Warm, durable, reliable, durable and eco-friendly ceramic blocks belong to the most popular building materials in our country. In this article, we will consider the numerous advantages of ceramoblocks and describe in detail the process of building walls from this material.

What are ceramic blocks

Ceramic brick was used in construction since ancient times and did not lose its popularity to today. Clay, which is the main component in the production of ceramics, is considered one of the best building materials, because it is completely eco-friendly and allows you to create products of various shapes and configurations.

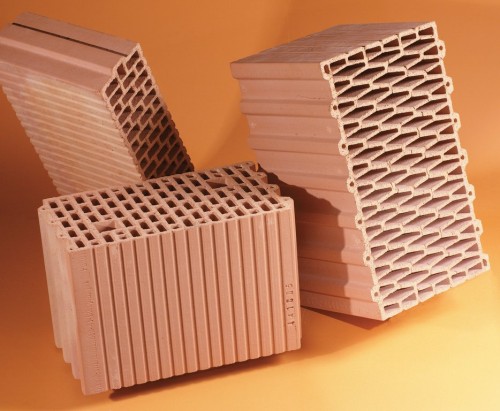

Personal ceramic blocks are a more perfect version of ordinary brick. Such blocks, due to the presence of many internal cavities, have an excellent ability to maintain heat. Porosity also reduces the mass of material, which makes it possible to create quite large parts in size.

Corramoblocks differ from the bricks are also the fact that in the process of their production in clay, some amount of wood sawdust is added. After the finished, but the raw product will be covered in the furnace, the sawmills will be burned, forming inside the void material. Pores in such blocks are also created using a vacuum press. In the end, it turns out durable and solid, but a fairly light and warm building material.

Pros and cons of ceramic blocks

Personal blocks enjoy considerable popularity due to the fact that they have a huge number of positive properties. Consider more the advantages of this material:

- Empties that are formed inside the clay composition after its treatment at high temperature cause a small thermal conductivity of the material, which is reflected in the ability to maintain a comfortable room temperature. Walls from ceramic blocks do not need additional thermal insulation, besides, the hosts of the house from the enrolled blocks can save on heating.

- Such material is very often available in the form of details of a large size, it is logical to assume that the process of laying large blocks will take a noticeably less time than the construction of a wall of small bricks.

- Durability is another indisputable plus material. Corramoblocks retain excellent performance for at least 50 years.

- The small weight of the invoked blocks simplifies the procedure for the construction of the foundation. For such a house, there is no need to create a massive basis that, in turn, will save money, time and labor costs.

- The cost-effectiveness of the material is due, again, its large dimensions. On the masonry made of small brick takes a lot more solution than to build a wall of ceramic blocks.

- The porous structure also performs soundproofing functions, so in a room built from ceramiclocks, it will be not only warm and cozy, but also quietly and calmly.

- Clay - a non-combustible material, so the walls of it are considered to be fireproof. In addition, ceramics are absolutely harmless, does not contain harmful ingredients, even when exposed to very high temperatures it does not release into the environment of any toxic substances.

- From the lungs of porous blocks may be constructed not only the external walls of the building, but the interior partitions. Firstly, the material does not give a big load on the foundation, and secondly, the room in the room will turn soundproofed.

- Ceramic blocks have a good water vapor permeability, so the wall will "breathe", and the humidity in the room will always be optimal.

As you can see, the merits of this building material very much. But do not forget about the shortcomings, below we look at them in more detail:

- The porous structure of ceramic blocks makes them unstable to strong shock loads - this feature you need to consider when transporting material, as well as loading and unloading.

- Keramobloki not hydrophobic, they can absorb water, therefore they should only be stored in a dry place, caution during transportation, preventing wetting of the material in the rain and snow. Using the units in the building, between them and the soil need to provide a good waterproofing.

- Some unscrupulous manufacturers indicate in the product certificate mark, which is not true. If production were errors or inaccuracies can suffer keramoblokov strength, which can be determined only by experience.

Calculation of ceramic blocks

To determine the necessary amount of material needed to make a plan in advance for future construction. It should be noted that the construction of the house on his own project, you may need to examine and modify the size grid. When using the project created by the architectural firm, as well as in the case of the materials typical project size will be a multiple of 250 mm, since it is on this template is oriented most manufacturers porous blocks.

When designing the construction, it is necessary to determine in advance the thickness of external walls and internal partitions. When creating certain types of multilayer walls need to focus primarily on the strength of the structure, proceeding from which the material should be selected size. The compressive strength of almost all types of keramoblokov that are ongoing in the construction market, equal to 100 kg per 1sm².

The process of erecting walls of porous blocks

The subtleties of the process

- Ceramic blocks can not be mounted using ordinary masonry mortar used in work with bricks. need to apply special solutions with good insulating properties to porizovannogo material. Of course, the cost of such adhesive is sufficiently high for the ceramic blocks, but if you choose to save and store the blocks on the conventional cement-lime-sand or cement slurry, the effect of heat insulation qualities of the building material is lost. Solution heat-saving characteristics required in the construction of external walls of buildings, while the internal partitions can be stacked with the use of a cheaper and simpler composition.

- Cooking the mixture may be a masonry cement mixer, and can be used in low speed manual and stirrer. Breeding mass necessary to exactly as it appears on the packaging with the product. The consistency of the solution must be optimal, so it does not fill the pores keramoblokov, but was sufficiently fluid for easy operation. Typically, to prepare 30 liters of solution used 20 kg of dry feedstock.

