Ceramic blocks are a modern building material that combines the traditions of the brick structure and the benefits of new technologies. By heat-saving properties, they can be compared with structural blocks from cellular concrete. A large format and porosity of ceramic blocks are attached to buildings from such material excellent heat engineering, as well as high-quality characteristics.

Types of ceramic blocks

Ceramic blocks are produced in the form of a parallelepiped with puzzle-puzzle protrusions on sides and technological through voids inside. Corramoblocks can also provide round or square holes on the sides for the convenience of laying in the construction structure. In addition to molded voids, micropores are present in the block structure. Gas-air inclusions formed due to firing at high clay temperatures with additives - in places of burning out of wood sawdust and other organic fillers (rice, sunflower husks, peat dust, etc.), give the ceramoblock porosity.

Depending on the method of operation, the following types of ceramic blocks produce:

- ordinary;

- facial, weighing decorative functions - can be painted, with a smooth or embossed surface.

The standard width of the ceramic unit is 25 cm, produced blocks with a length of 25, 30, 38, 44 and 50 cm. According to the technology, the thickness of the wall is determined precisely a length of the ceramoblock.

We produce whole blocks, as well as so-called good (half and angular) - they are used to masonry the corners.

The advantages of ceramic blocks

Among the advantages of ceramic blocks for construction should be noted:

- environmentally friendly - due to the natural composition of the material, as well as production technology, ceramic blocks have optimal thermal conductivity and in buildings act as a natural air conditioner - in such houses will be cool in the summer and not cold in winter. Walls from warm ceramics are characterized by good vapor permeability and provide natural moisture exchange, the effect enhances the porous structure of the blocks. Houses from the paved ceramic blocks are characterized by comfort;

- resistance to atmospheric influences, temperature drops, the influence of aggressive chemicals. Corramoblocks are characterized by frost resistance, as well as antiseptic properties - mold and fungus will not appear on their surface. Such walls are distinguished by excellent sound insulation properties. The air cells of the ceramiclocks are perfectly muffled the sound, the sound absorption of this building material is at least 50 dB;

- high strength and stability of cerarmoblocks in combination with a small specific weight - these properties of the material make it possible to reduce the cost of the foundation of the building. Houses from ceramic blocks are distinguished by efficiency, reliability and durability;

- ease of material processing and convenient volumetric parameters. The largest ceramic porous block replaces one and a half dozen bricks. The speed of laying porous blocks is two times higher compared to the brick wall;

- due to the corrugated surface, porous blocks serve as the optimal basis for applying plaster - it will be required twice as fewer than when the brick wall is erected. Vertical seams are not filled with a solution, dense fixation "in the lock" is carried out using a puzzle system.

Laying of walls from ceramic blocks

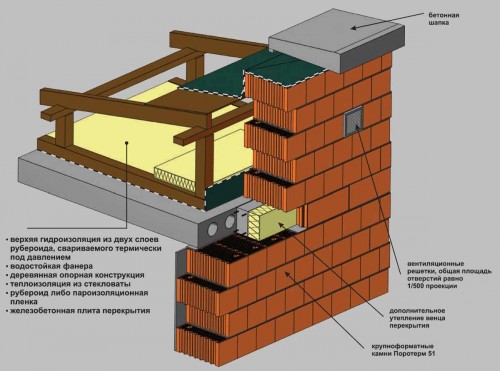

The technology of building walls from ceramic blocks allows you to get a wall with a homogeneous surface, without the presence of cold bridges, shrinking deformations and cracks of plaster.

Preparatory work

When carrying out work, it is necessary to take into account a number of nuances:

- before laying blocks, it is necessary to perform horizontal waterproofing using rolled means on a bitumen basis (for example, rubberoid). The joints of the material are superimposed with no less than 10 cm;

- for the preparation of the solution, it is recommended to use a dry thermal insulation mixture on the basis of perlite - to erect the outer walls into one row, and the conventional cement-sandy solution for the inner walls. It is necessary to pick up such a mixture consistency so that it does not fall into blocks of blocks and easily aligned, with the grains of filler not more than 3 mm and the mobility of the solution is 7-8 cm, a plasticizer is added for the convenience of laying;

- works on the laying of walls from the ceramblocks with the help of a heat-saving solution must be carried out at an air temperature of at least + 5 ° C, the conventional cement-sandy solution is allowed to add contamination additives. Before mounting the roof, the top row of wall blocks should be covered with a film in order to avoid scattering masonry from rain and moisture ingress.

Laying of invoked ceramic blocks

The masonry of the cerarmoblocks is carried out in stages in a certain sequence, taking into account some features of working with this building material:

- the first layer of solution is applied to waterproofing using a trunk or a bucket plaster, it serves to equalize the base in height - for this, a laser or water level is used and a thread (fishing line) stretched along it;

- the masonry of the cerarmoblocks is carried out, ranging from the angles - they use either whole blocks or good elements in the form of angular and halves (or only halves). If you do not care, the whole blocks can be cut into parts. The height of the masonry is equalized by rail order;

- vertical joints of the solution are not needed - they successfully replace the gypsum partition block chaining system. To avoid skewing the blocks are inserted into the grooves of the previous one is fixed in the masonry blocks. Exceptions are cases when it is necessary to connect the side surface with front surface perpendicular to the stacking blocks, or a member with cut. In this case, after applying the solution to the vertical seams must be lightly knock out blocks with a rubber hammer;

- to reduce the water absorption of the cement mortar blocks need to be wetted before placing - by spraying them with water from a hose or dipping the block in a shallow pan with water;

- necessary to build at least three rows of blocks at the corners before the wall laid therebetween while carefully monitor the level of the vertical through angles spanned between the cord-prichalku (it serves as a limiter unit in a horizontal plane and a wall plane);

- full length keramobloki laid horizontally shifted polbloka vertical joints on either 10 cm horizontal joints are coated with a solution thickness of 8 to 15 mm, superimposing it over the entire width of the block, without allowing gaps.;

- internal load-bearing walls erected simultaneously with the outer. Wherein the first number is fed to the inner wall and the outer joined solution in the second row block of the plant on the inner walls 10-15 cm in outer, insulated compound layer of rock wool or foam. If the construction of the interior walls are scheduled to leave for later, it is necessary for them to provide Stroebe;

- after erection of the main walls operate masonry walls - this in the load-bearing walls in the planned locations set galvanized anchors for connection with baffles (a horizontal seams locations).

It should be noted that, for weather protection require plastering walls of keramoblokov - or the use of coating materials (in this case vertical joints it is recommended to handle putty for exterior use).

Warm ceramics and brick materials are used interchangeably - so choosing projects of houses from blocks of ceramic, should bear in mind that in general, they do not differ in layout from the brick houses projects.

Start a discussion ...

Start a discussion ...