Wild stone as a building material is used for quite a long time. It is considered one of the best materials for decoration, facades, garden tracks. However, the wild stone has its drawbacks. It is quite expensive and besides very capricious. In addition, not every natural stone is suitable for finishing, if only because different stones have different strength and resistance. Therefore, it is not always preferred by this material. However, if earlier it was impossible to make it with your own hands, then modern materials and technologies allow it. Through what is now the installation process has become somewhat cheaper. Of course, you can not do everything, but only some types of this material. What kind of wild stones are species, as well as about the peculiarities of its manufacture and installation with their own hands, let's tell you further.

Types of wild stones

Wildstone is also called natural. It happens a few species. Consider more.

Sandstone. This is one of the frequently used wild stones. It consists of quartz particles that are between such minerals as carbonate and ceramzite. Of course, sandstone for some physico-mechanical properties is worse than the same granite. However, it is also quite popular with the facade of buildings facades. The sandstone shade varies from light gray to red, brown. There are blue-gray specimens. This stone is rather durable, which is mainly due to the fact that it has a quartzite. It has an average hardness, low porosity and low moisture absorption. Sandstone is often facing the walls of industrial and private houses. In addition, it is actively used when creating landscape design. It is also used during construction as a substitute for rubble and butt stone.

Ripped sandstone is customary to lay free and chaotic. At the same time, the stones are adjusted with a hammer to each other. If you want the facing to get original, then try to make an asymmetrical pattern. Sandstone is easy to install. It is enough to be put on the cement mortar when, for example, granite and marble require more complex works. Put sandstone without special difficulties you can own it. It is pretty resistant to frost. Therefore, suitable for use in the middle lane of our country.

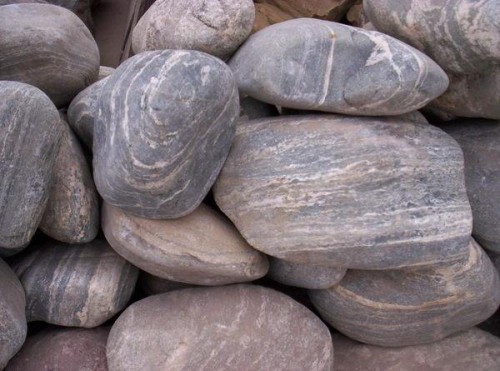

Current stone. Boulders are, in fact, parts of rocks that were subject to water treatment. By origin, they can be river, sea, lake, as well as glacier. Especially valued stones with a size of 15 to 35 cm. As for qualitative characteristics, the boulders differ in frost resistance, wear resistance, durability and durability. They can really live for a very long time. For industrial use, stones are selected by such indicators as breed and size, as well as form and color.

Valun today is widely used in construction. It is used for both internal and exterior finishes. In addition, it is actively used for gardening, stone tracks in the garden, alpine slides. It looks great in the design of waterfalls and fountains. Often, river boulders are combined with sandstone, sea pebbles and granite stone. Perhaps most often this material is used in landscape design. Due to the diversity of shape and texture, you can get a rather original drawing. It is especially worth noting the decoration of the roller veins of the retaining walls of various reservoirs and water slides.

Since these stones are used most often as a decorative element, they must harmoniously look with the rest of the site. In place, he should be located naturally and naturally. To achieve this, it is recommended to choose only one type (maximum two types) stones. Moreover, they must be among themselves to harmonize at least in size, texture, form and color.

If you pay attention to all the variety of such stones, then notice that the bands on them can only be two options - dark and bright. In order for the decoration of the water bodies, the game of light is noticeable, it is recommended to take boulders with different intersions, for example, in the form of suils of mica. It is important to correctly arrange wild stones of this species on the facade surface. Moreover, it is more correct to start laying from the greatest in the size of boulder. Before starting installation work, the material should be viewed from all sides.

