC wall panels on metal

To the walls built from brick, slag blocks or other modern materials, plastic panels can be attached using a metal profile frame. The advantage of this method is that there is no need to level the working base before finishing. The frame will help hide a variety of wall defects and eventually the surface will still look even and neat.

The crate is created from a standard galvanized profile, which is often used for mounting plasterboard structures. For such work, you need to stock such tools:

- construction level and plumbing;

- stepladder;

- line and tape measure;

- as a carbon;

- perforator, boots;

- a knife and a grinder;

- marker or pencil;

- screwdrivers of different types and size.

The process of installing panels on the wall can be described as a sequence of steps:

- With the help of a construction level on the wall find the most protruding place. From this place is measured by the distance on which the panels will be located. This distance is noted by points on the wall located perpendicularly. To make the frame of smooth, parts of the metal profile are installed using the so-called direct suspensions.

- The next stage of work is the installation of the UD profile guide, which is placed along the entire surface of the walls. The accuracy of the installation during the work is checked by the level. In the same way, the CD profile is mounted on the wall using a direct suspension. The suspension is fixed on the working base by self-drawing, after screwing the dowel into the wall. Details of the frame are combined with short screws.

- Having built a metal frame over the entire surface of the walls, fastening the PVC wall panels. In those places where the outlets will be located, the openings of the appropriate size will be done in the facing material. The first part is set in UD profile and attach it to the CD profile in several places. The next panel is connected from the first, the crying of its protrusion into the shelf of the previous part. Then the material is also fixed with self-draws. Such a way is facing the entire surface of the walls. If necessary, the extreme parts are cut into a sharp knife to the desired size.

- The last stage on the wall mount the ceiling borders and plinth.

PVC wall panels, photo:

Start a discussion ...

Start a discussion ...