Choosing waterproofing material, it is advisable to pay special attention to the degree of its strength, stability and durability. These are the very properties of the characteristics that will prompt you how the material you choose is relieved and how long it will last you.

Content

What is geomembrane

Geomembrane is a building material for insulation made from a polyethylene base with the addition of different additives that give it additional properties that stabilize various chemical reactions and temperature modes.

This is a universal modern building material, which has the most effective properties of waterproofing and drainage materials.

What made geomembrane from

The manufacture of geomembrane is carried out from polymers of high-quality fiber structure, characterized by reliability, durability. In addition, in the composition of this insulating material there are various inclusions of stabilizers that improve its characteristics that give it an additional degree of resistance to the effects of negative factors from the outside.

The manufacture of geomembran is carried out by extrusion method, due to which the uniformity and uniformity of the properties of this material in two (transverse / longitudinal) directions are achieved.

Types of geomembrane

The basis of raw materials for the production of geomembran makes such materials as:

- Polyvinyl chloride.

- Technicimer:

- hDPE polyethylene (or PND) high density.

The geomembrane of this species is produced from high strength material, but low pressure. Its distinctive features are the density, high degree of strength, physical / chemical resistance. It is characterized by a hard structure that allows you to use this film on the smooth surfaces of large areas in the process of building a variety of tanks, water bodies and drives.

- Polyethylene LDPE (or PVD) low density.

The geomembrane of this species is made of high pressure polyethylene raw materials and low density. It is characterized by improved elasticity properties that do not lose at the lowest temperatures. Its use is justified on the width of permafrost, when the structures of the underground type and landfills are erected, as well as on subsidence.

Between themselves, the geomembrane cannon can differ in other criteria.

By material structure:

- Single-layer.

- Two-layer.

- Three-layer.

By surface quality:

- Smooth.

- Texture.

By type of canvas:

- Flat.

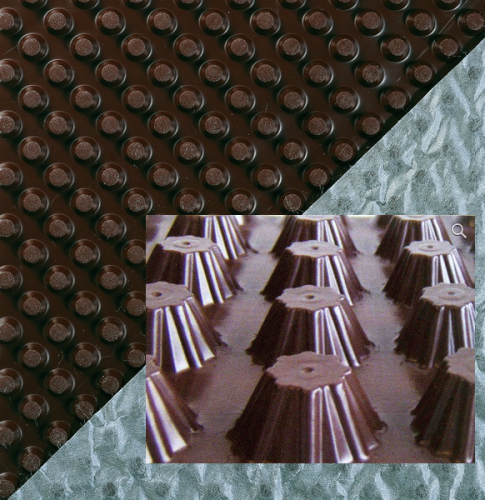

- Profiled.

According to the method of connecting cloths:

- Welded.

- Bonded.

Against the background of this diversity, the geomembrane technolmer is distinguished by persistent anti-corrosion and waterproofing properties. In the process of its manufacture in its composition with small doses and in a certain amount, antioxidants are introduced, as well as various thermal stabilizing additives. As a result, its stability, to the effects of different chemical reagents, the rays of UV radiation and critical temperature fluctuations is very high.

Manufacturers Geomembrane Technolimer produce three main types, this is a polymer sheet:

- characterized by smoothness of both sides.

- characterized by the presence of the anchor ribs, which is provided at the expense of a more reliable fastening it to structures made of reinforced concrete; it is used in a monolithic and heavy construction, in the construction of fixed formwork.

- The composite sheet, characterized in that its base is thermobonded geotextiles.

More information learn by watching the video:

Characteristics and properties of geomembranes

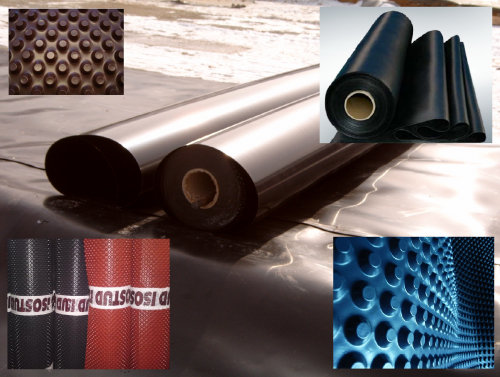

As the finished material geomembrane in shops, warehouses, markets and construction sites are supplied in rolls that are protected by special packaging. The width of the web can be up to 12 m, the thickness of the material varies in the range 0.3-3 mm values. Geomembrane, which thickness is 0.3 mm or more, can be supplied as a sheet material.

