The Norwegian construction technology of residential buildings appeared in Russia not so long ago, but instantly deserved an excellent reputation. The developers interested in the Norwegian flaws amounted to and continue to make a worthy competition to firms, elevating houses from a log circle. What is the specificity of the construction of houses from the boiler? You will learn about this and many other things in this article.

What is a laphant

It is not difficult to guess that the technology of the Norwegian boat came to us from a distant cold Norway, the inhabitants of which are known in the methods of housing insulation. This is one of the main reasons that the technology has so quickly and successfully arrived in the frosty Russian climate, especially in the northern regions. What is Norwegian flaws?

Flap is a log, dried in a certain way and processed according to special technology. In other words, the boat is not a log in itself, but a tree processed by manually in a certain style of cutting. This style has been formed in ancient Scandinavia, when the Vikings built their settlements on the shores of the cold seas. No strong northern winds could blow these walls and destroy their strong dwellings. But it became possible not only due to the laphant, but also the nature of the assembly is the Norwegian "castle".

The Norwegian castle or "Sly Castle" is a unique system of joining the fauthete, due to which a powerful deaf wall is obtained without a single lumen. The technology eliminates the occurrence of drafts, freezing the corners and other "classic" troubles associated with the construction of housing from the tree. Moreover, the shrinkage of such a house plays only in favor of the strength and durability of the structure - the stronger the shrinkage, the more reliable the "castle", which means that the whole building is warmer! That is why wooden houses from the boiler choose those who want to settle in picturesque, eco-friendly and warm dwelling for many years.

It is worth a little more about the way to handle the boiler. It appeared in no coincidence, but in order to save. Even the ancient scandinals were known that the larger the log, the stronger and the warmer house. But a thick log and is suitable, therefore the method has been invented, having a large log cabin. A pine log of two ends was cut, the resulting porch was on the arrangement of the roof and floor. Thus, in the work was used without the rest of the entire array. The rafters and the inner partitions were also erected from the boiler. There were no attic in ancient houses from the boiless, and today many prefer to follow this tradition. The roof was plane, meadow herbs grew on it and passed the goats. Grass and Dern effectively defended the house and kept warm in winter. Plus, what to say, it looks like this spectacle very picturesque!

Production of lafeta

Projects of houses from the faucet can be completely different, but often customers prefer a classic option with a flat horizontal roof. For the construction, a forest from 28 to 50 cm in diameter is used. The price of the house from the boiler depends on the project and the log diameter.

The boots are doing this way: first the side parts of the log are cut off, the bark is removed from the remaining semicircular sides. Further processing is carried out manually: the groove on the semicircular part is selected and the angular bowl is manufactured. Previously, it was done with the help of axes, today work facilitates chainsaw.

At first glance, the house from the boiler can be confused with the bar, but it looks more harmonious and powerfully due to the high crown, performed in the size of the original log.

Due to the fact that the raw materials for the boiler are thick logs, it takes much less crowns to build the walls than when the log or brusal house is erected. This is a significant advantage, since a smaller number of crowns reduces the risk of cold bridges, increasing the durability and heat saving of the house.

During the construction of the Norwegian house, special attention is paid to the angular compounds. Because these are the weakest sections of a wooden house, they are freezing and blurred by a cup of everything. There are many ways to connect logs in the corners, but in this case the aforementioned "Norwegian Castle" is used, the advantages of which we will talk just below.

Methods of fastening lafethe

The method of compounding the faucet is determined during the planning, since it determines the nature of the construction structure and requires various approaches. Two types of connections are used to build houses from the boat: "Norwegian Castle" and "Canadian Cup". These are two completely different types of wood processing. The efficiency and efficiency of these compounds surpassed even the traditional Russian technology of cutting.

