A very important above-ground part of the foundation and the lower part of the external walls of the building is the base. It not only carries a decorative function, but also acts as the basis on which the building stands, it serves to protect it from the penetration of moisture and cold. Facing protects the base level from the influence of various external influences. Thus, the choice of facade materials for finishing the base in a private house is the question of not only aesthetics, but also safety. Consider the most popular ways to finish the base in this article.

Purpose of choking finish

Most of the foundation of the construction is hidden from the eyes, however, above the ground level, part of this carrier structure, called the basement, is usually opposed. When planning construction work, it is worth considering that if there is a base with a height of less than 40 cm to equip reliable waterproofing of the walls will be difficult.

Tsocols are usually removed from stone or bricks, concrete slabs, and also poured from reinforced concrete. The stone base looks quite aesthetically and solid, and does not need further cladding, in other cases it will be necessary to separate it to separate it with a suitable material. It should be noted that these work is carried out not only in order to decorate the building. For cladding the base, use facade materials with a significant margin of strength, as they need to perform protective functions. Together with the conservation itself, its cover carries a functional load - it assumes the load from the wall structures of the building and distributes it to the foundation of the construction. It is required that it can withstand pressure and protect the base part of the building from the effects of negative external factors - temperature drops, precipitation, high humidity.

Types of base structures

There are several basic constructions of the base - it can be arranged in a building with a building, act either to fade relative to the surface of the walls. Most often, private houses are equipped with a serving or smooth base unit, although the trees are less susceptible to the effects of precipitation and can serve longer. In the presence of a welding base, it is easy to hide the waterproofing, equip reliable insulation and lining the design by any suitable materials. If there is no basement in the house, the finishing materials of the base part of the building also perform reference functions and take the pressure of the soil, while to some extent support the safety of the entire design. If the cellar is either a basement present, the cladding of the base helps to increase the heat-shield properties of the base level, since in the presence of a cold base, a significant part of the heat will leave the building. If a basement is provided in the building, or if the walls of the construction are not thick enough, the most appropriate arrangement of the protruding base with lowers, since this design will provide additional thermal insulation of the building. The design of the base unit is considered to be the same successful, located in the exterior wall - in the presence of thin walls, in such cases the appearance of condensate and dampness indoors can not be avoided.

Materials for finishing the base

Thus, it is necessary to choose the material for finishing the base with the following operational characteristics:

- reliable grip with the surface of the basic structure, as well as strength to mechanical damage and wear resistance;

- low thermal conductivity to protect the building from heat loss;

- steam permeability, as well as low hygroscopicity - it is required that the finish prevents the penetration of moisture into the foundation and wall structures.

For facial finishing, it is important to avoid moisture transfer. To avoid the appearance of condensate, drowshes, freezing and detachment of the cladding of the base, it will take to apply the material that will ensure protection against moisture and at the same time will not prevent the outflow of the pair of rooms.

The stated requirements correspond to various facade materials.

Currently, the following cladding materials are most popular for finishing the base:

- various types of siding;

- natural or artificial stone;

- clinker tile, polymerpessic, based on resin or stone;

- pVC panels;

- profiled sheet;

- special plastering coatings (decorative, including mosaic, plaster).

When choosing the most suitable finish method, it is worth considering compatibility with the base of the design. For example, facade paint that is suitable for a brick base should not be used for a concrete base.

Finish base plaster

The simplest and most affordable method of finishing the base is its plastering. Nevertheless, such a facing is distinguished by several shortcomings - it is not too durable, besides, it looks not too aesthetically. In mechanical effects, the plaster has a property to crumble, in addition, it is not too effective as protection of the base level and the foundation from the adverse effects of the external environment. Nevertheless, due to its availability, the method of finishing the base plaster has gained wide popularity.

Replacing the usual plaster on its decorative variety (for example, waterproof based on the resin with the effect of shallow mosaic), it is possible to significantly improve the type of base level. The decorative trim of the base allows him to give it a more aesthetic appearance. After applying plaster it can be painted. In addition, with the help of a rashpil, it is easy to give the surface of a freshly mounted plaster, the effect of brickwork, paint the base and highlight the seams with a contrast color. The plastered base can be further fond of finishing material to its taste.

Decorating the base with special coatings

As a reliable protection of the base level, you can choose special coatings for trim. These include:

- facade paints, distinguished by high resistance to weathering;

- special plaster formulations.

These finishing materials are conveniently applied to the surface, but not too durable. Nevertheless, they provide high-quality protection of the base from external influences. Syloxanic plaster has proven well - this finishing material is distinguished by permeability for steam, provides reliable insulation from moisture (including when temperatures drops), perfectly masks the irregularities of the treated surface. This mixture is imposed on a metal mesh-reinforced mesh, a coating can be painted from above.

Finishing the base brick and stone

Traditionally, the base level of buildings are separated by brick. Such cladding is durable and durable. Its deficiencies can be attributed to the high cost compared to more modern ways of finishing (for example, siding and tile), as well as the emergence of a significant additional load on the facade of the building. Clinker tiles, imitating brickwork, uses considerable popularity. The selection of this material allows you to significantly reduce the trim of the base level - as well as it is important, to reduce the weight load on the supporting structures.

Natural stone As a material for facing a concrete monolithic or slab base is practically beyond competition. The decoration of the base of the base provides the most durable, resistant to external influences and a durable coating that looks solid and presentable for many years. According to its taste and dedicated amount, you can pick up various types of stone for finishing the base level of the building - status marble or granite, as well as cheaper sandstone, cobblestone either plate. Natural stone provides environmental safety and has a unique pattern, which can not always be mimic in artificial materials. The shortcomings of such a cladding of the base include its high cost, as well as the considerable weight of the material and complexity of laying.

