The goal of sound insulation is to reduce the noise level entering the room outside. The ability of constructions to sound isolate is calculated in decibels. From how much the construction rates were met when erecting a house, and what neighbors surround you, it depends, whether you need additional sound insulation of the door, and what it should be.

What is the sound insulation?

The normalization of the noise level in the residential room is determined by the gtales and is subject to measuring with special devices. So, from 7 to 23 hours the level should not exceed 40 dB, and from 23 to 7 hours - 30 dB. For comparison, the power of a common conversation is 45-50 dB, a human cry - 90 dB.

Excessive noise pollution reduces attention and slows down the reaction, adversely affects the central nervous system of the person, leads to irritation and various diseases. Therefore, the hygiene of the residential premises should include high-quality sound insulation of both walls and doors.

Soundproofing doors are those that, due to the noise absorbing filler, all sorts of thresholds, urgent and hermetic fit to the doorway, significantly reduce the noise level.

Soundproofing the door makes sense only when the insulation of walls and overlaps is performed along with it. For example, if in the apartment or house walls from drywall, then, no matter the door, and everything will be heard.

It is believed that, the thicker and the dense door canvas, the better he has sound insulation. This is true, because the array of oak or pine is noticeably reduced the noise, along with fire-fighting doors, where the heat insulator performs the function of the noise absorber.

What are the soundproof doors?

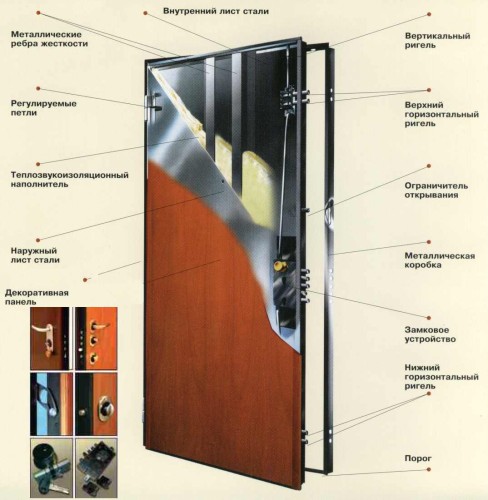

The usual door made of cardboard cells delays only a few decibel, and the standard door from chipboard or MDF eliminates noise to 30 dB. The steel door, without a layer of the insulator, is able to even enhance the volume. What to do when there is a need to effectively protect against noise, say, in recording studios, medical office? There are special sound insulation doors. Outwardly, they do not differ from ordinary, but inside like puff pie.

Finnish soundproofing doors of the company Alavus are covered with painted MDF, and inside them there is a pressed mineral wool. Suomen Ovi produces sound insulation doors from painted MDF with a hearth-chipboard, from two sides of the touched film. Such firms as "Westag & Getalit" (Germany), Parsal (Russia) are known in this market with their laminated models.

By the way, the German manufacturer's doors are equipped with an automatic threshold: a magnetic rail has been recessed into the floor, and when the door closes, it attracts a metal plate located in the door, filling the space of the threshold.

If the goal is to reduce noise in the residential room, when its permissible level is exceeded outside and repay the source is impossible, it is worth trying to make the door sound insulation with your own hands. Most used ways:

- The upholstery of the door leatherette with the lining of one or more layers of foam rubber or batting. The thicker will be a soft layer, the smaller the noise will miss.

To enhance the effect, the door is supplemented by chipboard sheets or furniture shields and rummaged on both sides. In this case, due to its gravity, the load on the loop increases and need to provide an additional loop. - The second option is to be installed two doors with a small tambour in the middle: the air layer and two canvases will reduce the noise level. Often, two ordinary doors installed with a tambour turn out to be more efficient than one sound insulation.

- The effect of reduction of noise to 40% is achieved with the help of special sealing pads that are attached to the door so that their protruding part covered the gap between the box and the blade. Well showed themselves rubber seals firms "FOMESTRIP" (Germany), "Varnamo" (Sweden).

Materials that are activated for sound insulation

According to the unlawful rule on the Internet, the concept of "sound insulation" and "noise insulation" were divided, where the latter concerns only the automotive themes. It so happened that the technology of noise insulation of the doors of the car went far ahead, largely due to new materials. Therefore, it is quite advisable to appeal in this case to some of these materials and apply them in sound insulation of the front door. In the instructions discussed below will be used:

- Sound-absorbing mineral wool company Rockwool Acoustic Batts. The homogeneous fine structure of chaotic fibers, due to air bubbles in the micropores, creates a sound absorbing effect.

- Vibrofilter is a new material for noise insulation, such as the German company "Baumuller". It has a multi-layered texture where the biologically neutral bitumen layer and aluminum foil is included. The vibration filter contributes to sealing, prevents corrosion and does not react with other construction materials, and due to flexibility perfectly falls on any surface. The material perfectly transfers the temperature differences, which makes it possible to use it in the outer door. For cars, his sheets are trying to do as thinner as possible, but in our case it is noncritical, and therefore you can take the cheapest material, for example, bimst. As a damper of vibrations, in the door it will noticeably reduce the sound from turning the locks.

- Splin is perhaps the most used material in automotive noise insulation. Being in the essence of the acoustic foam, it creates a labyrinth effect for a sound wave, which, falling into it, loses the output and quenching. At a low price, it perfectly reflects the sounds, being, besides, and the heat insulator. It has a special adhesive layer, thanks to which he is tightly to the surface. The doorway pasting sheets of the greatest size is a simple and fast process. The thickness of 4 and 8 mm is produced, we take the one that is thickening.

