To date, many insulation materials are also invented. Most of them can be used during the repair work performed with their own hands. Warming methods are quite simple, no special qualifications are required for work. Therefore, mainly the insulation of the floor of the Cold attic can be carried out independently, although some stages of work are quite laborious and implies weight lifting.

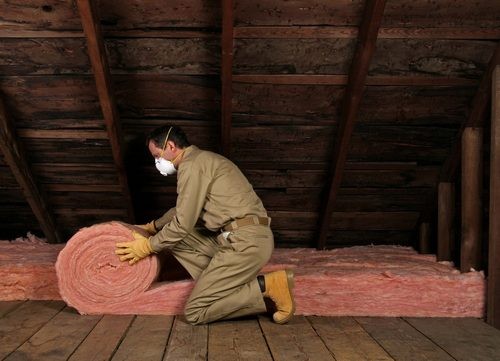

In addition, when working with some insulation (for example, mineral wool), it is necessary to take care of the means of individual skin protection, since contact with the insulation causes irritation. We need rubber gloves, respirator, glasses and clothing, protecting all open areas of leather. Experienced builders recommend utilizing clothes after the end of all works.

A little about the laws of physics

As is known, the percentage of moisture in warm air is higher than in cold. In case of incomplete heat insulation, the attic warm air in contact with the ceiling, cooling, will highlight condensate. On the ceiling and walls will necessarily appear spots of moisture if the indoor of the attic was not well insulated. To avoid the appearance of moisture clusters on the ceiling, it is necessary to observe the correct sequence of the warm-attack of the roof.

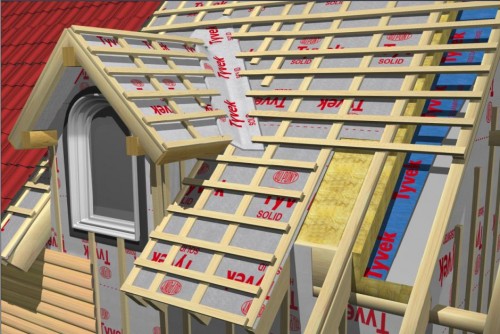

General insulation rules are similar to different types of insulation. Typically, the sequence is as follows: a steamproof layer, insulated layer, windproof layer. If you plan to use the attic as a residential premises (attic), then after laying the insulation, the overlap can be sewed with sheets of plasterboard. Then the floor ripped with plywood or polystyrene foam plates.

However, for different insulation, there are some label nuances that we will consider in this article.

We took care of all categories of our readers who want to exercise a cold attic: video for those who do not like to read the instructions.

Preparatory work

For movement in the passage of the attic, wooden flooring is arranged, because in the layer of thermal insulation it is impossible to walk. Before proceeding directly to the insulation of the attic, it is necessary to produce the following preparatory procedures.

- The most important thing before insulating the attic - to carry out waterproofing and thermal insulation of the roof.

- If the attic has already been insulated, check the condition of thermal insulation. Digitable or moldy thermal insulation must be disposed of. An attic to be disinfected by antifungal agent.

- It is necessary to carefully check the rafters, the fronton and overlaps for the presence of cracks. In the case of an obscure state of the elements of the attic, it is strongly recommended to shake cracks or completely replace some details.

- The slots can be sealing pacles wetted in a lime solution. You can also close the gaps using mounting foam or sealant.

- All wooden parts must be covered with flame retardant means.

- Particular attention should be paid to the state of the ventilation system. To avoid clusters of condensate on the ceiling, ventilation should be carried out. It may be necessary to build additional ventilation channels.

Do not forget that the hatch in the attic - you shave in insulation. Therefore, in addition to the warming of the overlap, you should take care of the insulation of the hatch to the cold attic. It is usually enough to make two insulated covers. The main thing is that they closed hermetically.

Insulation polystyrene foam or foam

The polystyrene foam is similar to the foam, but its strength is higher. The principle of insulation is the same as for other insulation: the bottom of the vaporizolation, then the layer of polystyrene foam, and from above the windproof layer. To lay the foam, it is necessary to arrange a crumpled crate, into which the plates are then tightly inserted. The polystyrene foam is usually produced with groove-cream locks that allow you to put the plates of accurate jack, without through seams, that is, without the device of the crate.

The disadvantage of foam is its rigidity, and, therefore, the inability to put the jack between the rafters to eliminate the formation of "cold bridges". The problem is solved by the use of mounting foam for cracks. Another disadvantage of foam is its fire hazard.