- When laying blocks on a waterproofing material, it is impossible to prevent damages, so the filler particles in the mortar should not be too large or sharp.

- If you build a house made of ceramic blocks, take into account the weather conditions. For normal operation, the composition with heat-ambient temperature should not be below + 5 ° C. Note that the antifreeze can be useful only in the case of ordinary mortars.

- As in the case of wall construction brick keramobloki are stacked bed using the suture. When the clutch must adhere to its optimal thickness is too thick because the seam will affect the strength of the entire structure, and too thin may lead to the fact that the wall is uneven due to errors in the size of porous blocks. The optimum thickness of the seam is considered an indicator of 12 mm. In this case, the solution to the surface of the blocks must be applied as a uniform layer possible.

- As the load-bearing walls of the building have to constantly load, they need to be spread with the use of solid bed seam. But the internal partitions can be constructed by using a discontinuous seam.

- Those who live in the southern latitudes and does not require the construction of capital insulated home can save on building materials and use keramobloki thinner.

- Personal blocks also reduce the cost of a masonry solution due to the fact that they have the so-called "groove comb" design. This feature eliminates the need for use in the construction of vertical seams, which are mandatory when laying bricks. In addition, such a design reduces the time spent on construction.

Stages of laying ceramic blocks

The laying of walls from ceramic blocks should be carried out in a certain sequence and in compliance with some recommendations. Proper work will help to achieve a good result and get a solid, high-quality building. Consider a phased process of building walls from ceramic blocks:

- Before proceeding with the laying of the paved blocks, it is necessary to carry out waterproofing. This procedure is simply necessary, because the ceramoblocks do not possess water-repellent and well absorb moisture. Waterproofing is laid between the foundation or wall of the basement and the first next to the invoked building material. For such work, rolled materials are best suitable for such a work, for example, the special film, the fragments of which are superimposed on each other, to avoid the penetration of moisture into the gaps.

- The second stage of construction is a horizontal alignment. It is carried out in order to avoid risks of level rejection during the construction of the wall. The operation uses a level or a serpentine level.

- The laying of ceramic blocks start with the corners of the building, where one-piece elements are installed or additional parts are used: halves of blocks or corners. The first series of paired blocks should be carefully checked using a construction level, if somewhere is noticeable curvature, it should be aligned. By the way, before the construction of the wall, the ceramoblocks are better to moisten a little, so that they do not absorb liquid from the masonry solution.

- Before building the wall entirely, you need to post in every corner of the future house for 3 rows of blocks. During the work, you should not forget about compliance with the same level for all items. Horizontal alignment is carried out with the help of a cord stretched between blocks, the verticality is checked by a special plundering.

- During masonry, there is no need to make vertical seams, since the elements are connected with each other using the "groove comb" system. But horizontal seams need to be performed with a special care, following the uniform of the applied solution. The mass is applied to already installed blocks with the help of a trowel, then smoothed the solution over the entire surface, following it, so that its layer was the same everywhere and accounted for about 12 mm.

- Despite the fact that during the masonry of the ceramoblocks, vertical seams are not used, the elements are connected to each other firmly and hermetically. So that the solution in horizontal seams is uniformly, the blocks are first combined with the grooves of previously laid items, and then pressed to the solution.

- In the process of work, one horizontal level must be observed, for this, the cord is stretched between the corners of the building, and each laid block is equal to the rubber image.

- After the corners of the structure are installed and leveled under one level, you can build a whole wall. The masonry of each new row should start from the corner.

- So that the wall was solid and durable, in the process of its construction you need to use the principle of ordinary brickwork, that is, the joint between the two blocks of the lower row should have to be at the middle of the upper row block.

- Simultaneously with the construction of the outer bearing wall, an internal supporting structure should be erected. The walls are connected to each other using the internal blocks that are inserted into the outer wall of about 15 cm in depth. If the inner partitions will be built later, when the exterior walls are erected in the planned locations, it is necessary to make a shifter.

- Where the inner walls are connected to the outer, it is better to pave an insulating layer of foam.

- When the bearing walls are ready, you can build a simple one. They are additionally equipped with steel anchors that combine the design with the bearing wall. The ends of the anchors are inserted into horizontal seams of simpleness and carrier wall.

- If the project of the house does not allow the use of only one-piece elements in construction, the blocks will have to be short. For these purposes, it is best to use a diamond saw or a manual saw with an electric drive.

- Fragments of whole cerarmoblocks cannot be installed in the corners of the construction, it is best to lay them in the middle of the structure. In the process of work, it is also impossible to forget about the vertical seam, which should be shifted in relation to the previous row at least 4 cm. By the way, since at least there is no "comb-groove" system on one side, it must be connected to a neighboring element when Aid of the vertical seam made by masonry solution.

- Window and doorways are conveniently performed from the soults of the ceramoblocks.

- Since the porous material absorbs water, it needs to be protected from precipitation to the roof, covering the upper part of the walls with a waterproof film.

On average, no more than an hour of time goes on the construction of 1 m² of walls from ceramic blocks. This is due to both large size of parts and a special "groove-crest" system at the ends of the blocks.

Ceramic blocks, photo:

Start a discussion ...

Start a discussion ...