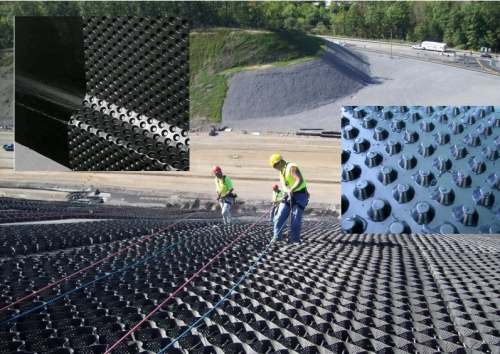

Monolayer geomembranes are used mainly in the field of ecology and hydraulic engineering, welding of its individual sheets in a single web by means of special equipment.

Characteristic differences polymer properties has geomembrane type LDPE and HDPE. It is able to withstand heavy loads and stretch (600-800%) without damage. the period of operation of this unique insulating material is 25-100 years, depending on the type of use.

The installation work is accepted to use HDPE geomembrane 5-meter-wide. With a web width is convenient to work, there are many advantages:

- Reducing the number of welds.

- Reduced material consumption.

- Increased stacking and welding speed.

- Increases productivity and speed of installation.

One team may lay 10,000m 2 5- meter web within one working shift.

Tightness and integrity of its retained for decades. In conjunction with other beneficial properties of the polymer geomembrane offers great opportunities to use it for the purpose of waterproofing in all (including parts / industrial) building areas.

The main advantages of geomembranes

- Resistance to chemically aggressive media.

- The strength of the structure.

- Resistance against punctures and other mechanical damages.

- The presence of high anti-corrosion properties.

- Ability to stretch.

In Europe, the insulating material is actively used in the construction and arrangement:

- sites for storage and solid wastes;

- artificial water bodies (pools, fountains, waterfalls, etc.) on private and municipal lands;

- land (landscape design).

In whatever the construction of the geomembrane, its service life will certainly be not one decade. This material without deformation and damage can safely survive the torrential rains and deep frosting of the soil. It will fully cope with its functions without disturbing the waterproofing properties of the structure, the element of which it is.

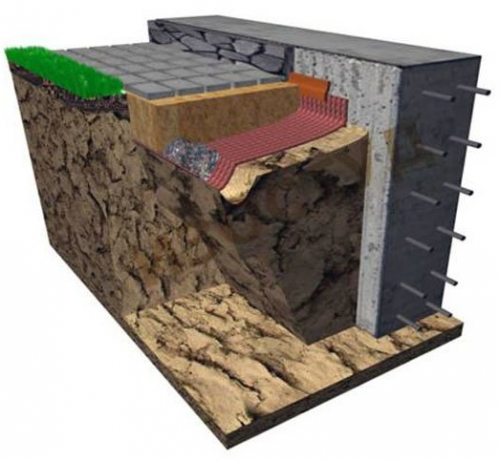

Reliable protection for foundation

In order to secure the foundation of the structure from the negative consequences of the influence of fungi, mold and moisture on it, at the stage of structures, it is necessary to thoroughly consider the system of its waterproofing. Melt water, raindling and groundwater constantly cause him considerable harm, so waterproofing for the foundation should be very reliable.

It is most effective with this task a geomembrane copes, to buy which in rolls or sheets can be in any specialized store or on the site of its manufacturer. This material is unique in that ensuring reliable protection of the foundation from moisture and dampness, it simultaneously contributes to its high-quality ventilation.

Benefits GeomemBran for foundations

There are a number of common and characteristic useful properties:

- Long (more than 80 years) service life, without loss of basic properties characteristics.

- Resistance to the effects of UV radiation.

- The material is indifferent to the processes of rotting.

- Not afraid of temperature regimens, withstanding fluctuations in the range from -40 0With up +50 0WITH.

- The presence of anti-corrosion properties.

- The material is indifferent to the effects of alkali / acid media, petroleum products, abrasive materials, oils and other substances relating to 1 hazard class. This is especially true of LDPE / HDPE geomembrane, which allows them to apply them in environmentally dangerous facilities.

- Sustainability with respect to any mechanical damage, excellent extensibility, non-presidency, flexibility.

- The presence of a unique fastening system and the feature of the structure of the upper layer of geomembrane makes this material convenient in operation. It is easily mounted at the junctions at the expense of a special lock, which greatly simplifies and speeds up its assembly.

- Due to the high degree of elasticity, it can be stacked on horizontal and vertical surfaces at a speed of 2500 m 2 for one work shift. This contributes to a significant reduction in the delivery of the facility.

- The durability of the material and waterproofing is determined by a period of 25-200 years from the installation of the geomembrane.

- In comparison with waterproofing from clay, the economic benefit when using this material is almost 60%.

- As an environmentally friendly and chemically stable insulating material, geomembranes are convenient when there is a task of insulation tanks with drinking water.

In modern conditions, this insulating material is considered the most promising in terms of using it for isolation and drainage of objects / systems.