Mineral wool insulation

Starting the work on the warming insulation of the cold attic of the Minvata follows from the far point of the attic room. From the bottom it is necessary to lay a layer of vapor barrier (for example, a polyethylene film, foil, and better than a special membrane) Vansel. Be sure to cord the seats of the joints of the vapor insulating material with hermetic glue.

Mineral wool is stacked on a layer of vaporizolation. Plates of mineral wool from the cornice are installed on the edge, which helps protect horizontal sheets from the wind. Mineral wool must be tightly fitted between rafters.

If the attic is purged, on top of the mineral wool layer, it is necessary to position the steam-cutting layer of the additional insulation, for example, Iosospan A. Do not lay steam barrier from both sides of mineral wool. Otherwise, the moisture will penetrate into the layer of heat insulation, while inevitably the appearance of mold, and as a result of the damage of the insulation.

Warming with clay

Usually, this material is used for overlapping, which is made of concrete, since wooden floors may not withstand the weight of the desired layer of the heat insulator. For the attic of the attic on the attic, a layer of clay, 25 mm thick can be poured on top of the cement layer. The screed must be sufficiently dense by consistency, so that cement does not glare inside the clamzite layer.

If the attic is not used as a residential premises, then the insulation of the cold attic ceraims is needed by a general scheme: a layer of vaporizolation, a layer of claympsit, a layer of wind insulation. The thickness of the clamzite layer must be at least 15 cm, and in some cases up to 60 cm.

Some builders recommend mixing grazit with sawdust, but it should be considered that sawdust is a marked material.

Warming with rolled insulation

Currently, domestic and foreign manufacturers provide a market for insulating materials by specialized rolled insulation. They are made on the basis of basalt raw materials, possess high fire-resistant. The industry produces insulation with windscrelaries, vapor-permeable or steam-consuming properties that need to be used and combined with each other according to the instructions.

Rolls of thermal insulation material are usually fitted with a foil side down. The heat insulation material should be laid continuously. Gaps are not allowed in thermal insulation. Otherwise, air flows form the so-called "cold bridges" and the general system of household houses will be ineffective.

On the perimeter of the attic at a distance of 1-1.5 m from the outer walls having produced, the thickness of thermal insulation is recommended to be increased 1.5 times. After that, the thermal insulation surface must be covered with a windproof plate. You can use a vapor-permeable membrane or a layer of foam (stacked tightly, the intervals fill in with mounting foam).

Insulation polyurethane foam

The polyurethane foam layer is sprayed on partitions, roof, frontoths. Hearth overlapping a cold attic polyurethane foam guarantees the overlap material. Additional strength, rigidity and protection against affected by mold fungi.

The advantages of this material is:

- simplicity and convenience when applied;

- the thermal insulation layer is monolithic: without seams and joints;

- light weight of the insulating layer;

- you can use for different types of floor materials: wood, metal, brick;

- low thermal conductivity: due to this layer of thermal insulation, it turns out to be thinner, which saves the useful attic area (in case of use under the attic);

- perepecility: moisture does not penetrate the polyurethane foam layer, therefore, the attic and the house are protected from condensate.

The only disadvantage of this material can be considered its value. However, many believe that the high price subsequently pays off due to an increase in the term of use and savings on additional materials for vapor barrier.

Warming sawdust

For insulation of a cold attic sawdust, it is necessary to observe the following condition: the attic materials must be vapor-permeable. It is impossible to use polyethylene, rubberoid, only.

The solution using sawdust is laid with a layer of 20-25 mm thick and tamper. The plywood, board or fiberboard is placed on top. From above sawdust, cement screed with a thickness of 5-10 cm.

For the manufacture of a solution with sawdust, you need to take ten bulk parts of sawdust, ten parts of water with an antiseptic (soap, copper vigor, and others), one piece of cement (brand at least 300), and one piece of lime-puffs.

If there is no access to the attic

I also want to say a few words about how to produce a ceiling insulation in the house with an inaccessible attic. Cold attic in this case can not be inspired. With this method of insulation, the height of the room will slightly decrease. It should be adhere to almost the same order, as with the insulation of the floor of the attic (from the bottom up): a layer of vapor barrier, a layer of insulation, but the upper layer should not be parreroping, but vaporizing.

Phased this process is carried out as follows:

- the ceiling is recorded by the membrane of the parobacker with the use of glue-sealant;

- it is fixed to the ceiling a wooden lamp (enough to arrange the rails every half meter);

- polyfoam (Minvata or other insulation) is tightly inserted between the rails;

- the glue is fixed by another layer of the steamproof membrane.

Warmed rough ceiling ready. Decorative ceiling - stretch or PVC panel, or plasterboard. Winter with comfort!

Start a discussion ...

Start a discussion ...