With any direction of design, the use of wild stone will be relevant even for inner cladding. Room decorations visually seem to be more comfortable and reliable. Wound stones are often lined with surfaces of walls, columns, gender, as well as external part of the fireplace. Small parts are used as elements of a mosaic, which is obtained by combining pieces of stones of different colors and shapes. This will make the house more luxurious. Many buildings with such a finish can safely be called a real work of art. As a material for cladding, a sawn boulder is often used, which has one of the sides of the flat. Such stones look more massive, but at the same time they are pretty light by weight. Finishing this method allows you to create the illusion of full masonry from cobblestones.

Galka Maskaya. This material is essentially the residue of rocks. The pieces after chopping from a large stone block fall into the water in which they gradually grind and become smoother. Thus, the water makes the most difficult work on making the texture and shape of the stone, and it is no longer necessary to grind it manually. Hence, the conclusion that marine pebbles can be called one of the best natural materials, which is used by designers to implement creative ideas.

It is worth noting that sea and river pebbles have some significant differences. For example, sea usually has a smooth and flat form. That is why it is more valuable as a finishing material. Pebbles in diameter can be from 1.5 to 120 mm. When performing construction work, this stone is successfully used to arrange landscape sites located near the construction. The pebbles are used as a material for garden tracks, as well as for the arrangement of water bodies and flower beds. With it, it is possible to separate the facade part of the building. She is also good because with the right approach, it will be great to look at the premises of any style.

Meotis. This material is also called bakery. It has long fibers in its structure. The stone itself is equipped with an extensive capillary system, which is filled with air. Let us dwell on the origin of this material. In fact, it was formed as a result of the sediments of the shells of ancient marine mollusks. Therefore, it is mined only in certain zones.

It is worth noting that this kind of wild stone is very durable and at the same time plastic. Thanks to the plasticity, it is well processed. It is also fair to compare this material with ceramics. According to some physical properties, they are really similar. Therefore, it, as well as ceramics, is used for cladding and finishing various surfaces. It is impossible not to note the unusual color of Meothice, so there is no need to somehow process it. Thanks to the porosity of the stone, it is resistant to atmospheric phenomena. These properties allow us to successfully use this material for the landscape decor in artificial reservoirs. In particular, it is often used to decorate aquariums.

Independent manufacture of wild stone

Since the wild stone is quite expensive, today they learned him to produce himself personally. What is an artificial stone better than natural? It is worth noting that it is better in some mechanical properties and resistance than natural. But this is not the only dignity. So, this stone can be made in the form of thin tiles, which will reduce its weight. Moreover, its strength will not change. In addition, artificial material can be easily made directly on the site of its future use, so that it is not necessary to pay for transportation.

Artificial stone boasts a variety of colors and surface textures. Today, there are quite a lot of its varieties. They are successfully used for walls, making various decorative items, kitchen sinks, countertops, windowsills and even furniture.

According to the starting materials and methods for the manufacture of artificial stone is divided into several types. Consider a little more detail some of them:

- Ceramic. When producing such stone material is calcined at a given temperature. To set up production requires a lot of space, staff with the necessary knowledge and skills, as well as large amounts of energy.

- Cast. This type of artificial stone is quite possible to do it yourself, and at home. But it is not resistant to low temperatures (at least 17 degrees). Therefore, it can be used for interior decoration only.

- Cement and sand. This type of stone is more expensive than the previous one. But this does not prevent the possibility of its manufacturing at home. For the same purpose for a small utility room. This material is characterized by frost.

- Monumental. This type of stone is usually made individually. Free produced by molding, which makes it possible to make artificial boulders, slabs and paving stones, similar to the natural.

- Polyester stone mineral filler. It is worth noting that with the right approach, its qualitative characteristics can be better than that of some natural stones. This material acquires a toughness under vacuum at high temperature. Therefore, it is virtually impossible to make at home.

- Cast Acrylic Stone. This kind of material can be made at home. If he will harden on a shaker, then the quality of it will be the same as the stone hot curing. An important feature is the possibility to shape the stone after casting, but this requires high temperatures.

