Floor screed is an additional layer intended for equalization of capital overlap, as well as floor strengthening or giving some particular shape. Filling the floor screed is necessary when the device of the "warm floor" system is performed, and absolutely no matter what type of heat carrier you have chosen. This procedure is necessary and in cases where all necessary construction technologies have not been followed during the construction of the building. If the building has wooden floors, and laying the tiles, then the screed will be needed in this case. With everything, at the same time, the filling technology of the floor screed can be diverse - it all depends on which the construction team is haunting the task and what type of overlap.

Filling the floor tie: where to start?

- Before you begin to work, it is necessary to determine the level of the upper surface.

- As far as high-quality builders are suitable for work performed, the floor will be so durable and smooth.

- Before checking the level of overlapping, it is necessary to remove the coating, which is available: either to the capital overlap or before the beams responsible for the inter-storey overlap.

- In order for the work to be high quality and moved faster, use the laser level only.

- The laser level should be positioned in the middle of the room - its rays should be 3-4 centimeters above the surface of the overlap.

- Cement coating should not be more than five centimeters.

- The laser level is equalized by the horizon by the usual water level - it is built into the device.

- When you rotate the level around the vertical axis, the ray must consistently mark all the points on the wall.

- In average, the discreteness of the turn should be no more than 15 degrees, or even no more than 10 degrees - at a time.

- Together with the mark on the wall, it is necessary to install vertical beacons - due to this, you can place the floor level marks both on the walls and in space.

- In the event that the overlap is made of concrete, it will not be difficult to fasten the beacons - you need to put the pyramid from Alebasra, and then, carefully clicking on the lighthouse, align the top layer with a laser beam.

- If the overlap is not concrete, but from another material, then you will need to apply all your seamless and fantasy.

- Remember that the material of the beacon must coincide with concrete preparation material: for example, it can be a piece of bricks.

Varieties Floor screeding technology

Floor screed technology depends on what the overlap is and what exactly needs a construction team. It should also be noted that the price of filling the floor screed depends on the ways to perform work, the qualifications of the working and cost of materials.

Currently there are three technologies that are used to fill the floor screed:

- The traditional filling technology of the floor screed (it is also called "wet") - the cement mortar is used.

- Semi-dry film screed tie - inside use reinforcement, and water is only needed so that the elements of the leveling mixture should be swollen.

- Dry Floor Screed Technology - Using Building Materials in Plate: Plywood, Gypsum, etc.

Traditional technology

The traditional filling technology of the screed is to use a concrete or cement mixture by capital overlap .. Builders note that there are its secrets and rules of the device and work.

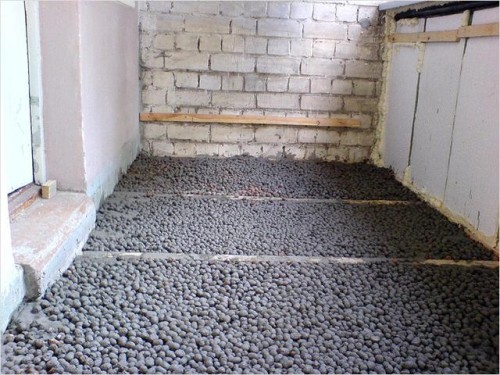

- In the event that during the determination of the floor level and installation of beacons, the coating drops are detected up to 10 cm, it is necessary to first fall asleep the floor with a grainzit or a domain slag.

- If you fall asleep the floor, note that the beacon must be no more than 2-3 cm.

- Before using clay, it needs to soak - it must be completely soaked with water.

- If you doubt how much time it is necessary to soak the clamzit, look at the surface of the water - as soon as the bubbles are missing, it means that it is completely soaked with water.

- Failure is best stacked by vibration worms so that there is no shrinkage when you do not expect it.

- If a concrete screed must be poured onto a concrete, then the floor must be pre-mixed so that the clutch of the solution is stronger.

- Ceramzite or slag must first be sprayed with cement "milk".

- In order for the fill of the flooring of the floor concrete was strong, you need to use sand either small gravel.

- Concrete or cement mixture is prepared identically - as for all other construction work.