- The last thing you need is the material of the trim. It may be artificial upholstery, which is used for furniture upholstery; Completed on a synthetic or tissue basis, it is resistant to abrasion, breaks, atmospheric and chemical influences. And it can be MDF panels. It is important that it is not the hollow plastic lining, but the paper panels that are covered with vinyl or paper film. Of course, the vinyl option is more reliable.

Soundproofing of interroom doors

Before starting work, most likely, you will have to change the handle and enhance the door, adding additionally two hinges. The fact is that at the end of the isolation, the door canvas becomes much thicker and harder, so its design should be quite strong.

Additional loops are placed near the relatives at a distance of 3-4 cm.

- Soundproofing begins with the design of the sealing roller, which is adjacent to the hole. To the bottom of the open door along the entire length of the stapler fasten one side of the bottom leather strip 15 cm wide (depending on the width of the lumen).

- Cut off the strip of foam rubber, attach it over the leatherette.

- To the lower part of the door, weient the second edge, thus getting a soft threshold damper.

- For further noise insulation, remove the handle with adjustments.

- Cut the sheets of vibration filter, tearing off the protective film and glue them to all the door canvas. Carefully smooth the material.

Important: All soundproofing layers are hiding with a gap of 1.5-2 cm from the edges of the door. This is necessary for the subsequent attachment of the upholstery material and the sealing roller. - The second layer is glued with a noise absorbing material - it is an acoustic foam.

- Next, we carry out the usual soft upholstery from the foam rubber, which is attached using a construction stapler around the perimeter of the door canvase. You can choose the thickness of the foam rubber, usually it is about 2-3 cm.

- The leatherette fastener first in the center at the top, then in the center below. When a vertical fold was formed along the door - the dermatin stretches correctly. Hats of decorative nails better pick up the color of the handles.

- Next, stretching, fix the upholstery on the sides.

- Return the handles into place.

- The last step is to eliminate the slots around the perimeter of the door box. For the manufacture of rollers, we cut similar to the bottom, the leatherette and foam rubber strips - for two long and one short side.

- On the door frame, the stapler fasten one side of the strip, we put into it the foam rubber and wrap, fixing the roller with decorative nails.

Soundproofing the front door do it yourself

- From the inside of the front door, we unscrew all the external pads of locks, eyes, pens. Tip: Put the handle in your pocket and keep it there until the end of the work. If the door will shortly slam, you can open it.

- Upholstery, as a rule, holds on nails with a decorative cap. With a flat screwdriver, we use a nail, slightly pull it out, and then stretch the passage. Collect them in a jar, as they can be used for further work. We also dismantle the roller from the leatherette around the perimeter.

- We disassemble the slabs of the fiberboard or organic, which are usually under a soft upholstery, and remove the entire soft filler or felt. We also purify the outdoor part, we must appear "naked" door leaf, more often it happens metal.

- All sinuses that are available between the box and the wall are placing the mounting foam, and the gaps are shuffled with a thick layer of silicone sealant. Unfortunately, sound insulation the box at home is very problematic.

- We purify the inner surface from the garbage and degrease the surface of the metal moistened in any solvent with a rag (gasoline, kerosene, acetone, etc.) is suitable. If there is a rust, it is desirable to sand it. When working, be sure to use gloves.

- Crow vibration filter depending on the design of the door. For it gluing to the metal, the surface must be heated. A typical hairdryer or fan heater warming the door of the door, and the pieces of vibration filter, meanwhile, can be put on the battery.

- We remove the self-adhesive layer and carefully smooth out the material on the surface.

- The remnants of the vibration filter can be saved the transverse rails of the door leaf and the space around the locks.

- Over glue acoustic foam rubber sliced \u200b\u200bon structural pieces.

- Stage finishing. We define whether the old one will be returned to the place, the new leatherette stretches or it will be the MDF panel. If it is the old sheathing, then its chances need to be pre-straightened with two rivers and clamps.

- It is necessary to pay attention to the holes in the metal around the door perimeter. Under them are the bars, to which the organity is attached. Making sure that the wood did not fade and do not deteriorate, screw the plates with screws.

- We fix felt and return the old upholstery to the place with nails, doing the slots for locks and pens in the nested materials.

Note: A weighty door may not so easily slaughte, as before, so you may have to slightly pinch the box in the area of \u200b\u200bthe response, so that the door is free to close freely and falls into the handle tongue. - To avoid drafts and rattling around the perimeter of the door leaf, it is worth purchasing a D-shaped seal that is sold at any economic store. If you got a paired version, divide it to single stripes. The adhesive layer in such seals is unreliable, so use additionally gel super glue.

- One circuit is glued around the perimeter of the box, and if it is not enough, then the second is glued in front of it, but already around the door. IMPORTANT: Seals must coincide, but do not interfere with normal handle tongs in place.

If it was decided to sew the inner side of the MDF clapboard, then the panels on the self-tapping screw and liquid nails, after which we thoroughly seal through the contour. It is possible to give such a coating to such a coating, simply opening it with the usual lacquer for wood.

There is a second option of sound insulation of a metal door when additionally mineral wool is placed on top of Splann.

Tip: Through the wool, we drag out several electrical wires, place them from the castle and to the top loop, as well as two wires and twisted a pair of eyes to the top loop. Now they do not need to output them, but if you want to put the video recorder, an electric lock or camera in the eye, it will only be enough to drill a hole and pull the wire. In order not to forget how they are stored, take a picture of their location before installing the finish panel.

Start a discussion ...

Start a discussion ...