- Liquid artificial stone. For its production using gel, acrylic binders. If you compare it with a cast stone, the mechanical properties it is still inferior to him. The fact that the gel can enter less mineral filler.

Production of natural stone. To do this, you need the following materials:

- tile adhesive,

- grout (black)

- part of coloring pigment (red).

Procedure for work:

- The glue is mixed until it turns out a very thick consistency. After that, the resulting mass must be divided into three parts. Two of them add a pigment of a certain shade: to one red, and to another black. As a result, all parts will have different colors.

- When this is done, all pieces randomly need to be arranged on an organote with laminated coating. After that, the product is covered with a thick polyethylene film.

- Now they will need a rolling pin, with which everything should be distributed over the thickness and the necessary format.

- In order to give a stone an interesting structure, you can take a seaside salt that you need to scatter chaotic. After that, everything is needed to cover with a food film and press the salt crystals slightly.

- The next step is molding. This requires only a ruler. Pressing it you can form pieces of any size and shape.

- When everything gets free, the organite should simply take out. As a result, all tiles are separated and retarded from the organity. After that, with hot water, the product is washed.

Laying wild stone

Before starting installation, the work surface must be prepared as it should be prepared. In addition, it is important that strength is calculated. Without this, laying can not be done. After all, the varieties of stone in their composition contain a different amount of sand, enclosures and lime solutions. As for the stacking process, this is a pretty simple task even for beginners. The most important thing is to comply with all the recommendations. The most important aspects of the work will consider below.

Concrete surfaces do not require some kind of special training. It will only take care of the spots of fat and other pollution. If there is frozen paint, then it can be removed using a brush. If there are oil spots, they can be removed by a solvent. Each surface has its subtleties in preparation. For example, wooden walls in front of a sticking stone need to be treated with waterproofing properties. After that, it is still necessary to reinforce the surface with a metal mesh. Metal walls require applying primers before installation. In any case, after preparatory work, you can begin to stick the stones to the surface.

It is possible that the pieces of stone will not be equal in size. In this case, to form the right drawing, they must first be decomposed on the surface. So it will be much clearer where which stone should lie. If you use products of different shapes and shades, it may well be a unique picture. And he will be close to natural.

It is worth saying that the desired ornament is unlikely to work from the first time. Therefore, if not everyone, then many pieces of stone, will need to be rearranged until the result comes out that you will arrange. A small advice: when drawing up the ornament of stones, alternate small and large parts. The drawing thus obtained will be particularly good to look.

If there is a low temperature on the street, then laying it is better to postpone until it becomes warmer. The fact is that the glue used will freeze, and will not freeze. Because of what the pieces of material with a rise in temperature can simply disappear.

Laying wild stones with their own hands is similar to the installation of ceramic tiles. Cement, sand and binding ingredients are mixed for the preparation of the solution. Sometimes stones are fastened more reliable, bitumen mastic is introduced into the composition.

Punching material is carried out using any tiled glue. Often, cement mortar is used for this purpose. But still it is recommended to buy a special mastic that can be easily purchased in any construction store. Slices of stones on such mastic can stick to the working surface pretty quickly. You can also in the first quarter of an hour to tear off the surface without much effort. After about an hour, the coating will be ready, but it will still have to be corrected.

Of the disadvantages, you can call the high cost of mastic. But in fact, its consumption will be less than the flow of other means. For sticking material, it is enough to apply a layer of 2.5 mm layer. No matter how it is distributed, it is important to ensure that the side with the adhesive composition does not hit the sandstone surface. Otherwise it will be very problematic to clean and launder.

In some cases, installation corners are used when laying useful. So, for example, with their help, it is convenient to smooth out uneven angles. These corners are simply inserted into the glue mix layer. And only after that the pieces of stone are stacked on top. Such a mounting corner will be able to easily lie down to the facing material and will be firmly fixed by frozen together with the solution. When the mastic is applied, the pieces of stone should be carefully attached to the working surface and press a little. The masonry itself is more convenient to start from the bottom row.

Wild Stone: Photo

Start a discussion ...

Start a discussion ...