- Perfect cement for a screed floor - brand 500.

- Fill the floor screed from the very far corner of the room.

- In the event that the pouring of the heating floor screed is performed, then before filling the concrete, it is necessary to make sure that the entire system works.

- The solution should be average - not steep, but not liquid, as it should be comfortably smooth.

- The surface must be smoked as they are filling with special rails (rules) - their length is approximately two distances between the beacons.

- At the time of frozen the screed, it is desirable to cover with wet sawdusts - this is the perfect solution.

16. 21 Day Chat (if there is no possibility to put the sawdust on it) you need to make water from time to time. - The frosting of cement is not the evaporation of moisture, but the reaction of cement with water - if the water is not enough, the surface will be continuing.

- The floor overlap can be mounted on the screed in a month.

- In the event that the screed from the cement should be on a wooden coating, it is necessary to protect the tree from the penetration of moisture: the floor is treated with bitumen mastic, put on top of the runneroid, join the bitume.

Semi-dry technology

Traditional technology is inferior in strength to other varieties, since it has one very large drawback: the fuel mixture has no basis in the form of reinforcement. What you can not say about semi-dry technology.

- The grid "Rabita" is not used for these purposes, since during fixing to the concrete base it is installed above the "warm floor", since the expansion coefficient in concrete and metal is completely different.

- The mixture from cement can be "attract" to the coefficient of the expansion of the metal - it is necessary to choose such a mixture, as part of which synthetic fiber (in this case, the fiber fiber is made to the cement-sand dry mixture, and then carefully squeezed).

- Thanks to the reinforcement, the floor will be durable and very reliable - it prevents shrinkage, much less cracking occurs, besides, it is necessary to solidify the screed much less time.

- The mixture that contains reinforcing fibers can only be sold in the finished form - to do it yourself unreal.

- To make a mixture to be ready, you need a little water - it is necessary in order for all components of Nobuchi.

- Despite the fact that in the instructions for the mixture it is written that waterproofing is not required, experts are advised to hold it, although the cost of filling the ball screed at the same time, but it is better to protect themselves.

Dry technology

Dry technology is considered the simplest of all varieties, however, it is very rarely used. This screed serves as an additional layer on the ceiling, so that it becomes durable and smooth. This technology allows in houses with wooden floors to put ceramic tiles.

- Before you begin to work, you need to pour dry ceramzit on the concrete overlap (you do not need to pull it out!).

- Ceramzit must get to the beacons.

- Tampering with vibrotrambobovka clamzit, it is necessary to pour it on top of it with cement mortar - there should be a small crust that secures the backbone.

- If the screed is installed indoors, where the increased humidity, it is necessary to make a layer of waterproofing (just between the backfilling and the first layer of the screed).

- Be sure to waterproofing is necessary between the screed and the draft floor, if the flooring is performed on wooden overlap.

- The waterproofing layer must be made by the "Vanest" on the walls, thus, the screed layer should be below the ends of the cloth insulation.

- Dry technology applies shields of a large area, for example, waterproof bakelite plywood (its red gluing composition).

- The overall layer that is used for plywood screed must have a thickness of at least 12 mm, but best, if there are several layers here - so that the seams are blocked by each other, and it is necessary to have the middle of that sheet on the suture.

- Watch that there was no floor deflection - the backfall for this should be as close as possible tamper.

- The dry screed can be based on a bakelite phaneer, and on top to put cement-chip plates or moisture-resistant drying sheet.

- It is not necessary to use moisture-resistant plasterboard, as it has a small strength.

- Do not forget to close all seams to sealants on silicone or polyurethane.

- Dry base should not be adjusted to the wall, as it will become an additional source of sound indoors.

- All over the perimeter of the room, it is necessary to leave a gap of 10 mm - it can be easily overlapped with a plinth.

- In the left, the slot will need to be laid mineral wool or fiberglass - but there should be no contact of the walls with a screed - otherwise the vibration of the walls of the floor coating will not be transmitted.

- Hypus fiber plates and bakelite fane can be drilled, process tools, as well as glue any coating on them with construction glue.

Start a discussion ...

Start a discussion ...