Recently, artificial decorative finishing stone has become so popular that they are separated by not only the facades of buildings, but also indoors inside. It is about a wild artificial stone for interior decoration today will be discussed, and more precisely the manufacture of stone wallpapers with your own hands at home. I'm already about six months are fond of stucco from the gypsum (here you can see the first job bas-relief), and for completeness of my picture

the bas-relief lacked artificial stone. Searching on the Internet, I found that the prices for stone wallpaper bite strongly, so it was decided to purchase a plastic form for an artificial stone and start making a facing stone on their own, especially since the material (plaster and kel) are sold in almost every building materials store. When the form came by mail, I was already stuck with a gypsum of G6, a red-brown kel, and immediately began the manufacture of artificial stone from plaster.

For polyurethane form, a special stand is required, and it is simply necessary for plastic. Therefore, the husband quickly from thin rails built me \u200b\u200ba stand under the shape. Well, I began to work.

First, the shape installed on the stand, then a brush took several smears in the form of a red-brown color. 0.5 liters of water requires 1 l gypsum. I measured a liter glass. In the bucket poured water, the plaster added and 0.5 h. Spoons of the Koller. The whole mass was well stirred and poured into a form, slightly shaking, so that the solution is growing evenly.

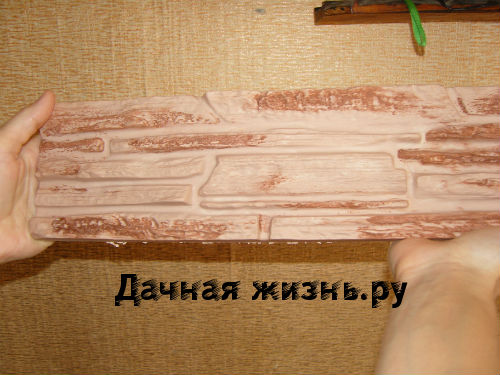

Within 10 minutes, the gypsum grabbed and I shifted the form to another stand, and its place placed the following shape for the stone. Etc. Kneaded, poured, waited 10 minutes, shifted. As a result, for an hour I made 2 k.m of facing tiles under the stone sandstone. From the forms of gypsum tile took out when a ringing knock (as a porcelain) was published about it.

Due to the fact that the kel added immediately when sheltered, I did not have to twist the interior of the gypsum. If you are going to make a facing stone with your own hands, I recommend making coloring pigments at once, since the subsequent painting is not always successful. And with accurate mapping of all materials, with each kneading, the tile turns out to be less homogeneous.

To remove an artificial stone from the gypsum from the shape, I pulled up and towards one edge of the form, holding a stone for the middle. Then the second side, the third and fourth. When the gypsum is frozen, it is very easy to get it, but if it is still warm, then with an early removal from the form you can break the stone. Therefore, the exposure time is very important.

By the way, the composition of an artificial stone of plaster can be changed, making coarse sand instead of 1/3 gypsum. So the plaster saves and the stone is more durable. But I did not use the sand, because the laying did not do not on liquid nails, as everyone is recommended, but on the gypsum putty. She also rubbed the seams. It seemed to me that the gaps between the stones look not very attractive, and I simply lost them with a tassel with a putty, in which a few droplets of a red-brown flatter added.

To make faults on the stone, I chose long pieces from each tile (good, when the plaster is still warm, it is very easy to do, it is cut by the ordinary stationery knife), then neatly put them on the putty and the edges shed.

As a result, it turned out exactly what I wanted to see: a smooth wall, the bottom of which is decorated with a decorative stone.

In fact, the production of decorative stone from plaster is a very simple case with which any person will cope with. And since prices for this type of decorative finish pretty high, I consider it reasonable to buy a form for an artificial stone and make it at home with your own hands. My work on interior design with artificial stone can be viewed here http://kobzewa.ru/category/iskusstvennyj-kamen There is not only thin-layer sandstone, but also a Venetian old brick.

Please give the address where you can order by mail the same mold like yours.

How to order this ETU form ???

How to buy from you such for the manufacture of tiles ???

I do not use such forms already (they came into disrepair), produced silicone, they are more practical, it is easier to work with them (get the gypsum stone) and they are much longer serve.

And where did you buy such a mold ??