Geomembrane of a thorough type

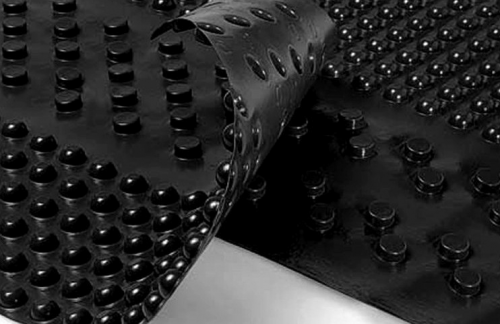

Shipovoid geomembranes are considered the most in demand, the surface of which is equipped with special spikes. Their inner layers of drainage type contributes to their stability to various loads (stretching / deformation) and retains the surface structure.

Possessing the strength of such a high degree, they serve for many years. The unique internal structure is able to reliably isolate the object from noise, air and water streams, ensuring efficient ventilation that meets the necessary standards.

Scope of application

The purpose of the geomembrane is reduced to the creation:

- anti-filtration screens;

- insulating systems.

They are used to build geological barriers that restrain the penetration of various gases, water and other liquids, soil, air.

Its target destination This unique insulating material found in all spheres of construction:

- The tailings on mining and processing enterprises, as well as career, and mine (dumps of useless breeds).

- Slotakers at industrial enterprises.

- Reservoirs / reservoirs / reservoirs (irrigation / amelioration).

- Various anti-beaded buildings, Polder Dams.

- Anglers (on thermal power plants).

- Drives (agro-industrial farms).

- Plopropuscas.

- Reservoirs (technical / drinking water, etc.).

- Artificial reservoirs (ponds / pools / fountains, etc.).

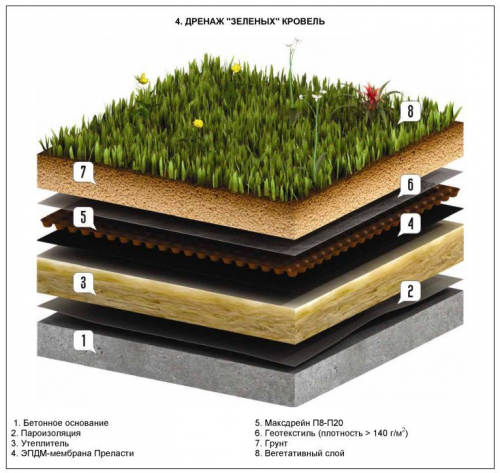

- Drainage systems.

- Mounting foundation Many other types of construction work.

- Laying the pipeline.

- Waterproof dams.

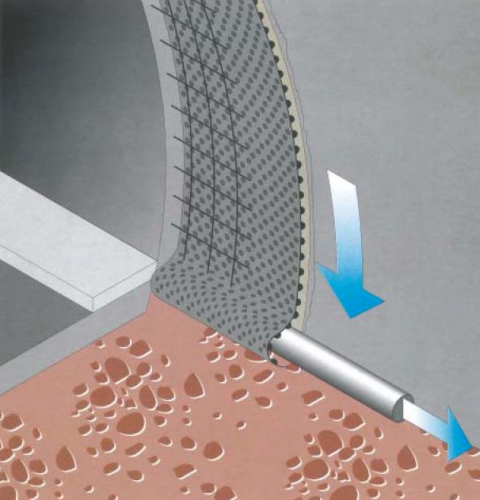

- Road construction (underground parkings, tunnels of various purposes).

- Polygons for waste storage (industrial / household during their recultivation, construction, expansion).

Video on how to properly put and weld the geomembrane on a large area:

Features of the use of spike geomembranes

More often they are used as basic waterproofing or the main drainage layer. Target destination This material found in the construction, industrial production and private sector. It is ideal materials in the works associated with the construction of vertical designs (used drains) and horizontal (reservoir drainage) type. These are underground parts of the most distinct facilities.

Price category

Today, the geomembrane, the price of which refers to the category of average prices, can be successfully used, both in industrial areas and in domestic needs. This is quite affordable material and unique material in its properties. You can buy it in specialized stores or on sites through the Internet, as well as directly (large opt / retail) at the manufacturer.

Laying and mounting

In the process of laying and installing geomembranes, significant problems or large difficulties usually do not occur. There are certain rules for working with this material that should be followed so that no difficulties do not arise. If you doubt your own knowledge of these rules and in your abilities, attract the work of an experienced styling wizard, it will work in a short period of time and will give the appropriate guarantees.

Before working with geomembrane, it is necessary to carefully prepare the basis. Each of his species requires different training, as a result, it is necessary to get an absolutely smooth and clean surface. The construction of any construction object requires clearing the selected area (for light structures) or the preparation of the pit (for foundation buildings). In both cases, at first it is necessary to clear the site, then put the markup of the site and do the necessary earthworks.