Alternatively, this natural material can be successfully applied its synthetic analogues, made of concrete with the addition of chemical and organic fillers and dyes. Modern technology allows to obtain cold-resistant, durable, reliable, resistant to moisture cladding material simulating various kinds of natural stone (amorphous or regular shape). Such decoration looks great on the facades of buildings and resistant to various kinds of external influences. This type cladding base differs less weight compared with natural stone and affordable price.

Finishing plinth siding and clapboard

For finishing the basement level of the building is used bunk and block house. Wood Finishing in the form of thin boards (lining), and thin strips of rounded block house provides qualitative soundproofing favorably naturalness and affordable price. Meanwhile, trim the plinth of wood differs noticeable shortcomings - should be mentioned rotting due to the adverse effects of weather, insect damage - in order to avoid such effects need to use special antiseptic compounds. Wood veneer plinth require regular maintenance at least once every six months.

Special types of siding are also used for cladding bases. Such a finish is vapor-permeable, differs by low weight and ease of installation, does not require special care, is characterized by reliability and durability (its service life reaches 50 years). At the same time it is necessary to choose siding for the base. This material is different from the usual wall manufacturing technology and its characteristics, its composition includes special hardening additives. Thus, the decoration of the base of siding can withstand significant loads. It is easy to choose the base panels of various textures (including under the stone or under the tree), in various color solutions. This finishing material can be mounted in any weather, it is characterized by stability to various weather and mechanical effects, not subject to corrosion and burnout, effectively protects the foundation from moisture penetration. Smooth siding panels are easy to install, they will not need to be painted in the future.

Metallising - non-combustible facing material, does not fade and resistant to corrosion, is not demanding of care and allowing the design to "breathe". Vinyl siding is non-toxic and non-combustible finishing material, resistant to a variety of weather influences, insect attacks, as well as the appearance of fungus and mold. With the help of such a modern finish, it is easy to give the cap a neat look.

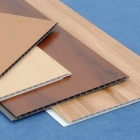

Finishing base panels PVC and straw

PVC panels for exterior walls with imitation of brick masonry or mosaic plaster can be purchased in a wide range of shades. This finishing material is characterized by stability to a variety of weather effects. Such panels are equipped with a groove-cream system, weigh a little. The decoration of the base panels is conveniently installed.

In private homes, the decoration of the basement is also widely used. It should be noted that this material is not suitable for finishing the base level of buildings from the bar or logs, since under the influence of high humidity being subject to corrosion - thus, such a facing can lead to the rotting of the wood.

Finishing base tile

For cladding the base, the following types of tiled material are used:

- clinker tile - such a finish does not absorb moisture and reminds masonry from clinker bricks. Linear dimensions of tiles resemble bricks. Nevertheless, the tile is much thinner (its thickness is within 8-20 mm), and has a slight weight. To simplify finishing work, you can purchase special angular elements;

- the polymer-sand tile is made of a composite material that has proven itself to finish the base level of buildings. Such cladding tiles with imitation of torn stone or brickwork is characterized by moisture and frost resistance and is suitable for any climatic zones, it is enough plastic, does not form chips and cracks. Since this finishing material is characterized by a slight weight, they can be separated by the grounds in the presence of any, including the most lightweight supporting structures;

- the resin-based tile is a facing material with a smooth or corrugated surface, imitating sandstone or clinker brick. Such a tile is characterized by a small thickness (3 mm), as well as considerable flexibility. When finishing the base of this material, it will not be necessary to purchase angular elements, as it can be flexing in the desired way. In addition, it can be chopped with scissors.

Finishing the base level with their own hands

Deciding with the choice of the most appropriate material and preventing the required amount of it, you can begin the execution of finishing works. Most chain finishing options are quite affordable. Depending on the type of foundation of the building, various cladding technologies can be used. If you have minimal skills, these works are easy to perform yourself.

When planning work on finishing the base, you need to take into account the following recommendations:

- it is worth considering that the wooden frame is not distinguished by durability, so it will require replacement in a few years (it will also need to repeat finishing works);

- the trim of the base of the wood house should be performed after the final shrinkage of the construction. In the presence of a pile foundation, you will need to first build a frame fixed on piles from wooden bars or galvanized metal profile, which in the future it is necessary to lay thermal insulation and then insulating from the penetration of moisture finishing material;

- the surface of the brick or concrete base must be prepared, clearing from stains, dust and dirt. It should be smooth - therefore, if necessary, you should knock down the speakers and fill the existing deepening with a special solution. Next, you will need to apply a waterproof primer composition of deep penetration.

Depending on the selection of the finishing material, the following facing methods are applied:

- facade panels, clinker tiles or stone "plant" on a special adhesive solution. As a result of the use of other glue, there is a risk of waiting for cracking and detachment;

- the polymer tile is fixed on a specially constructed crate (in this case, insulation can be performed) or directly on the surface of the base using self-tapping screws;

- thanks to a convenient groove-cream system, the installation of siding will not be much difficulty. It will be necessary to use the construction level to control the laying of the horizontal panels. This finishing material is attached to a predefined shell frame of a metal profile or directly to the surface of the base - with fixing panels on self-drawing;

- natural and artificial stone are laid on cement-sandy solution or special glue for working with heavy tiles. The space between the elements of the finish should be filled with a special solution for narrow or wide seams;

- for reliable fixation of the finishing material on the surface of the protruding base, it is necessary to establish special eaves, otherwise the material may turn due to adverse weather influences.

To protect the trim of the base from the penetration of moisture, the surface of the porous materials makes sense to treat with colorless water-repellent composition (hydrophobizer) - it is applied with a brush or roller. According to the surface treated in this way, water will be drained, not absorbed into it.

Start a discussion ...

Start a discussion ...