Norwegian castle

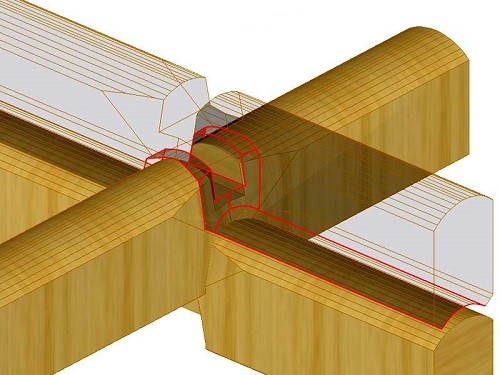

When the "Norwegian lock" is connected, the logs are joined in the "bowl" - a deepening that holds every log in its place. Ends of logs protrude in the perimeter of the cut, which automatically creates protection against wind and makes the angles warmer. Most developers are inclined to believe that this is the best way in humans.

In the bowl of the logs make spikes and opening under it to reduce the penetration of air and the formation of drafts. When a shrinkage of a freshly built house occurs, the internal trees and spikes are squeezed to the limit, so such a "castle" is also called self-clining. The logs are pressed to each other so hard that the need to pry the wall completely disappears.

Another serious moment when using the "Norwegian Castle" - the forest of natural humidity, from which the flaws usually do is not deformed from the internal pressure during shrinkage.

You can do any roof, even from heavy metal tile or to lay Dern and graze goats, as the ancient scandinavians did - a powerful rafter system will endure any weight! Norwegian rafters are built from chopped frontons in all rooms of the second floor. Frontones are connected with each other log system, known in professional circles as "End" and "Horse".

Any dwelling made from the forest of natural humidity will give a shrinkage, for this reason it is necessary to wait out of several months to a year before it is to make the house and start an internal finish. Otherwise, cracks will appear in the logs, they spawn, and all work will go to the Nammark. In the house of the faucet can be settled immediately after the end of construction. The rapid rates of construction and the ambulation of commissioning is another significant advantage of this technology.

Canadian Cup

Another way to process round logs is called "Canadian Cup" or "Canadian Cutting". Special technology allows preserving natural properties and natural structure. Hitching manually harms a strong outer layer of wood, making fauces more immune to environmental exposure.

The main difference between the "Canadian cutting" from the "Norwegian Castle" is that there are trees near the furnaces. The cup itself has a trapezoidal shape. Due to this and the presence of trees during the shrinkage of the house, the angles are as close as possible, while maintaining the heat and a neat overall.

The "Canadian Cup" gives a very accurate fit of the logs, which eliminates the formation of the gaps between the crowns. Thus, the wall of the cut seems to be a solid array, and the insulation at it does not go out and does not pick up moisture along the edges. With this connection, no reuse is also required.

In this video, it is shown how the processing of a log circle on the technology of "Canadian cutting" is:

Benefits of the houses from the boiler

Of all the above, it becomes clear that houses from the boiler (photo) are created for those who want to thoroughly bother on the site and build a house that would serve as reliable and warm blood for several generations.

Today, the trend towards an eco-friendly lifestyle, the thrust for nature, silence and tranquility is manifested in such a phenomenon as a downshifting - people leave close city apartments and move into a suburb and villages. But only little to go away from dusty motorways and factory emissions, it is necessary to secure the most cozy and comfortable life. That is why the houses from the boat are becoming increasingly popular every year. Their advantages are obvious, and quality justifies and pays off all expenses.

Among the main advantages of houses from the faucet can be allocated as follows:

- absolute environmental friendliness - houses are completely made of wood, and even for connecting logs, synthetic materials are not used;

- excellent thermal insulation - durable compounds without the slightest "lumen";

- natural ventilation - even tightly connected logs "Breathe", passing the required amount of fresh air through a natural wood "filter";

- high speed buildings - on the construction of the house leaves from 3 to 8 weeks depending on the project;

- you can settle immediately after the construction - no need to wait a whole year, while the logs will give a shrinkage and dried out;

- durability - the Norwegian house of the bootheette will serve not one dozen years.

Start a discussion ...

Start a discussion ...