Preparation of the foundation

- In the case when it is necessary to prepare a pit for the building, after cleaning the site and land work, its base should be traaming the rink.

- If the selected area is characterized by the presence of a high level of groundwater, it is important to provide in advance by organizing a reliable drainage system to protect the future structure from dampness and premature destruction.

- With the unstable soil on the rammed site, it is necessary to impose a clay castle. The standard base is usually placed sand or gravel pillow.

- At the next stage of work, geotextiles are placed in order to protect the canvas of insulating material from any damage to a mechanical nature as a result of possible soil movements.

- When all layers of "bedding" are prepared, you can begin to mount the geomembrane canvas.

How to make laying geomembrane

No matter how reliable was the material, the life of its operation and reliability, first of all, depends on the quality of its laying. To properly put geomembrane, it is necessary to first make a plan for its laying and rational arrangement of the canvas. Sometimes it is important not to forget the likelihood of the combination of cloths.

So that the waterproofing of the pit was a single one-piece design, it is necessary to consider the disclosure of side, main and angular cavities with a special care. Consider necessarily the fact that all connective lines of the material on the slopes were perpendicularly located relative to the shore of the pit.

The process of laying geomembranes is carried out by manually or using traverses that allow you to perform the rolls of the rolls of the material. Stacking this material must be carried out under certain weather conditions:

- The permissible strength of the wind is within 5 m / s and no more.

- The necessary air temperature should not go beyond the range of values \u200b\u200bof -5 ° C ... + 40 ° C.

- It is unacceptable to lay geomembrane in crude or rainy weather.

Waterproofing concrete base is carried out similarly to the preparation of a land basis. The difference can be considered the technology according to which the laying of geomembrane is carried out on a vertical basis, it is necessary to use anchor bolts for its fixation on concrete.

Each bolt is covered with a special protective patch, which is performed by welding an extrusion type. Vertical seams are stitched by the welding method of the contact, avoiding welds in the corners of the structure.

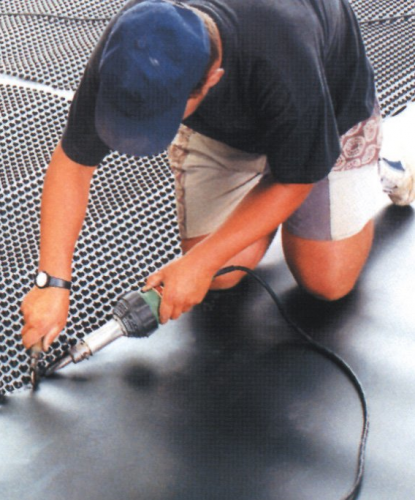

Features of welding geomembrane

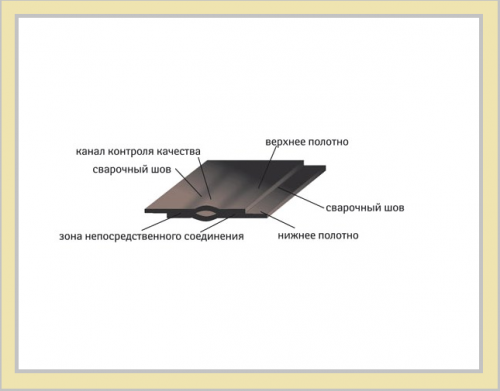

Located in a certain order of the canvases are connected by means of welding. Extrusion / contact welding of geomembrane, which is carried out by means of special tools and equipment:

- Contact welding is needed when connecting linearly smooth designs.

- Extrusion welding is used when conjuncting the canvas in the angular parts of the structure are not allowed for welding.

- Double welding seams need to be checked with compressed air through the test channel to make sure its tightness.

- Welding seams should be checked for a possible gap or possible stretching over the quality control channel.

At the final stage of the welding work, it is necessary to fix the edge of the geomembrane on board the pit, consolidating it in specially trained trenches. For additional protection, it covers on top of another layer of geotextile, on top of this layer can be sprinkled with a layer of pebbles / sand.

Geomembrane can be used in various spheres of human activity, while it has to be laid on different in the quality and structure of the foundation. It is more often styling it is carried out on the reinforced concrete or earth grounds, which (according to generally accepted standards) must be competently planned, cleaned from various garbage and organic organics, do not contain sharp corners, stones and protrusions more than 30 cm.

Geomembrane - reliable, durable and convenient insulating material. The durability and integrity of the design, the element of which it is depends on the quality of its styling, installation and welding. Only specialists, equipped, in addition to knowledge and skills, all necessary tools and equipment, can ensure compliance with all requirements and standards for its use.

Start a discussion ...

Start a discussion ...